A high-efficiency high-energy light photoelectric conversion material and its manufacturing method

A photoelectric conversion material and high-efficiency technology, applied in the field of solar photoelectric materials, can solve problems such as lack of resources, inappropriate opening of other resource projects, and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

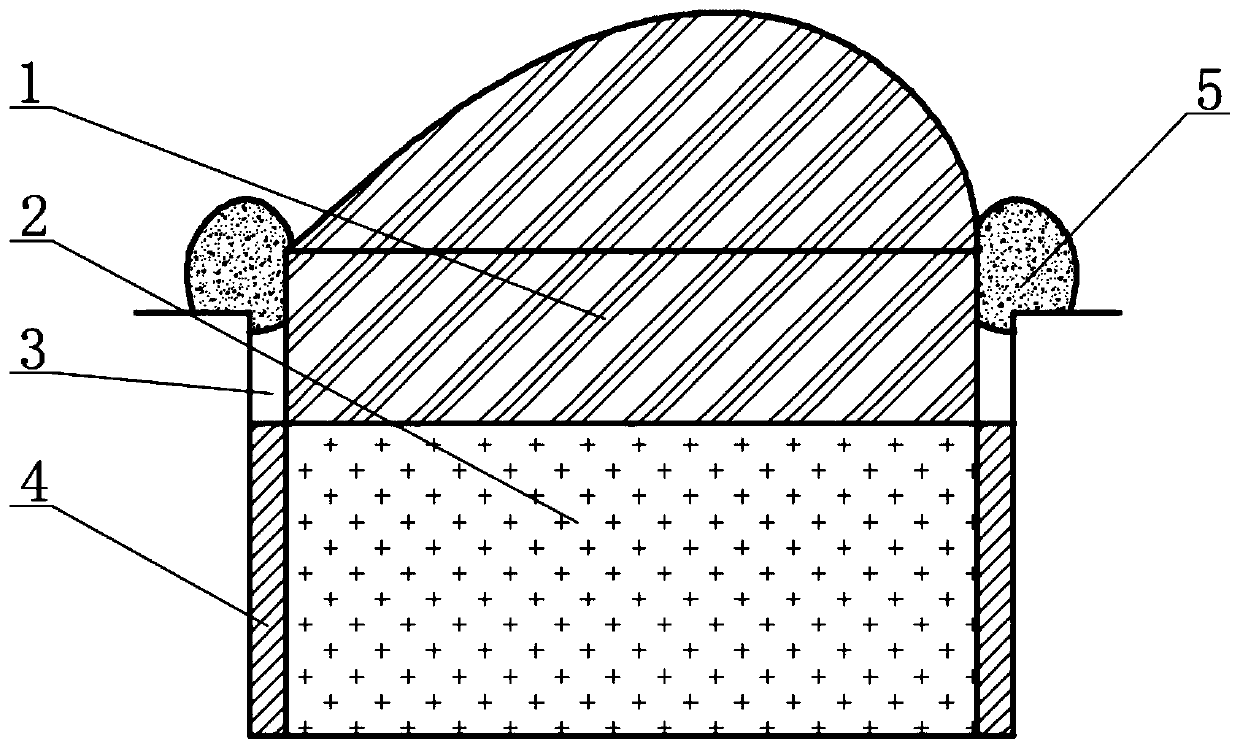

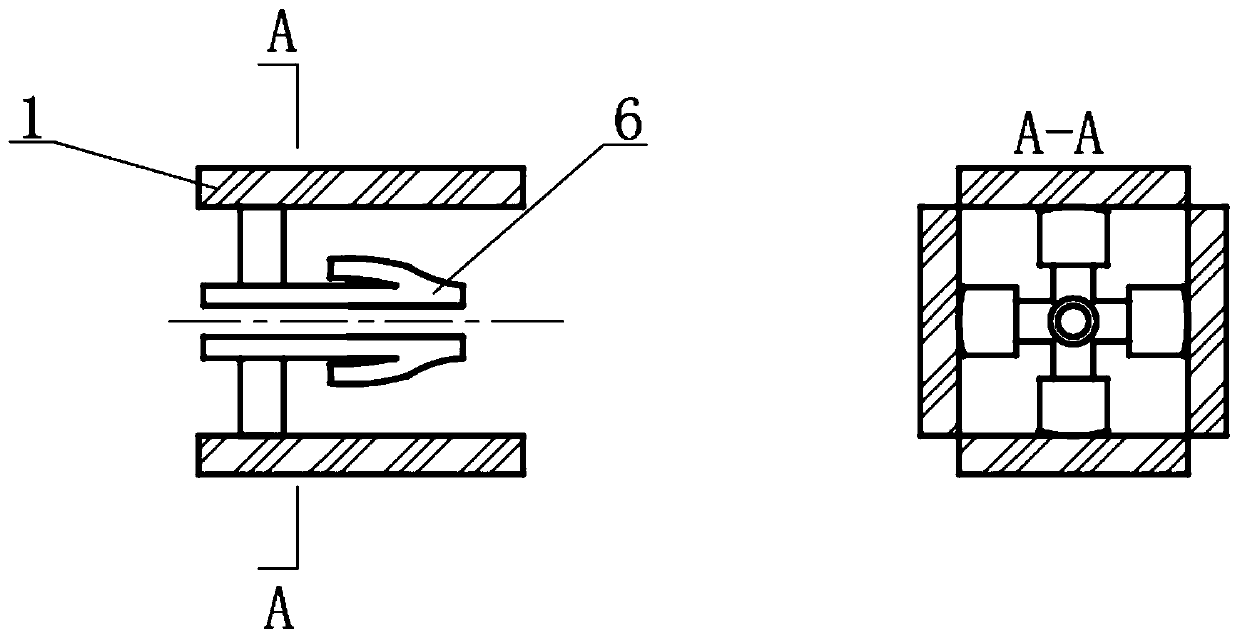

[0027]A high-efficiency and high-energy light photoelectric conversion material, including a glass cover 1, a solar cell 2 whose upper surface is tightly glued to the bottom of the glass cover 1 by EVA, and a mounting groove 3 for fixing the glass cover 1 and the solar cell 2, characterized in that : the glass cover plate 1 is a double-layer glass, wherein the lower layer of glass is a high light-density glass (high light) with a refractive index nd value of 1.80-1.81 made of lead oxide, silicon dioxide, sodium carbonate, potassium nitrate, and strontium oxide as a raw material The formula of the dense glass is based on the existing technology, and the dosage and purity of lead oxide, sodium carbonate, potassium nitrate, and strontium oxide are adjusted to increase the refractive index and reduce the light transmittance, so a special description is made), the upper layer of glass is the refractive index Low optical density glass with an nd value of 1.50-1.53 (the formulation ...

Embodiment 2

[0044] The whole is consistent with Example 1, the difference is:

[0045] 1) Preparation of lower vitreous body

[0046] ① Prepare the following raw materials by weight: lead oxide 73Kg, silicon dioxide 26Kg, sodium carbonate 1.4Kg, potassium nitrate 2.2Kg, strontium oxide 0.4Kg, all raw materials are analytically pure;

[0047] 2) Preparation of upper vitreous body

[0048] ①Prepare the following raw materials in terms of molecular weight: 85Kg of silicon tetrafluoride, 3Kg of sulfur hexafluoride, 3Kg of dicarbon tetrafluoride, 8Kg of boron oxide, sufficient amount of high-purity oxygen with a purity of not less than 99.99%, defoaming Dosage 0.2Kg;

[0049] The present invention is only part of the structure for light energy absorption, and needs to be matched with other matching structures (such as cables, aluminum alloy frames, rotating structures, etc.) The lower layer is 87.5%), and the average absorption rate of light energy is 34.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com