A kind of magnesium alloy surface modification process

A surface modification, magnesium alloy technology, applied in the field of magnesium alloys, can solve problems such as increasing the galvanic corrosion tendency of the film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

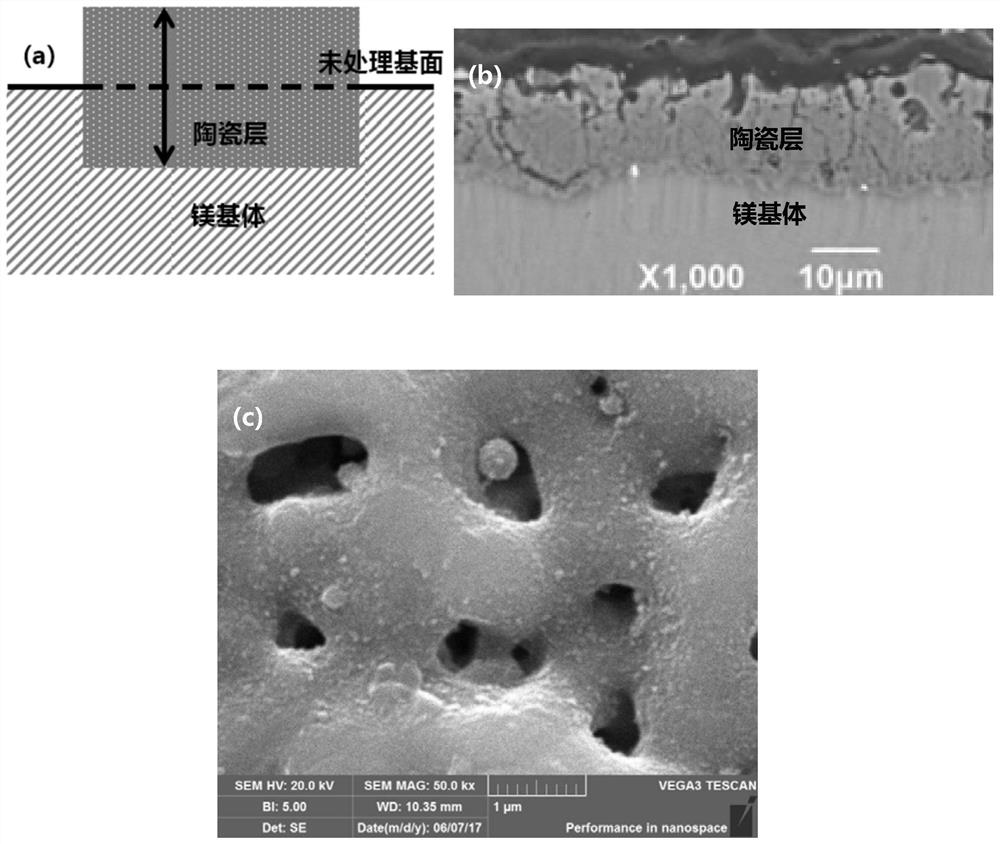

Image

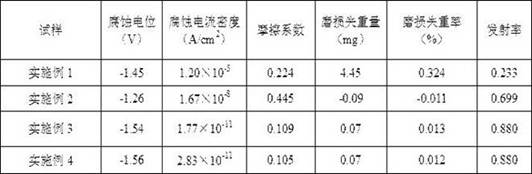

Examples

Embodiment 1

[0048] Step 1. Degreasing the surface of the VW93 magnesium alloy: the degreasing solution is: sodium hydroxide 50g / L, sodium phosphate 4g / L, sodium carbonate 6g / L, sodium lauryl sulfate 2mg / L. The degreasing temperature is 60°C and the time is 4min. After the treatment, the water droplets on the surface of the workpiece continue for 10S without interruption.

[0049] Step 2, pickling: pickling solution is: trisodium phosphate 8g / L, ammonium sulfate 3g / L, sodium nitrate 6g / L, tartaric acid 15g / L, oxalic acid 8g / L. The temperature is 45°C, and the time is 1 min. After the pickling is completed, there is no pitting on the surface of the workpiece.

[0050] Step 3, surface adjustment: surface adjustment solution is: sodium tripolyphosphate 10g / L, sodium hydroxide 20g / L, triethanolamine 5ml / L, triton 6ml / L. The temperature is 80°C, and the time is 5 minutes. After the surface adjustment is completed, the surface of the workpiece is shiny and free of residual loose oxides.

[...

Embodiment 2

[0054] Step 1, degreasing the surface of the VW93 magnesium alloy, the degreasing solution is: sodium hydroxide 50g / L, sodium phosphate 4g / L, sodium carbonate 6g / L, sodium lauryl sulfate 2mg / L. The degreasing temperature is 60°C and the time is 4min. After the treatment, the water droplets on the surface of the workpiece continue for 10S without interruption.

[0055] Step 2, pickling, the pickling solution is: trisodium phosphate 8g / L, ammonium sulfate 3g / L, sodium nitrate 6g / L, tartaric acid 15g / L, oxalic acid 8g / L. The temperature is 45°C, and the time is 1 min. After the pickling is completed, there is no pitting on the surface of the workpiece.

[0056] Step 3, surface adjustment, the surface adjustment solution is: sodium tripolyphosphate 10g / L, sodium hydroxide 20g / L, triethanolamine 5ml / L, triton 6ml / L. The temperature is 80°C, and the time is 5 minutes. After the surface adjustment is completed, the surface of the workpiece is shiny and free of residual loose oxid...

Embodiment 3

[0063] Step 1, degreasing the surface of the VW93 magnesium alloy, the degreasing solution is: sodium hydroxide 50g / L, sodium phosphate 4g / L, sodium carbonate 6g / L, sodium lauryl sulfate 2mg / L. The degreasing temperature is 60°C and the time is 4min. After the treatment, the water droplets on the surface of the workpiece continue for 10S without interruption.

[0064] Step 2, pickling, the pickling solution is: trisodium phosphate 8g / L, ammonium sulfate 3g / L, sodium nitrate 6g / L, tartaric acid 15g / L, oxalic acid 8g / L. The temperature is 45°C, and the time is 1 min. After the pickling is completed, there is no pitting on the surface of the workpiece.

[0065] Step 3, surface adjustment, the surface adjustment solution is: sodium tripolyphosphate 10g / L, sodium hydroxide 20g / L, triethanolamine 5ml / L, triton 6ml / L. The temperature is 80°C, and the time is 5 minutes. After the surface adjustment is completed, the surface of the workpiece is shiny and free of residual loose oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com