A microchannel heat exchanger

A micro-channel heat exchanger and micro-channel technology, applied in heat exchange equipment, lighting and heating equipment, evaporator/condenser, etc., can solve the problems of not solving the drainage problem of the evaporator and reducing the heat exchange efficiency , to achieve the effect of solving drainage problems, improving heat exchange efficiency and optimizing design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

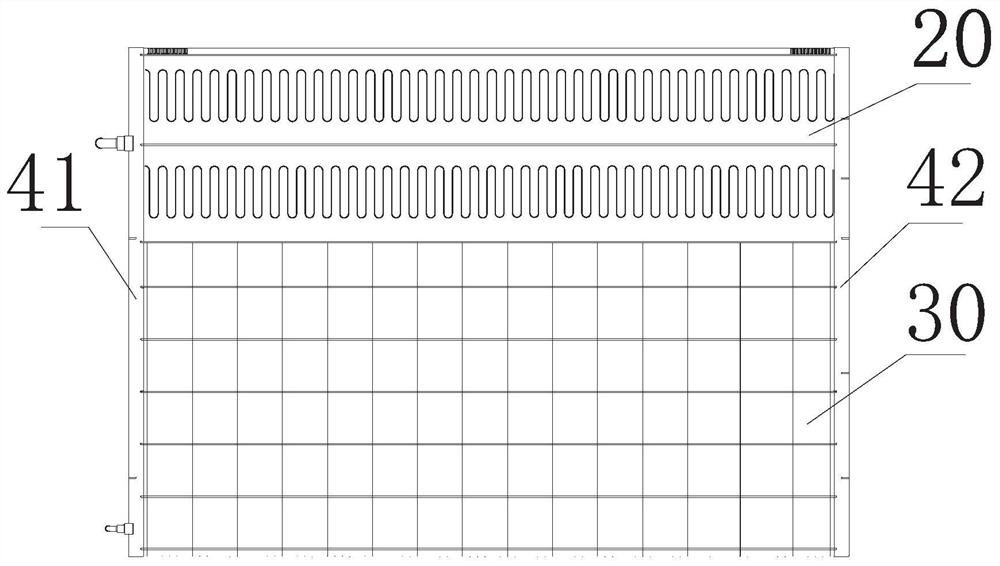

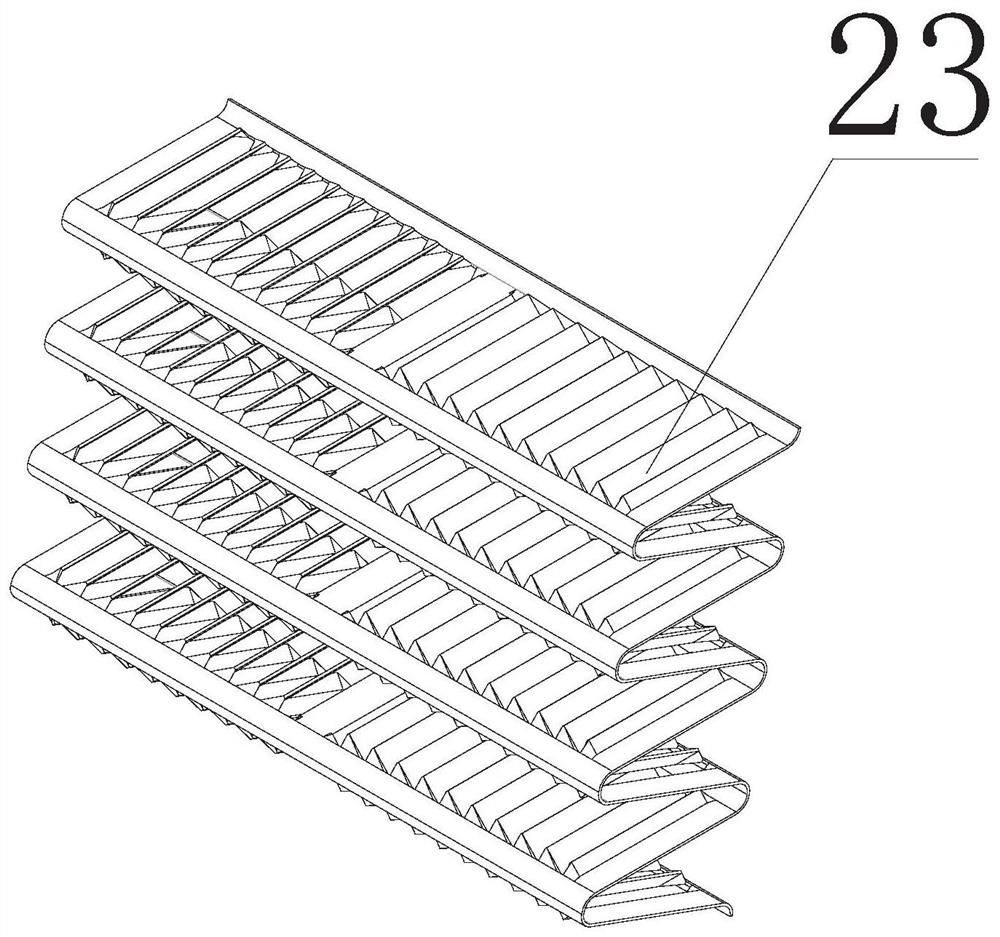

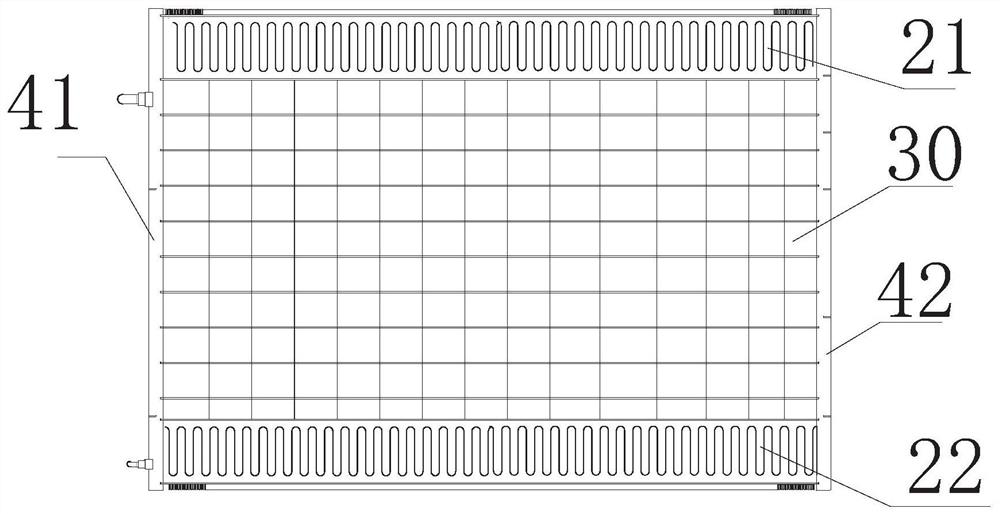

[0028] Please refer to Figure 1 to Figure 10 As shown, according to the embodiment of the present invention, the microchannel heat exchanger includes a plurality of flat tubes (not shown in the figure) for transporting refrigerant, the first heat dissipation part 20 and the second cooling part 20 arranged adjacently on the flat tubes. Two heat dissipation parts 30, the first heat dissipation part 20 has a plurality of corrugated microchannel heat dissipation fins 23, the second heat dissipation part 30 includes a plurality of plug-in fins, each of the plug-in fins The sheet has a flat tube groove for placing a flat tube, a part of the flat tube is embedded in the flat tube groove, and the other part of the flat tube is arranged between two adjacent microchannel cooling fins 23 In terms of heat dissipation, the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com