Circular grain drying device

A drying device and grain technology, applied in the direction of drying and preserving seeds, can solve the problems of low drying efficiency, complex drying structure, and cumbersome drying process, etc., to achieve strong power, improved efficiency, and stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

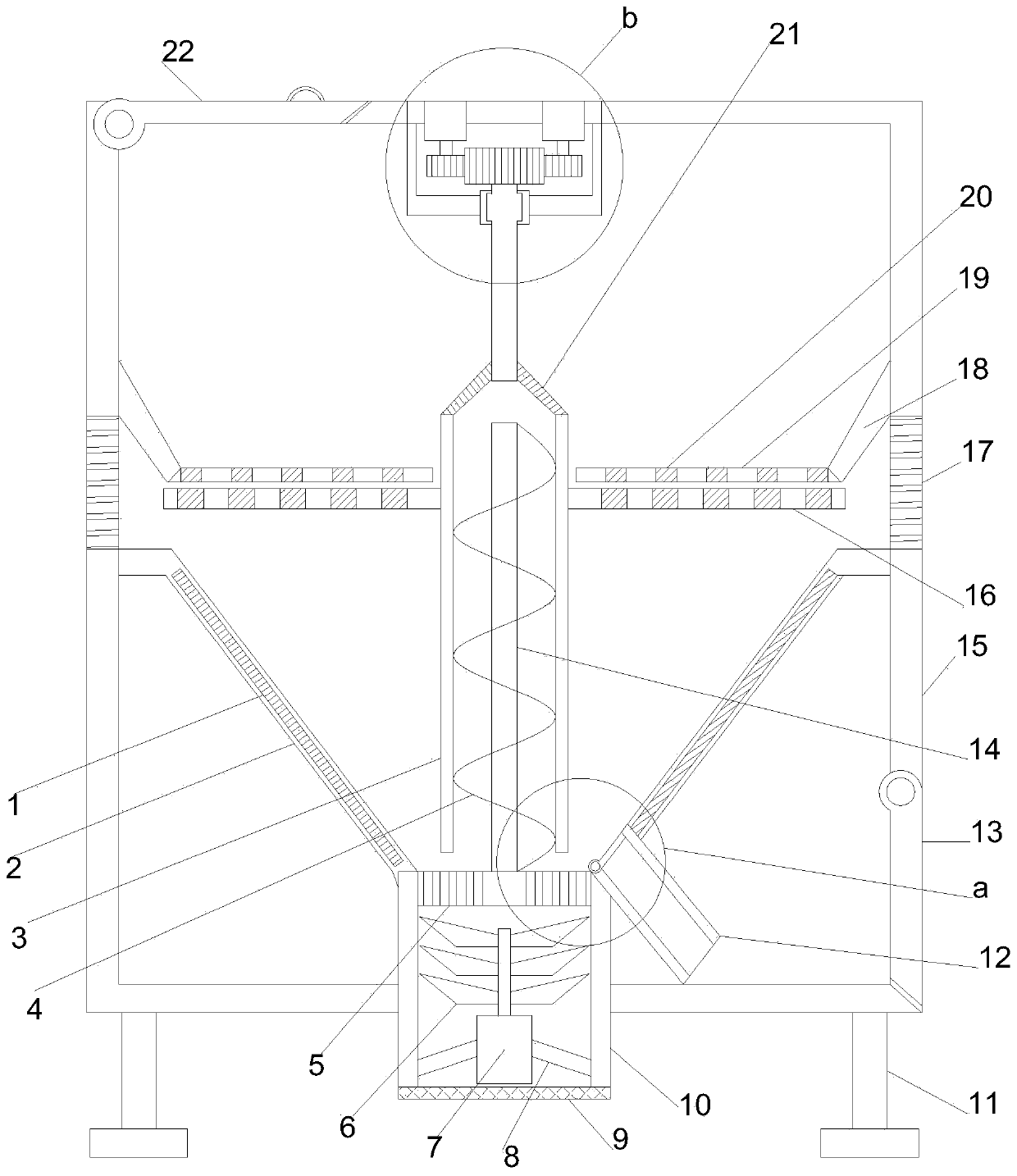

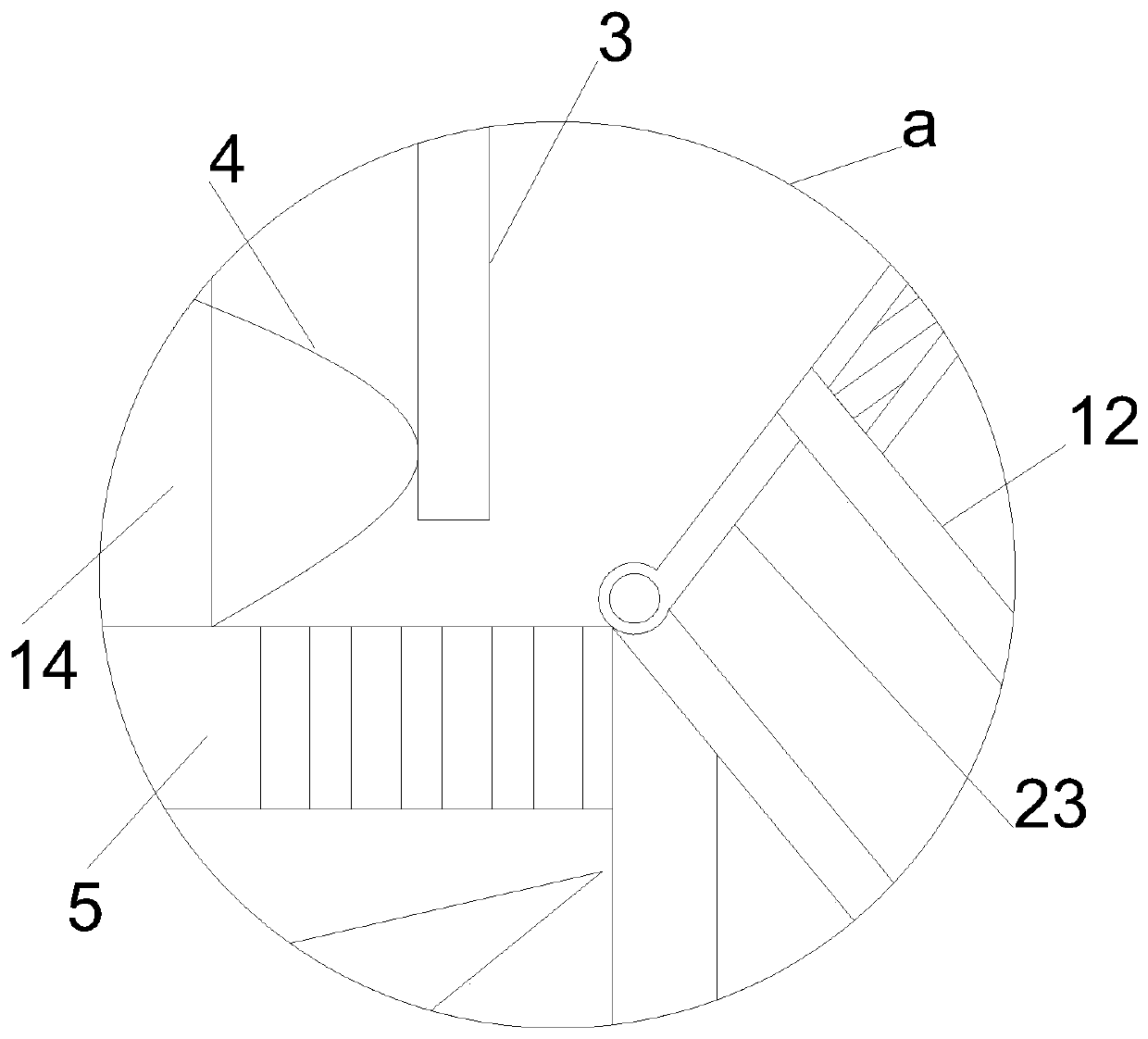

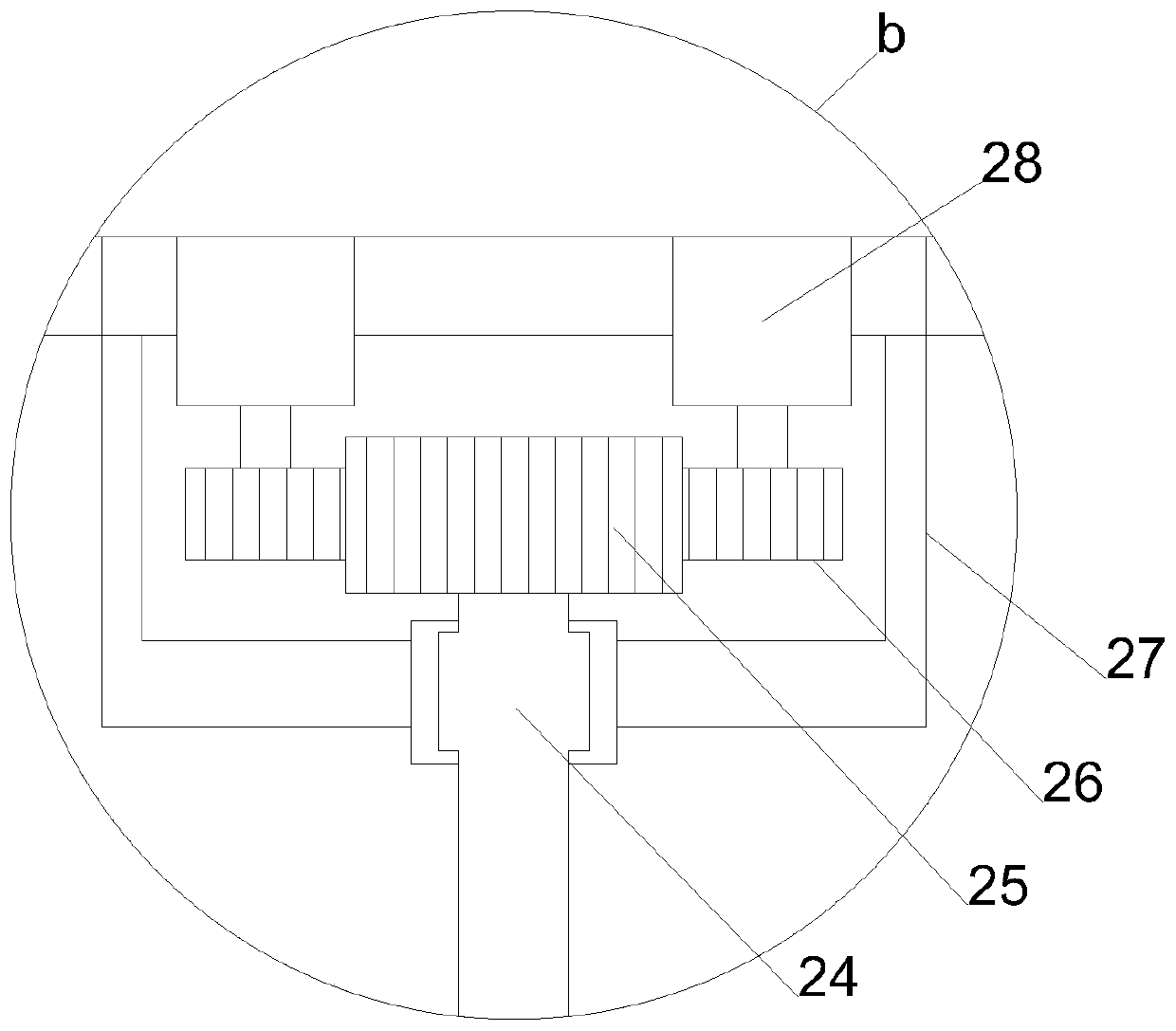

[0023] See Figure 1~4 In the embodiment of the present invention, a grain circulating drying device includes a support mounting cylinder 15 arranged vertically, a plurality of support mounting columns 11 are arranged at the lower end of the support mounting cylinder 15 at an equal angle, and the upper left corner of the support mounting cylinder 15 is horizontally arranged There is a feed gate 22, a discharge gate 13 is vertically provided at the lower right corner of the support mounting cylinder 15, a transmission mounting cover 27 is provided at the middle position of the upper end of the support mounting cylinder 15, and a guide is vertically provided at the lower middle position of the support mounting cylinder 15 The upper end of the flow guide installation cylinder 10 is vertically provided with a tapered material guide tube 2, and the upper end edge of the tapered material guide tube 2 is connected to the inner wall of the support installation tube 15. An electric auxi...

Embodiment 2

[0026] On the basis of the first embodiment, the air-guiding efficiency of the device is increased by the annular exhaust holes 17 arranged in a row, thereby improving the efficiency of dehydration and further improving the drying efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com