Stirring type soil drying device

A drying device and stirring technology, applied in non-progressive dryers, heating devices, drying solid materials, etc., can solve the problems of slow drying speed, insufficient heat transfer, low drying efficiency, etc., to achieve convenient disassembly and assembly, avoid Effect of heat loss and improved drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

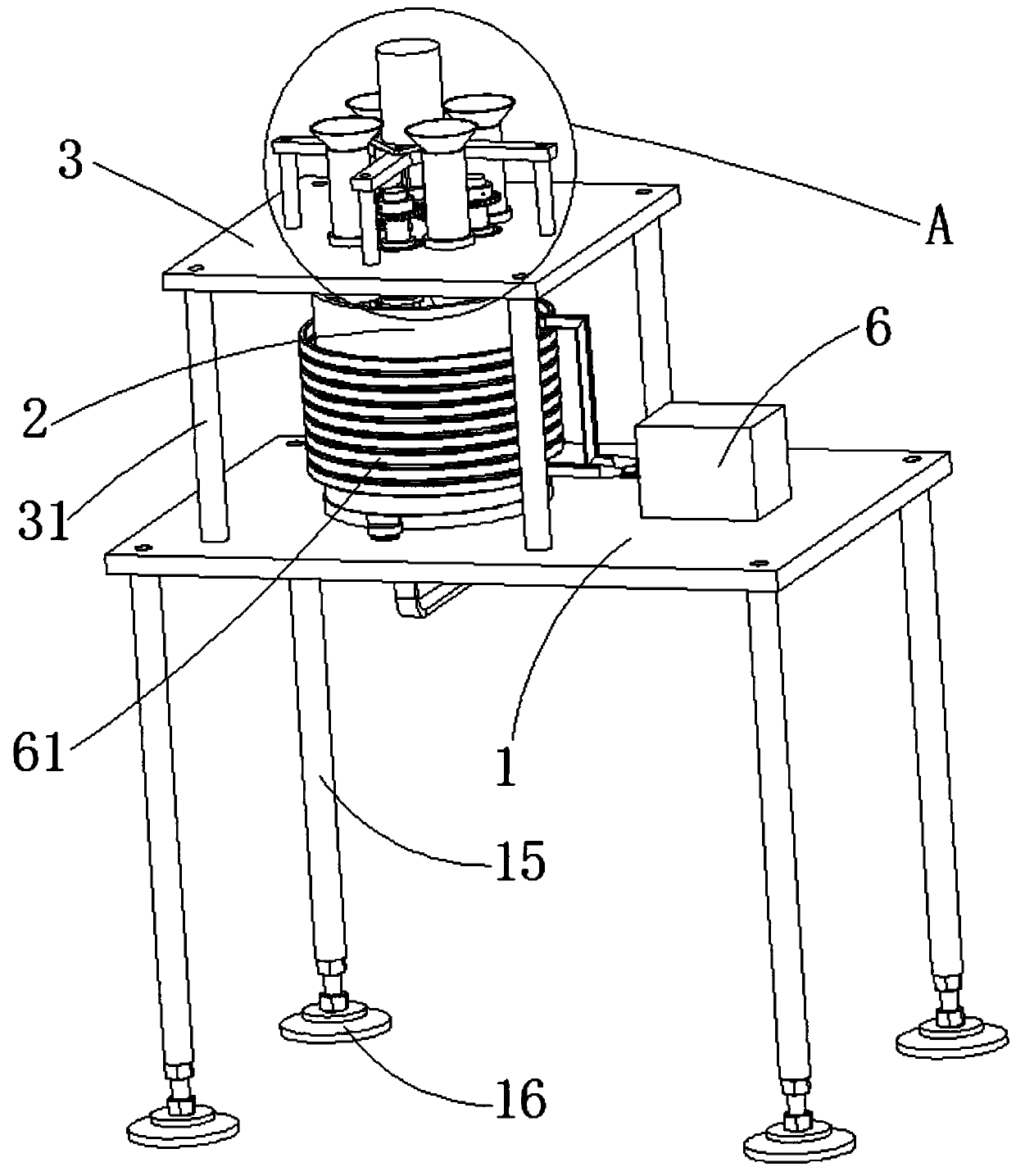

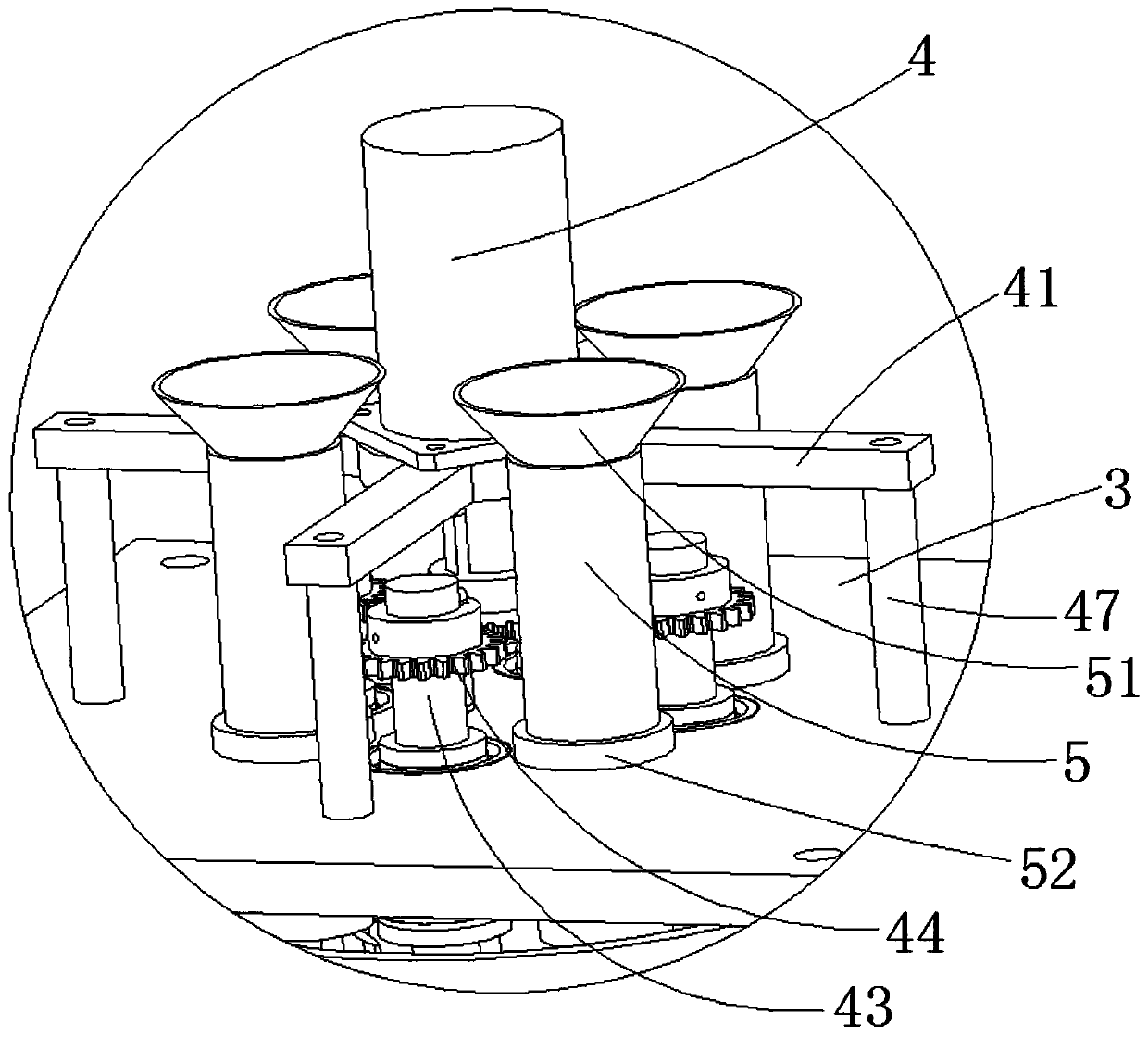

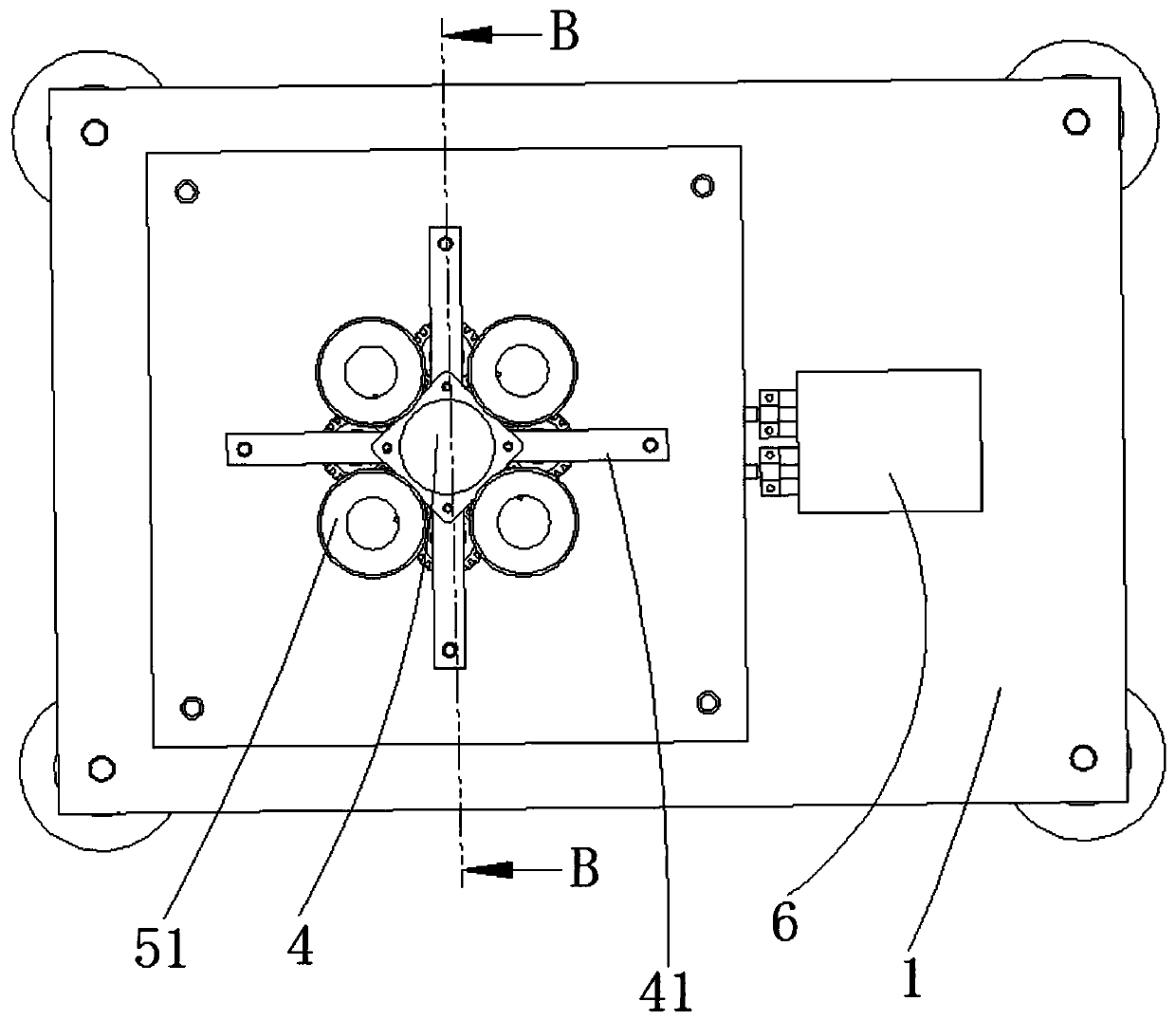

[0033] Such as Figure 1 to Figure 14 As shown, a stirring type soil drying device includes a platen 1, the platen 1 is a square structure, a platen support rod jack 14 is provided at the four corners of the platen 1, and the platen support rod jack 14 Connect the platen support bar 15 on the top, and the bottom of the platen support bar 15 is threadedly connected with footings 16, and is screwed in and out by the screw of the footings 16 to adjust the height and the contour balance of the four footings 16.

[0034] A drum 2 with an open upper end and soil contained inside is installed on the deck 1, and a drum perforation 11 for the drum 2 to pass is provided on the deck 1, and the diameter of the drum perforation 11 is larger than that of the drum 2. The outer wall diameter (because also will adorn a heat-insulating sleeve 8 between the two), drum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap