Method for encapsulating vulnerable elements determined in printed board component under effect of dynamic load

A technology of dynamic load and packaging method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve the problems that cannot fully consider the factors affecting the vibration vulnerability of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

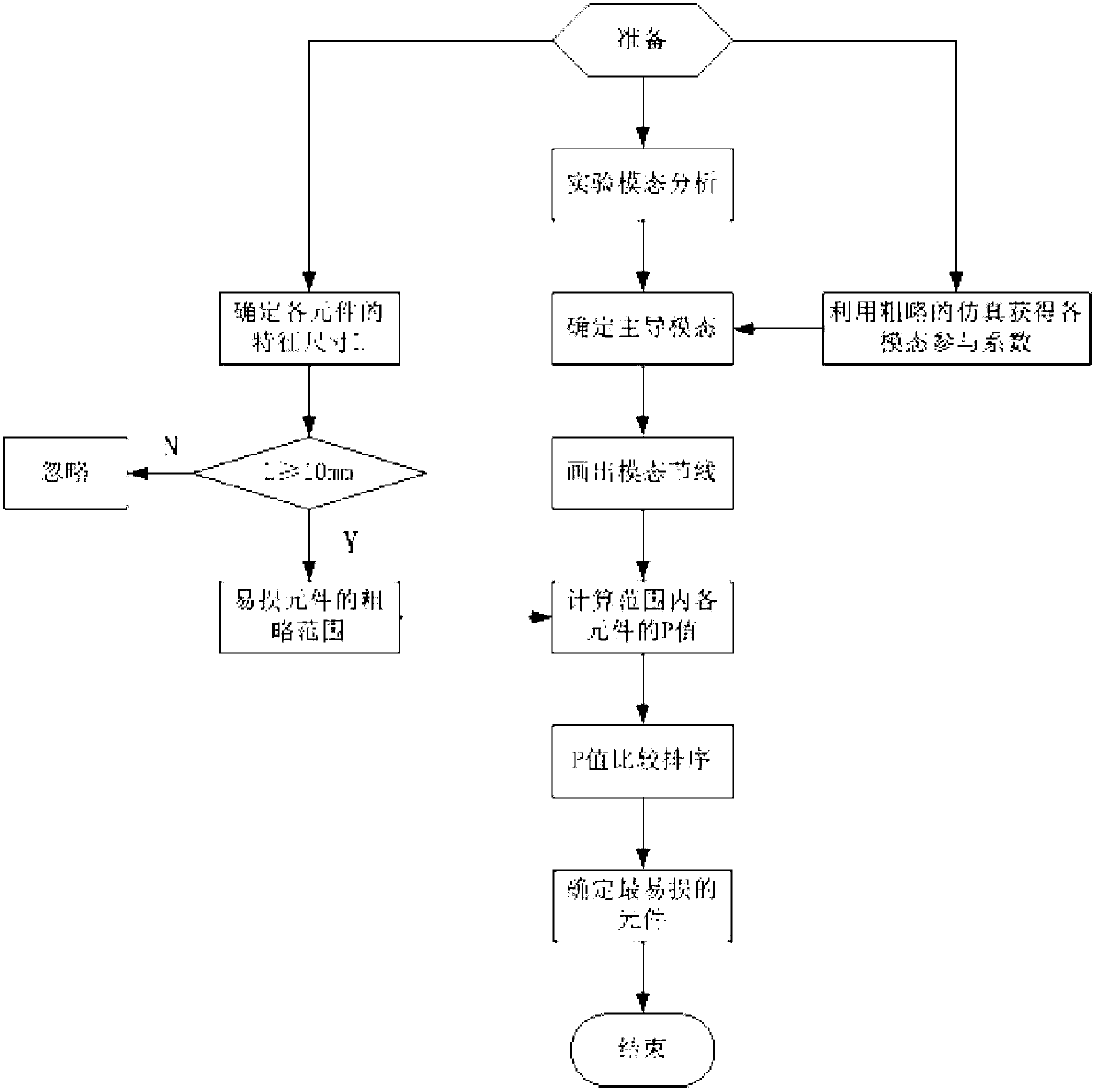

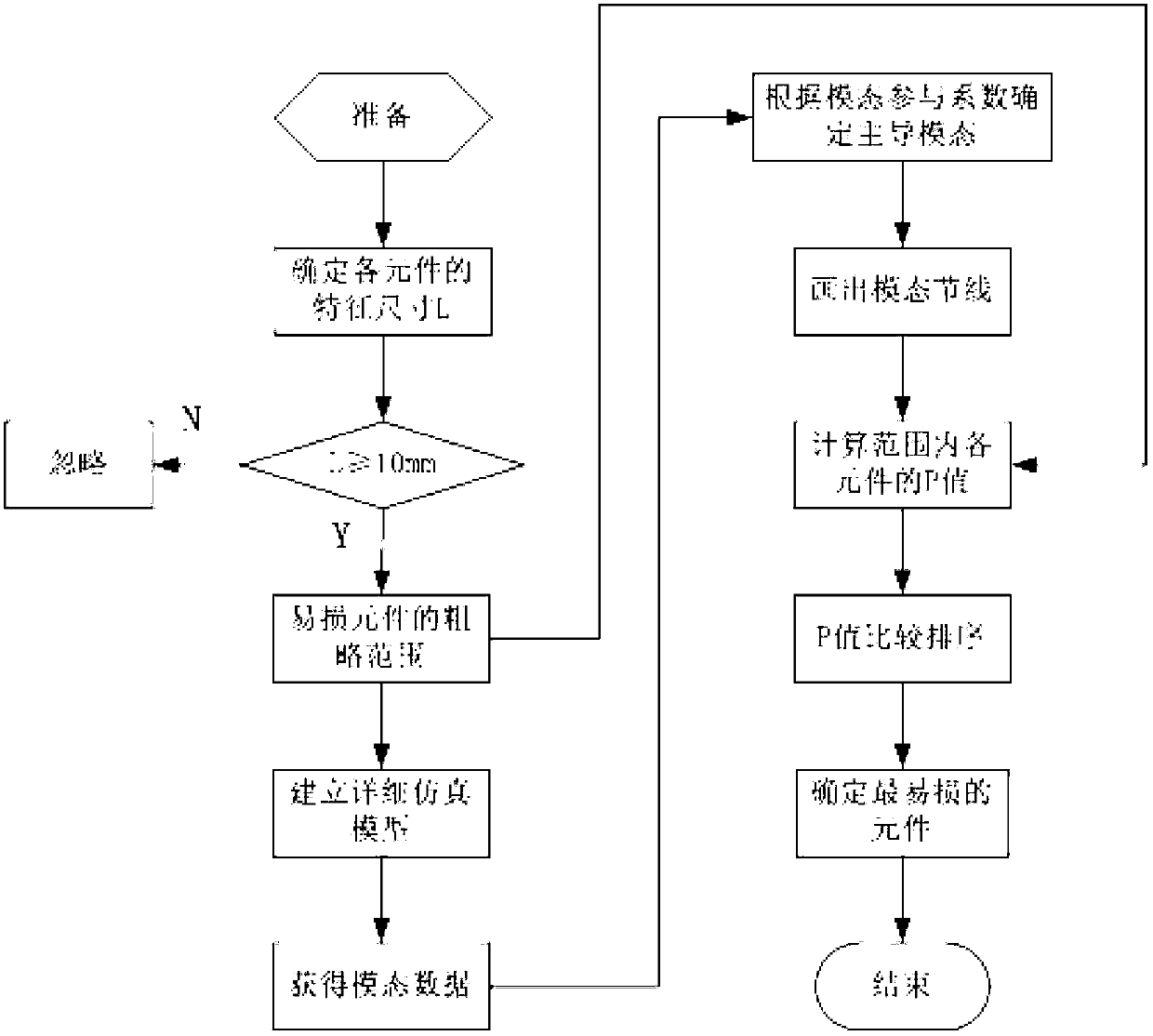

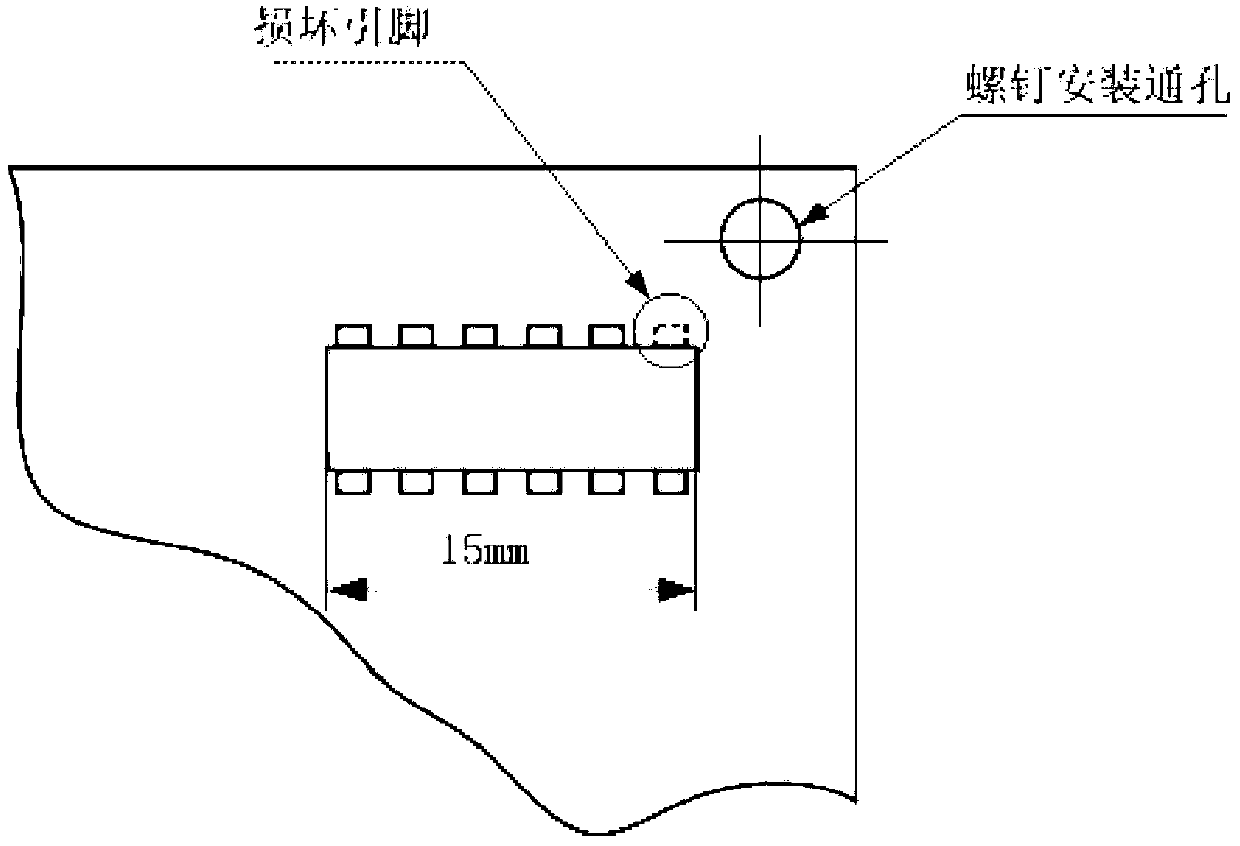

[0039] In the following embodiment of the packaging method for determining vulnerable components in printed board assemblies under the action of dynamic loads, according to the present invention, firstly, using the element characteristic size threshold value and the number of times it is traversed by the dominant mode node of the printed board assembly, Comprehensively judge the vibration vulnerability of components in printed board assemblies. Use the feature size threshold of the component to roughly determine the range of vulnerable components in the printed board assembly, and then check the number of times each component in the determined range is passed by the node line of the dominant mode of the printed board assembly, and then introduce the vulnerable components The P value of the property index is used to evaluate the vulnerability of components. The vulnerability index P of each component is calculated by using the data that the nodal line of the dominant mode passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com