Rapid calculation and design method for radial sliding bearing with axial pressure difference

A technology of radial sliding and design methods, applied in computer-aided design, calculation, design optimization/simulation, etc., can solve problems such as large amount of calculation and complicated design steps of radial sliding bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention is described in further detail below in conjunction with accompanying drawing:

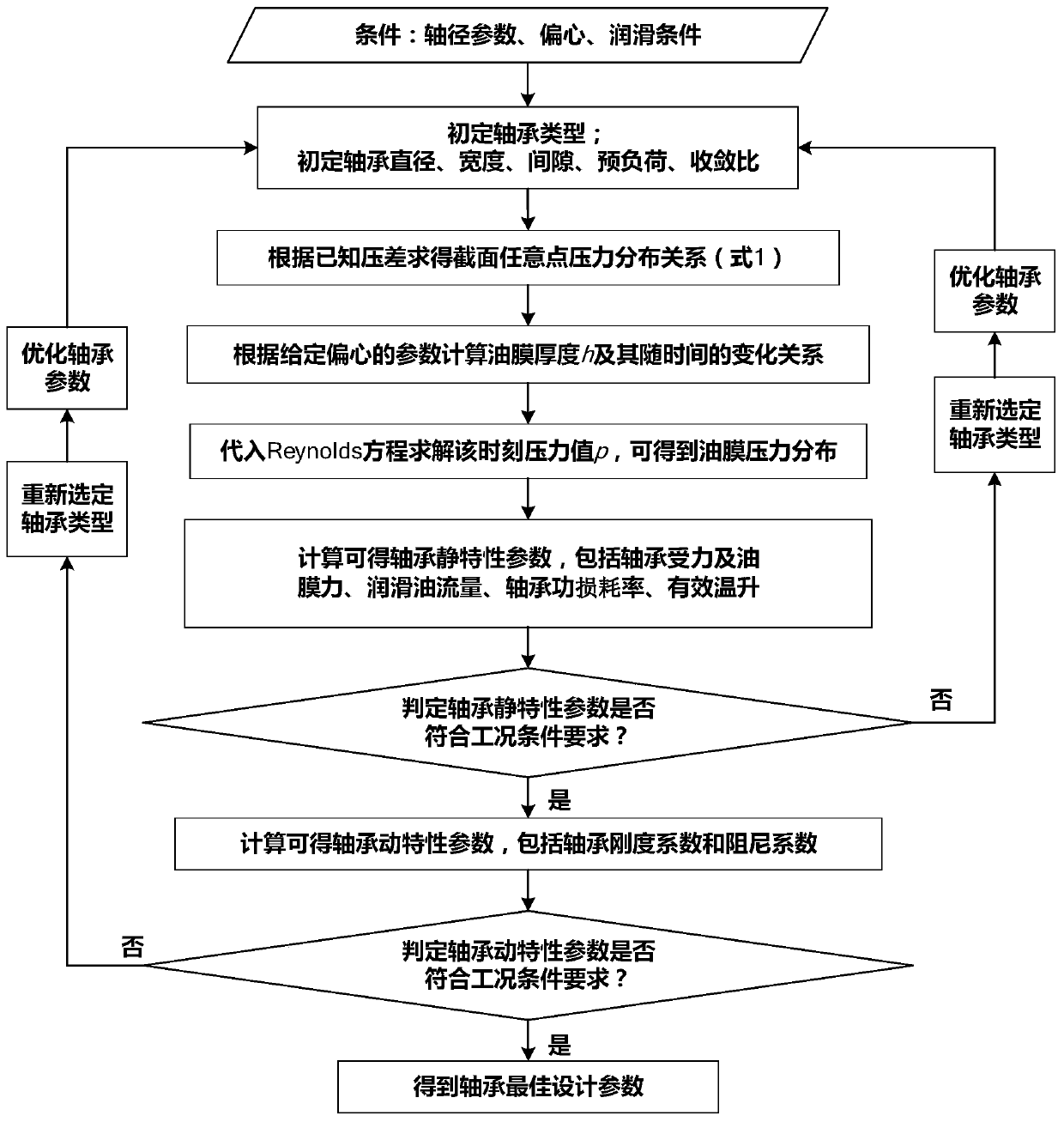

[0057] Such as figure 1 As shown, the present invention provides a rapid calculation and design method for radial sliding bearings with axial pressure difference, including the following steps:

[0058] 1) According to the known shaft diameter parameters, eccentric parameters and lubrication parameters of the radial sliding bearing, the specific type of bearing is initially selected; and then the various designs including bearing diameter, width, clearance, preload and convergence ratio are selected parameter.

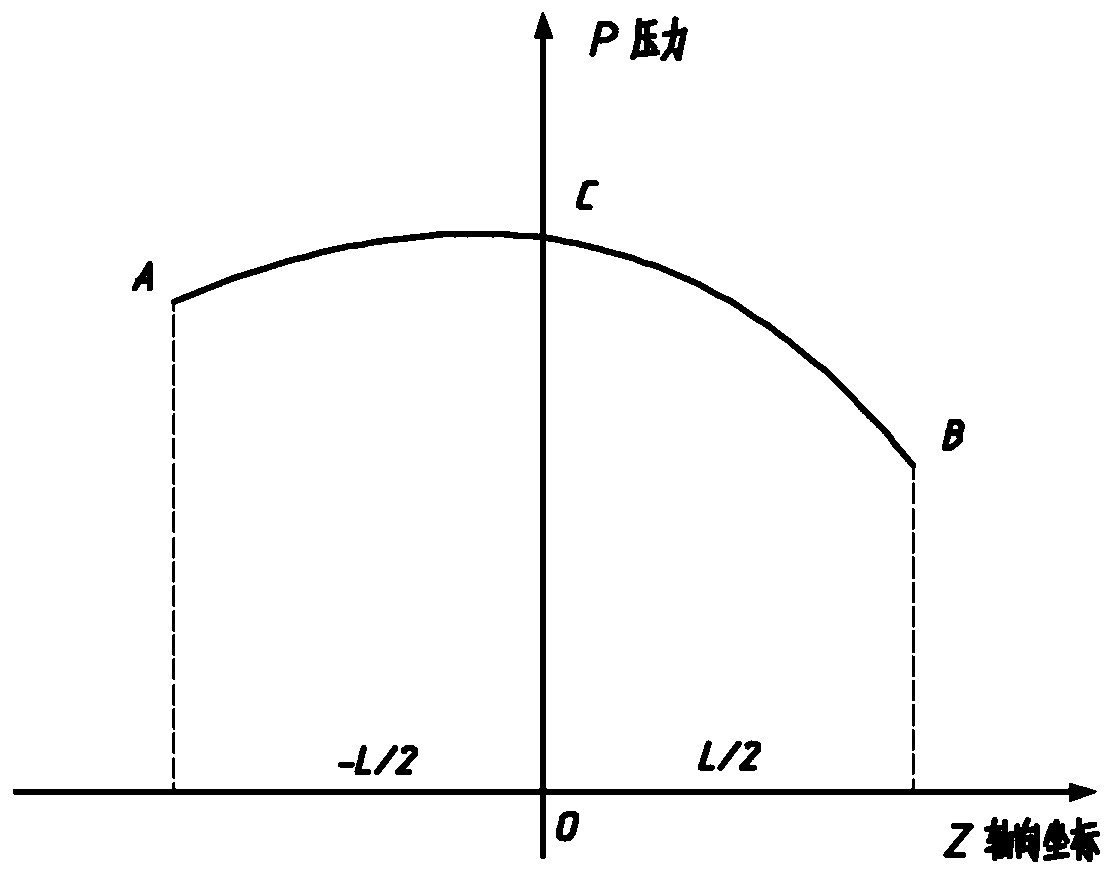

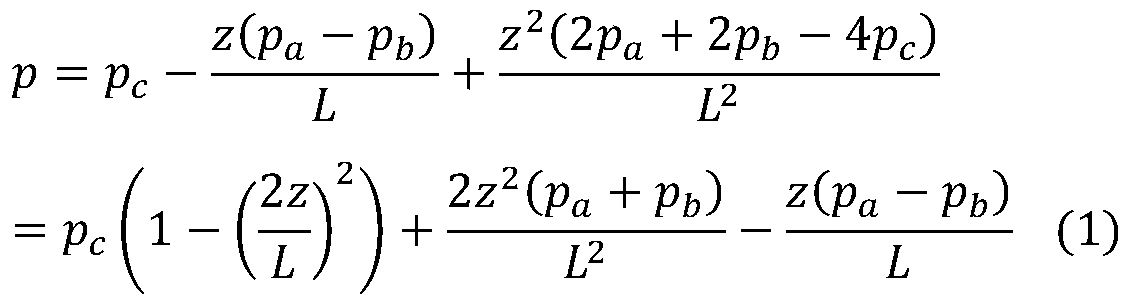

[0059] 2) Take the radial center section of the radial sliding bearing, whose circumferential coordinate is x and axial coordinate is z. The axial pressure distribution of the radial center section is as follows figure 2 shown. In the figure, point A represents the upper end surface of the bearing, and the coordinates are Point B represents the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com