Monomolecular intumescent flame retardant MPPR and MPPR/POSS composite synergistic halogen-free flame-retardant polypropylene composite material

An intumescent flame retardant, flame retardant polypropylene technology, applied in organic chemistry and other directions, can solve the problems of inability to achieve flame retardant effect, affect flame retardant performance, high addition amount, etc., to shorten the time required for preparation, achieve resistance The effect of improving the flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

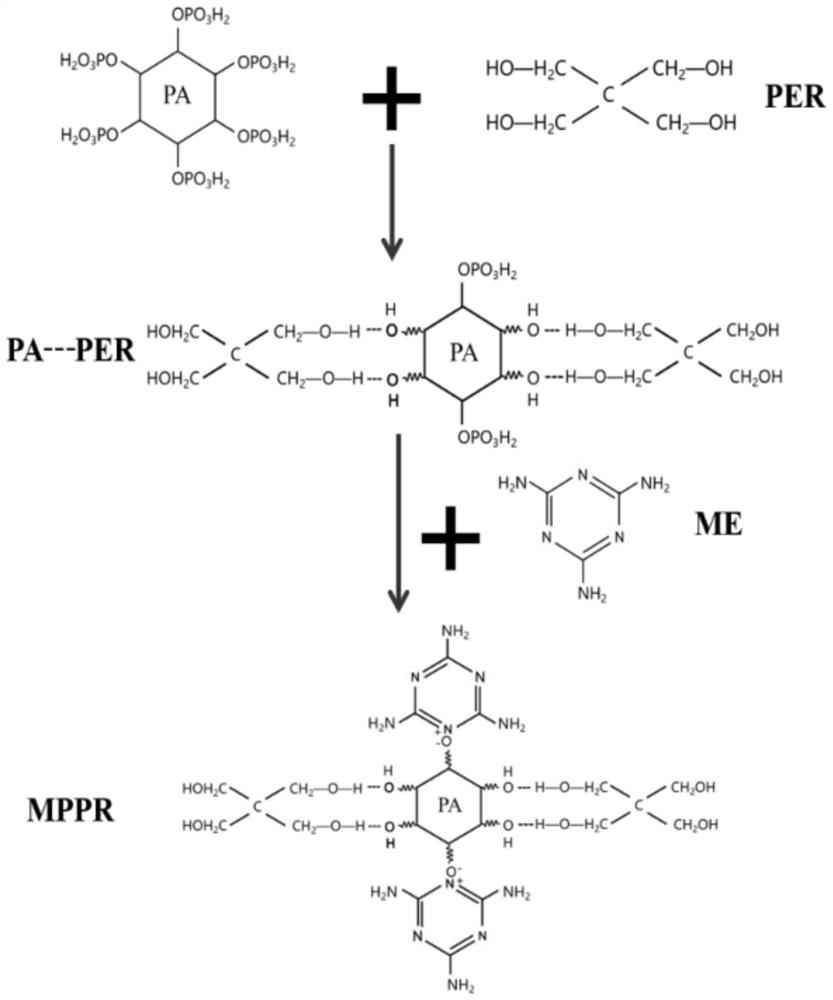

[0134] The preparation method of the monomolecular intumescent flame retardant MPPR of this synthesis example comprises the following steps:

[0135] (1) Prepare phytic acid solution with 0.05mol phytic acid and 200ml deionized water;

[0136] (2) Add pentaerythritol to the phytic acid solution obtained in step (1), and stir and react at 95-100°C for 1 hour; then add melamine, and continue to stir and react at 95-100°C for 0.5h to obtain yellow, clear and transparent mixture;

[0137] (3) Cool the mixed solution obtained in step (2) and dry it to a constant weight to obtain a white block monomolecular intumescent flame retardant MPPR.

[0138] Wherein, the molar ratio of phytic acid, pentaerythritol and melamine used in the above preparation method is 1:2.5:2.

Synthetic example 2

[0140] The preparation method of the monomolecular intumescent flame retardant MPPR of this synthesis example comprises the following steps:

[0141] (1) Prepare phytic acid solution with 0.1mol phytic acid and 600ml deionized water;

[0142] (2) Add dipentaerythritol to the phytic acid solution obtained in step (1), and stir and react at 95-100°C for 1.5h; then add melamine, and continue to stir and react at 95-100°C for 1h to obtain clear and transparent yellow mixed solution;

[0143] (3) Cool the mixed solution obtained in step (2) and dry it to a constant weight to obtain a white block monomolecular intumescent flame retardant MPPR.

[0144] Wherein, the molar ratio of phytic acid, dipentaerythritol and melamine used in the above preparation method is 1:2.4:2.1.

Synthetic example 3

[0146] The preparation method of the monomolecular intumescent flame retardant MPPR of this synthesis example comprises the following steps:

[0147] (1) Prepare phytic acid solution with 0.15mol phytic acid and 1000ml deionized water;

[0148] (2) Add tripentaerythritol to the phytic acid solution obtained in step (1), and stir and react at 95-100°C for 2 hours; then add melamine, and continue to stir and react at 95-100°C for 1 hour to obtain yellow, clear and transparent mixture;

[0149] (3) Cool the mixed solution obtained in step (2) and dry it to a constant weight to obtain a white block monomolecular intumescent flame retardant MPPR.

[0150] Wherein, the molar ratio of phytic acid, tripentaerythritol and melamine used in the above preparation method is 1:2.6:1.9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com