Compliant hinge stress measuring device

A compliant hinge and stress measurement technology, applied in the direction of measuring devices, electromagnetic measuring devices, measuring force, etc., can solve the problems of high cost, difficulty in obtaining quantitative experimental data, complex photoelastic measurement experiments, etc., and achieve convenient and easy installation , Highly reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

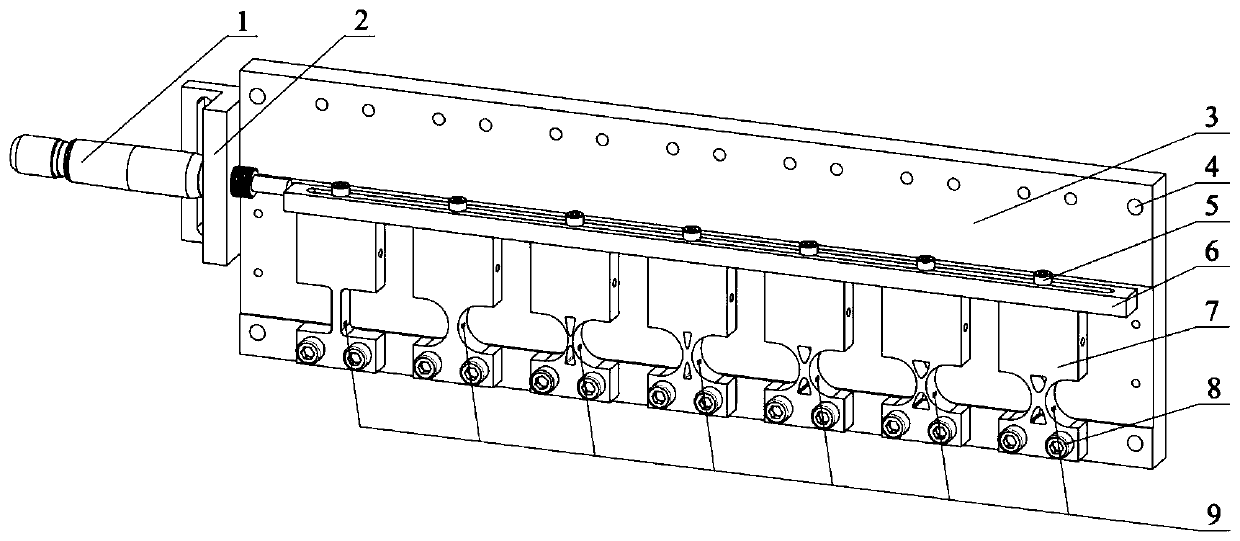

[0028] Such as figure 1 As shown, a compliant hinge stress measurement device, including:

[0029] Base 3, the edge of the base 3 is provided with a number of screw holes along the length direction to connect the fixed ends of the compliant hinge 7 to be tested by bolts. This embodiment reserves threaded holes for 7 hinge installation experiments. If necessary, increase the measurement hinge Quantity, only need to lengthen the base and multi-process the screw holes for hinge installation, and at the same time, the base 3 is fixed on the vibration isolation table through the through holes 4 on the four corners;

[0030] The spiral micrometer support 2 is fixedly arranged at one end of the base;

[0031] The spiral micrometer head 1 is threadedly connected with the spiral micrometer head support 2, and the precision is 0.01mm;

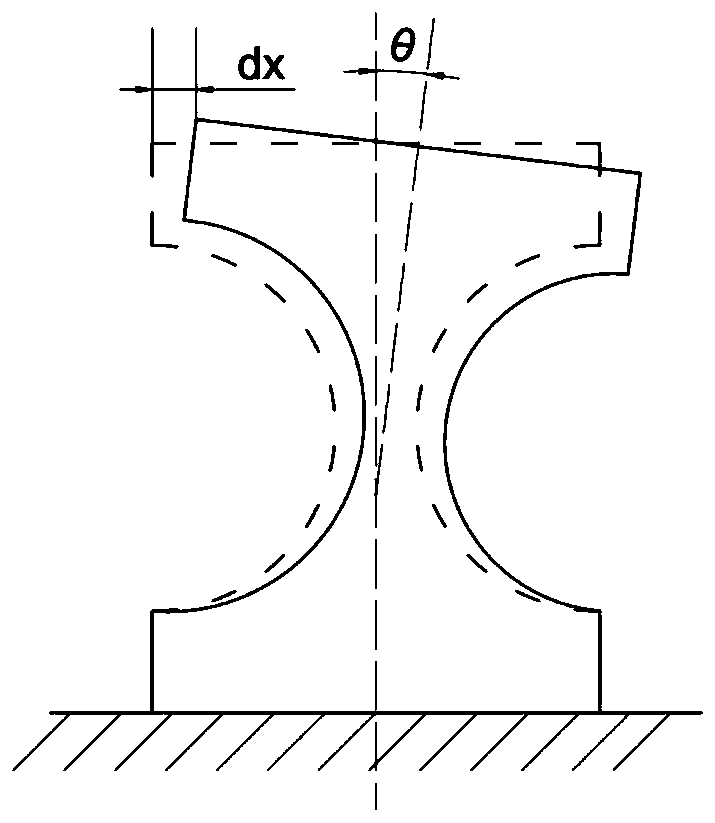

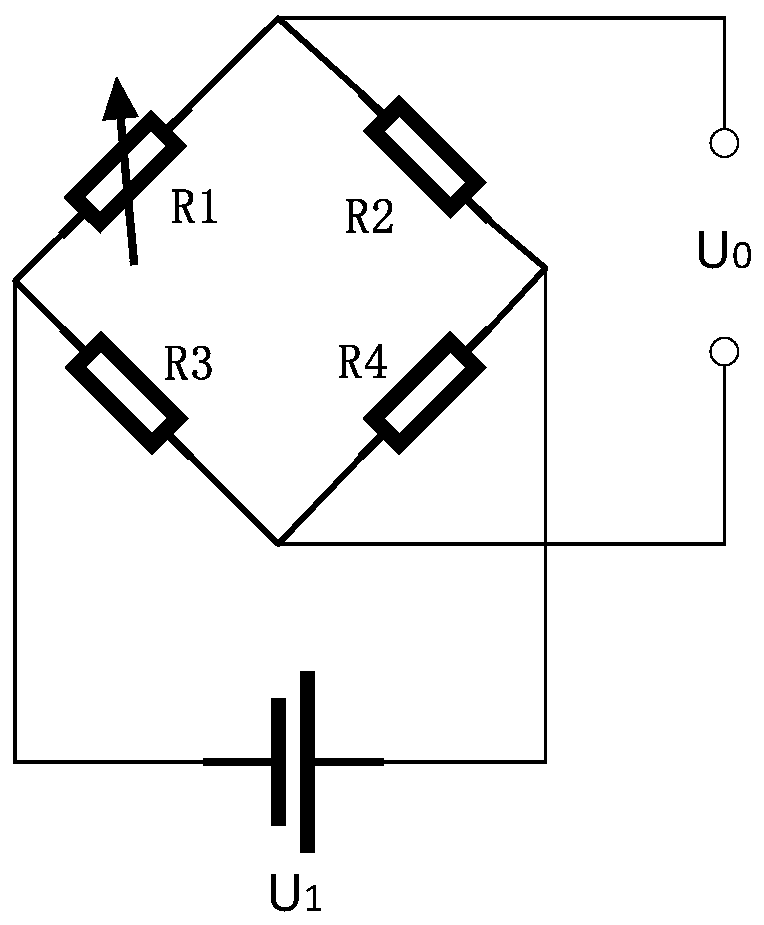

[0032] A long strip, o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com