Printhead having a temperature-control device

A temperature control device and temperature control technology, applied in viscosity control, valve device, inking device, etc., can solve the problems of high viscosity of coating medium, low viscosity of coating medium, unfavorable continuous production, etc., and achieve high on/off frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

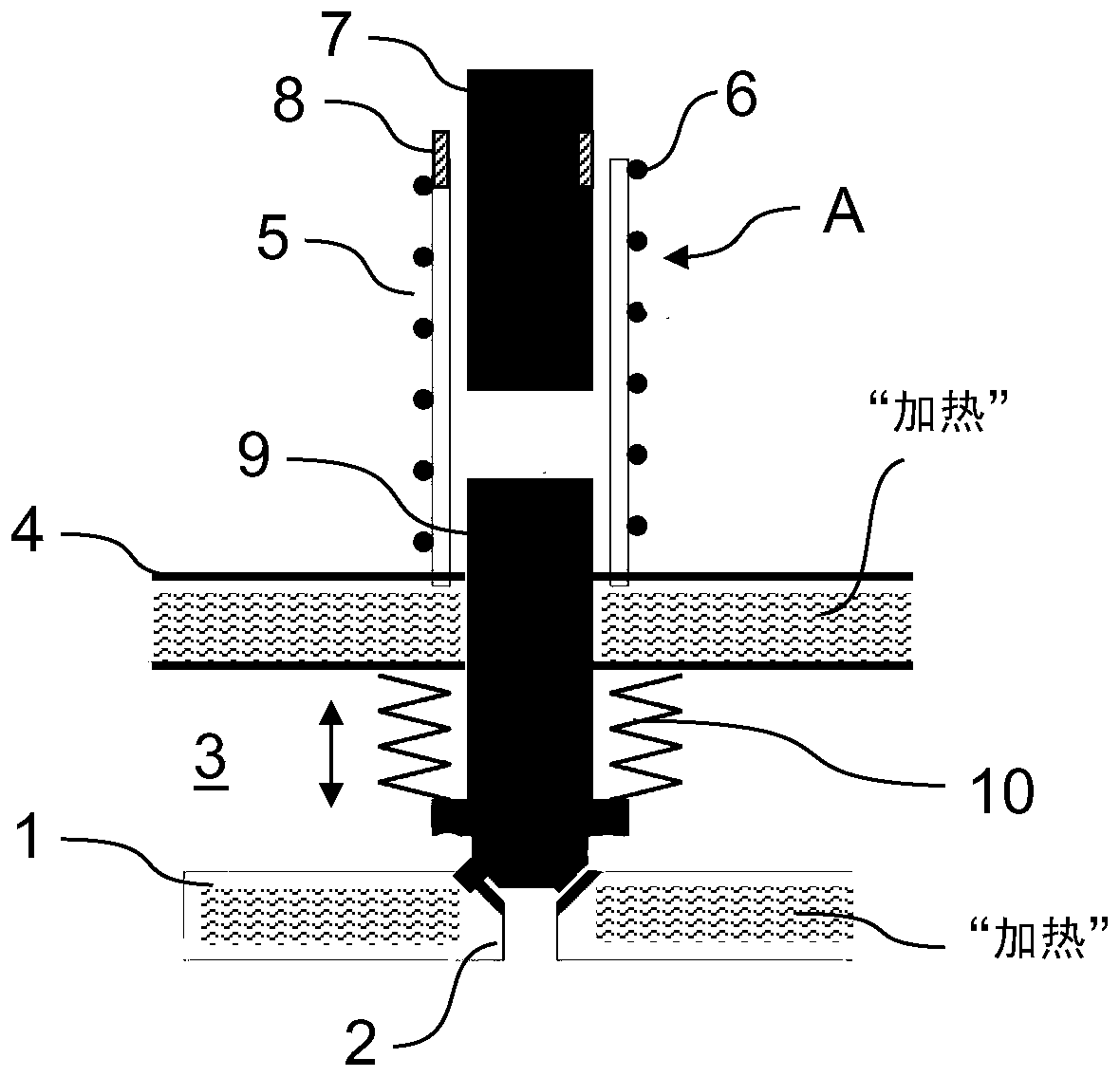

[0082] Partially corresponding preferred embodiments of the invention are described with reference to the figures, wherein similar or identical parts bear the same reference numerals, and for the sake of explanation, reference is also made to the description of other embodiments or figures to avoid repetition.

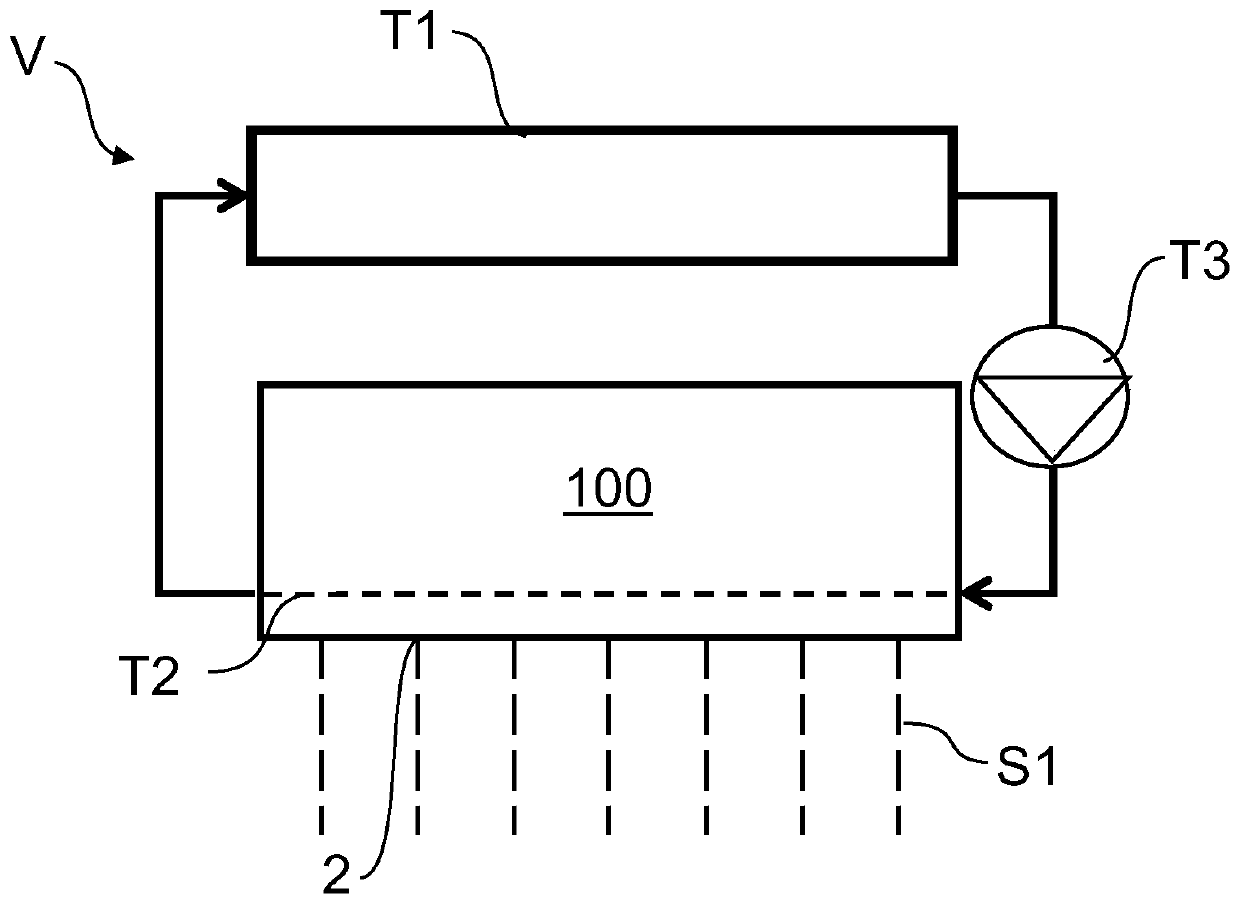

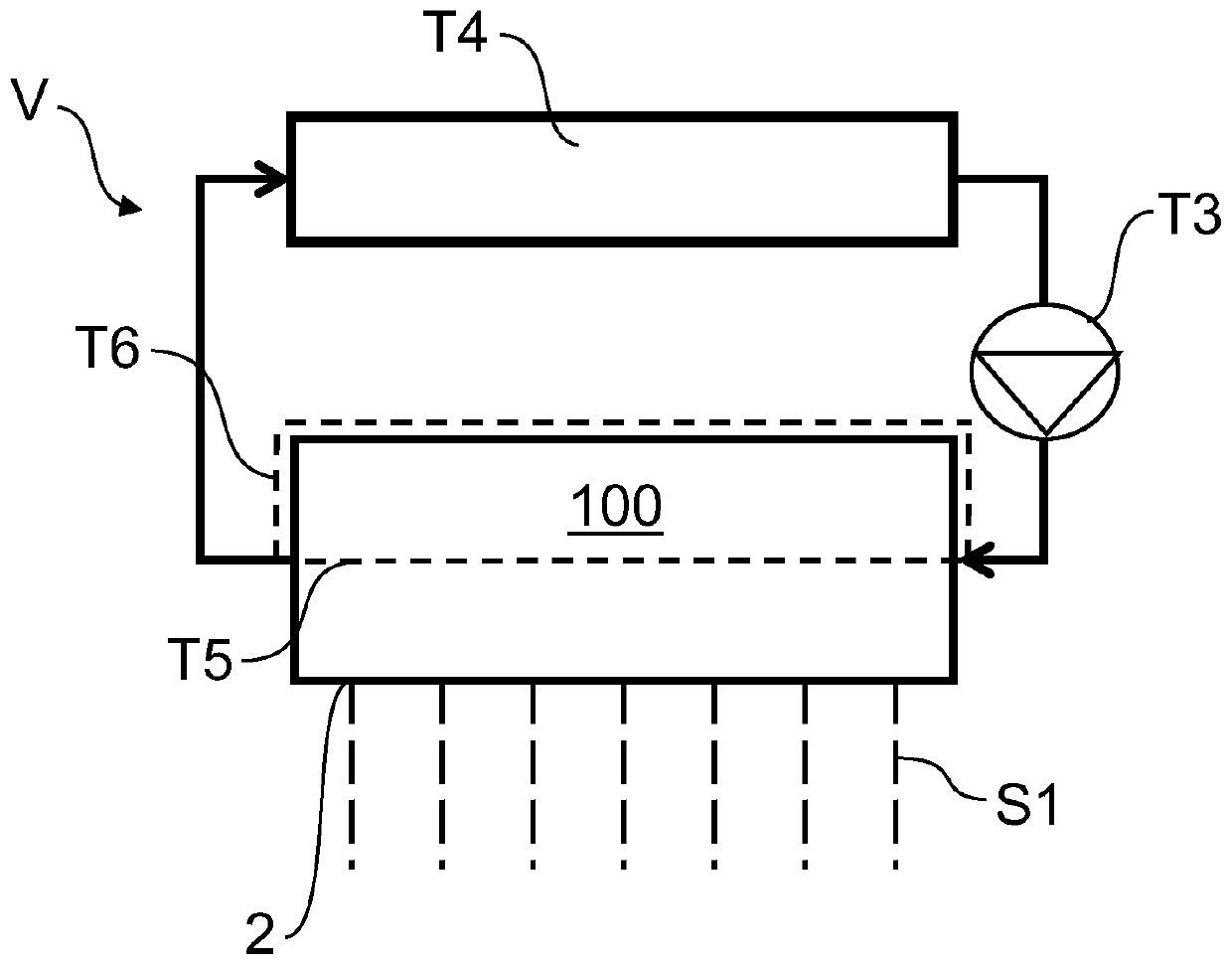

[0083] figure 1 A schematic diagram of an application device V having a printing head 100 according to an embodiment of the present invention is shown, wherein, image 3 A schematic / detailed view of a portion of printhead 100 is shown. The application device V, especially the jet printing head 100 is hereinafter combined figure 1 and 3 to describe.

[0084] The application device V is used for applying a coating medium to components, in particular for applying paint to motor vehicle body parts. For this purpose, the application device V includes in particular a printing head 100 for the continuous, continuous and substantially atomized and spray-free application of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com