Stretching forming process for stainless steel elliptical-table-shaped ice bucket

A stretching forming and elliptical table technology, applied in the field of mechanical forming processing technology, can solve the problems of uneven welding, not easy to clean, low work efficiency, etc., to achieve smooth surface of the barrel wall, easy cleaning and cleaning, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

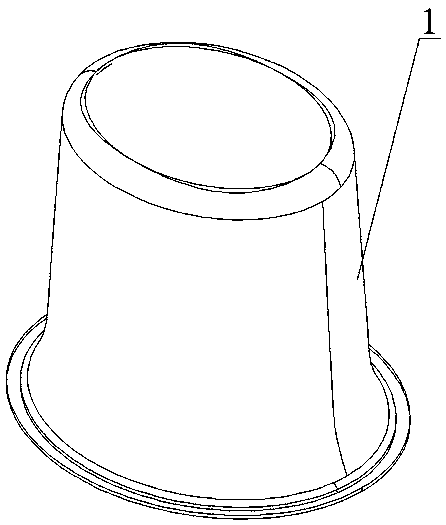

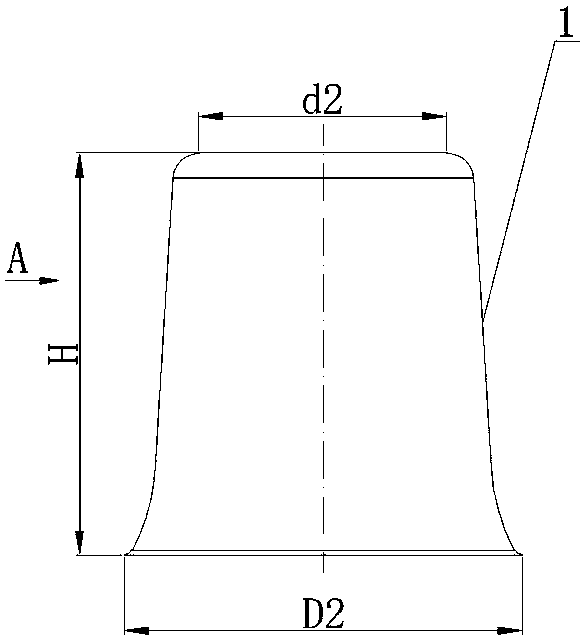

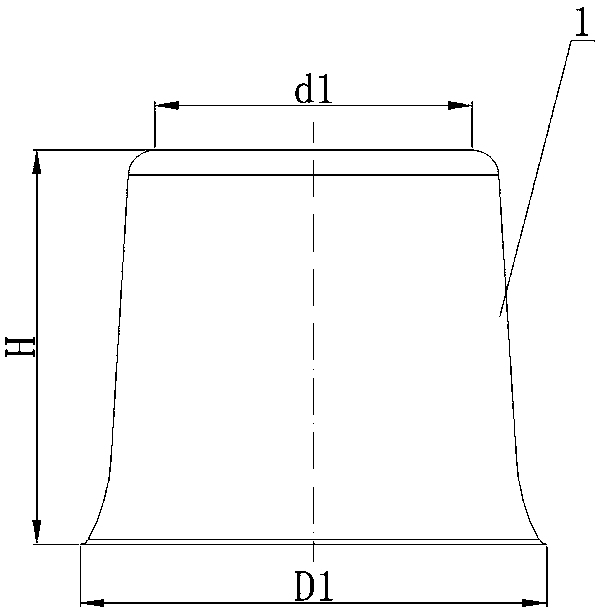

[0043] In this embodiment, the stainless steel sheet used is a 304 stainless steel sheet with a thickness of 1mm and a diameter of 200mm, and the final processing is as follows: figure 1 , figure 2 , image 3 As shown in the elliptical table-shaped ice bucket 1, the height H from the mouth of the elliptical table-shaped ice bucket 1 to the bottom of the bucket is 130 mm, the major axis D1 of the bucket mouth is 154 mm, the minor axis D2 is 130 mm, and the major axis d1 of the elliptical bucket bottom is is 105mm, and the minor axis d2 is 80mm. Its molding steps are as follows:

[0044] (1) First stretch:

[0045] The structure of the first stretching die used in the first stretching is as follows Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the first drawing die includes: a first die 21, a first p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com