Light degradation PE membrane and preparation method thereof

A photodegradation and photosensitive technology, applied in the field of photodegradation PE film and its preparation, can solve the problems of limited degradation speed, high production cost and high price, and achieve the effect of rapid degradation, favorable growth and complete degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

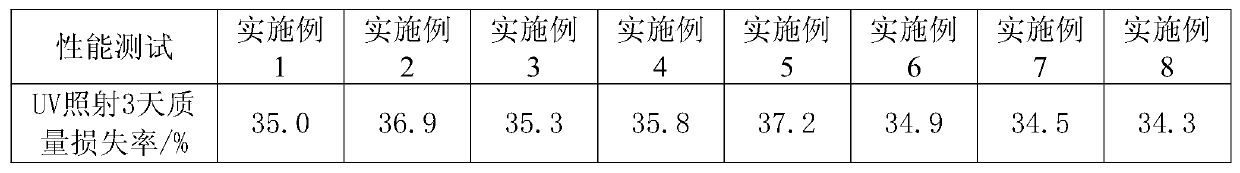

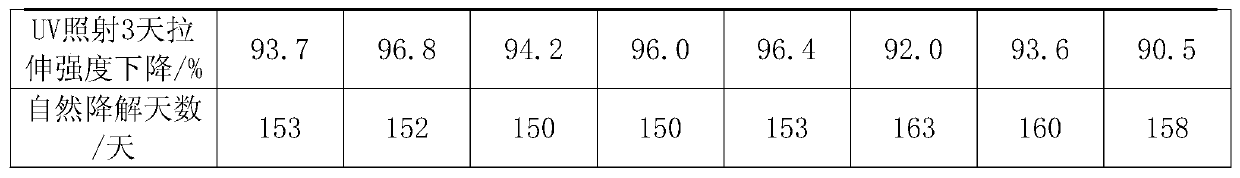

Examples

Embodiment 1

[0025] Prepare photodegradable PE film, comprise the following steps: take raw material according to table 1, wherein photosensitive masterbatch is composed as follows: 1wt% diatomite (particle size is 100nm-500nm), 20wt% iron stearate and 79wt% polyvinyl alcohol ( The relative molecular mass is 130,000-140,000, and the density is 1.28-1.30g / cm 3 ).

[0026] The raw materials are put into a single-layer film blowing machine, extruded by a screw at 160°C, blown in a mold at 168°C, cooled, pulled by a wheel, trimmed, wound and packaged to obtain the photodegradable PE film.

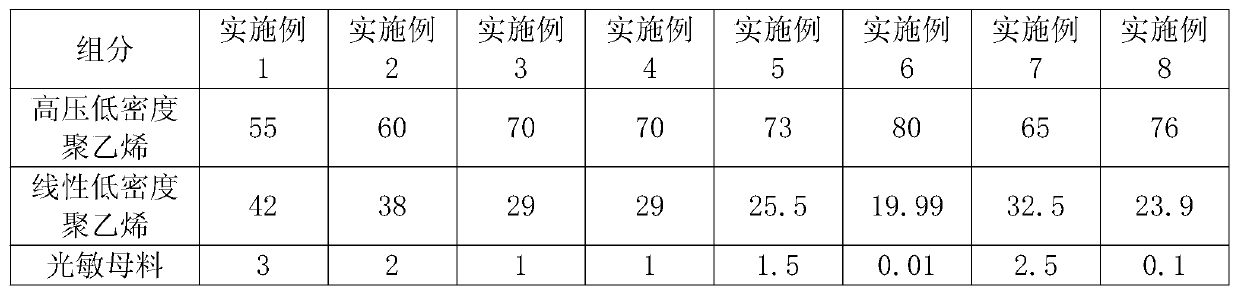

[0027] Table 1 raw material consumption table / wt%

[0028]

Embodiment 2

[0030] Prepare photodegradable PE film, comprise the following steps: take raw material according to table 1, wherein photosensitive masterbatch is composed as follows: 2wt% diatomite (particle size is 100nm-500nm), 20wt% iron stearate and 78wt% polyvinyl alcohol ( The relative molecular mass is 130,000-140,000, and the density is 1.28-1.30g / cm 3 ).

[0031] Put each raw material into a single-layer blown film machine, extrude through a screw at 150°C, inflate in a grinding tool at 168°C, cool, roll, trim, wind and pack to obtain the photodegradable PE film.

Embodiment 3

[0033] Prepare photodegradable PE film, comprise the following steps: take raw material according to table 1, wherein photosensitive masterbatch is composed as follows: 2wt% diatomite (particle size is 100nm-500nm), 20wt% zinc stearate and 78wt% polyvinyl alcohol ( The relative molecular mass is 130,000-140,000, and the density is 1.28-1.30g / cm 3 ).

[0034] Put each raw material into a single-layer blown film machine, extrude through a screw at 155°C, inflate in a grinding tool at 170°C, cool, roll, trim, wind and pack to obtain the photodegradable PE film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com