Pipeline ball valve for crude oil delivery based on differential pressure extraction and siphon complete discharge

A siphon and pipeline technology, applied in the direction of siphon pipes, valve devices, cocks including cutting devices, etc., can solve the problems of reducing pipe diameter, counting deviation, reducing control flexibility, etc., to achieve the effect of ensuring flexibility and reducing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

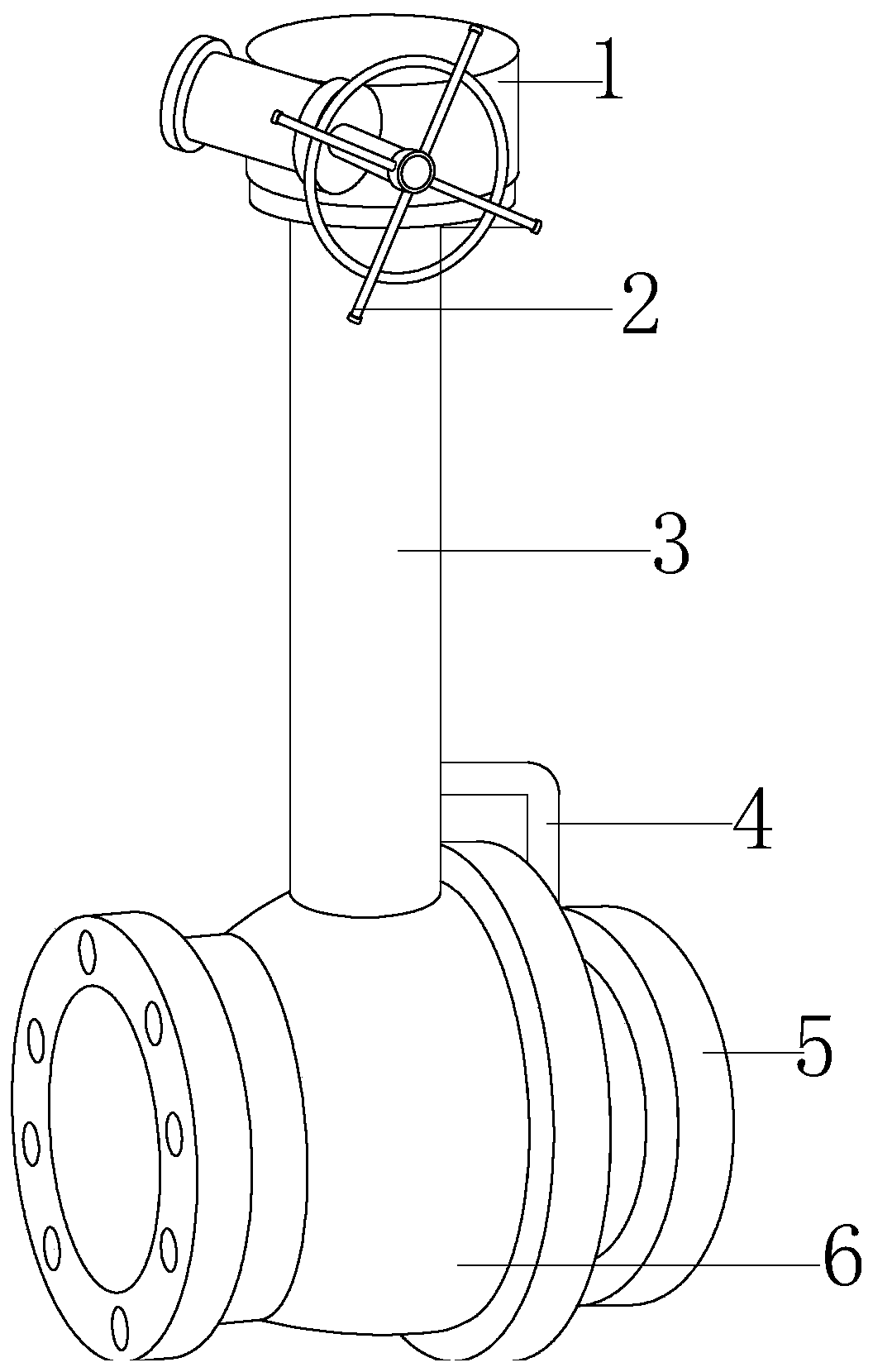

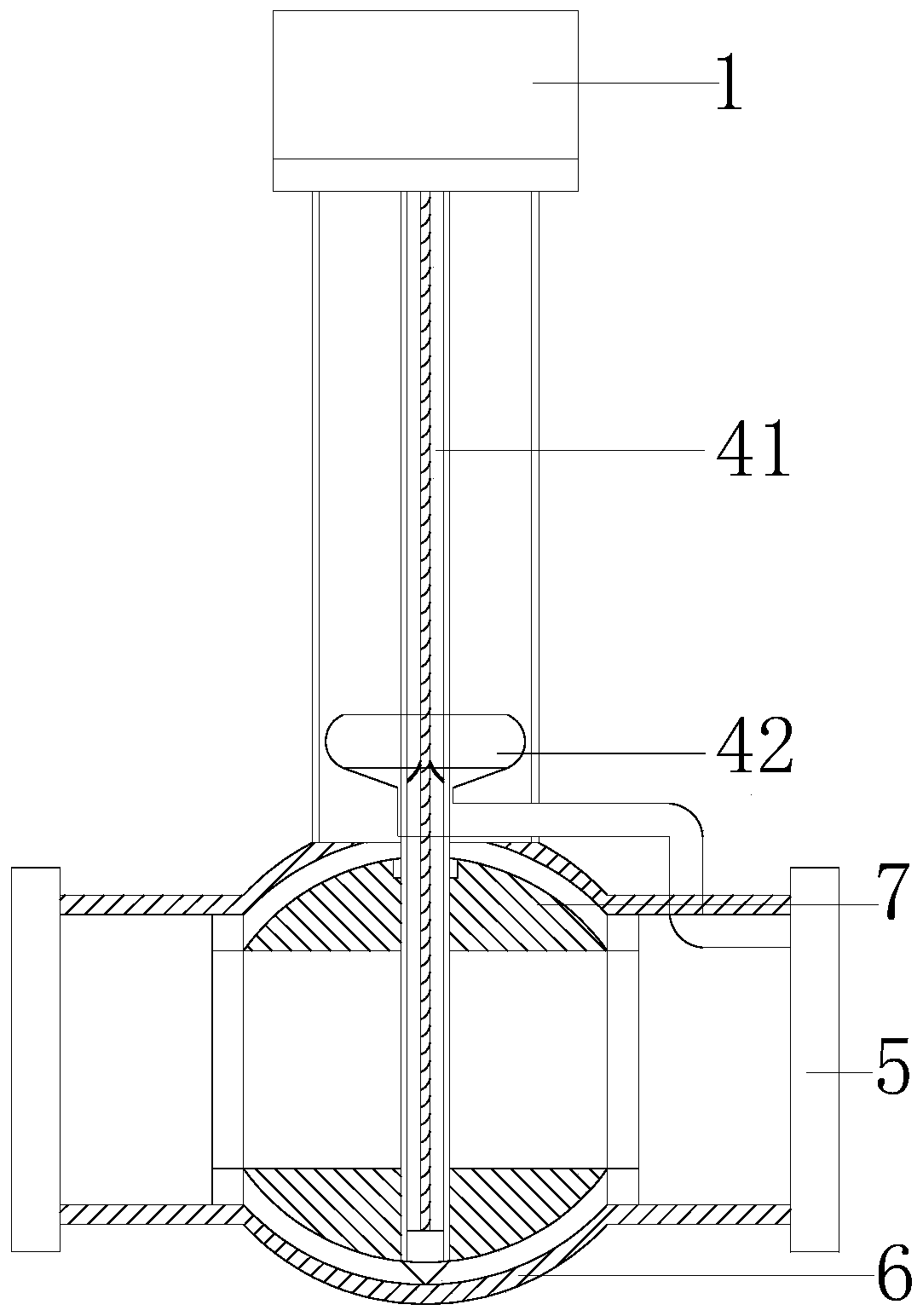

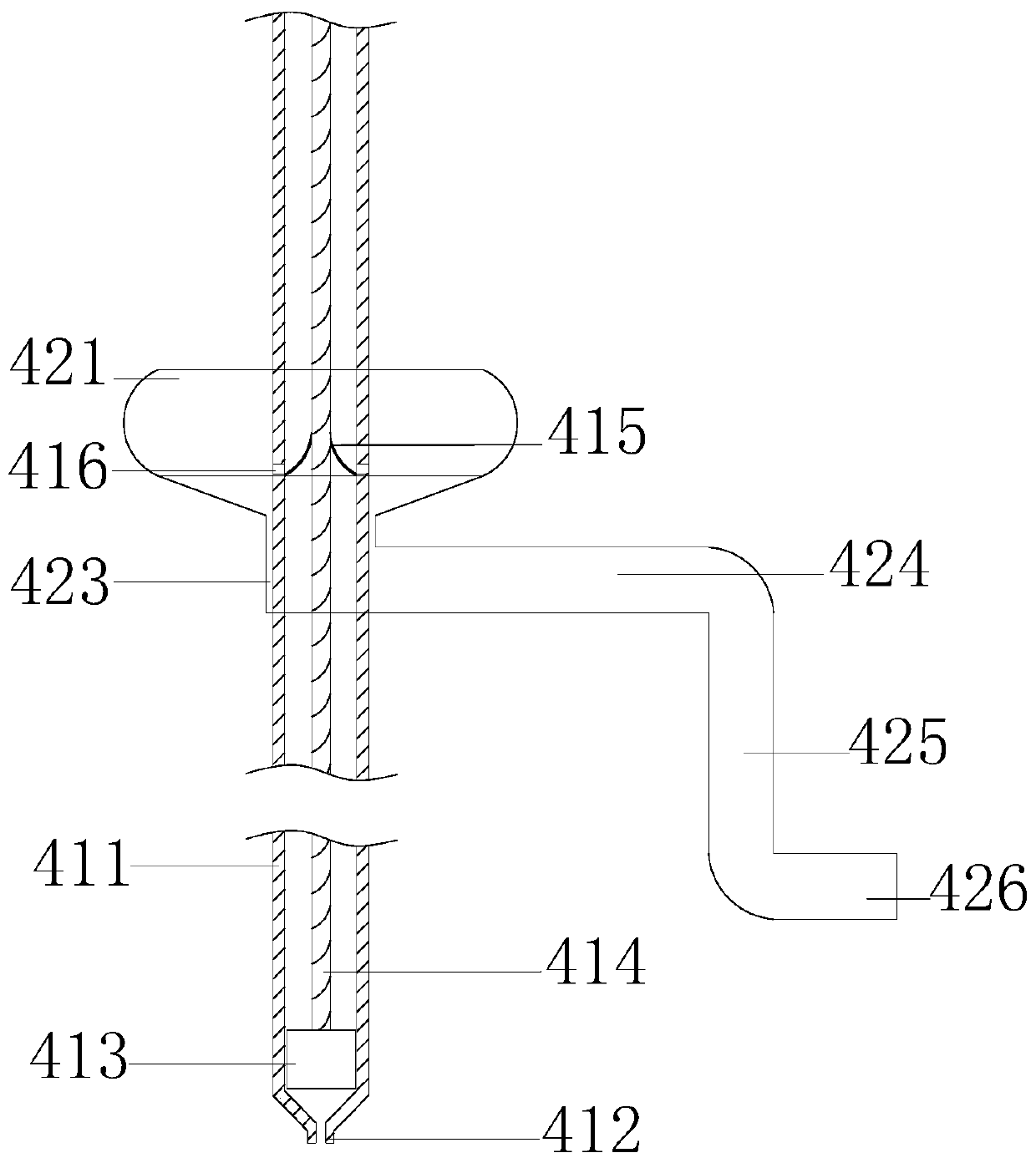

[0028] Such as Figure 1-Figure 4 As shown, the present invention provides a technical scheme of a pipeline ball valve for crude oil transportation based on differential pressure extraction and siphon exhaustion:

[0029] A pipeline ball valve for crude oil transportation based on differential pressure extraction and siphon exhaustion, the structure of which includes an actuator 1, a control hand wheel 2, a valve stem 3, a suction exhaustion device 4, a connecting flange 5, a valve body 6, a ball 7. The executive mechanism 1 is set on the upper end of the valve stem 3, the control handwheel 2 is engaged and movably connected with the actuator 1, and the suction exhaust device 4 is set inside the valve stem 3 and connected through electric welding....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com