Two-core wire embedding structure for storage package of calibration parameters of vibrating wire sensors

A technology for vibrating wire sensors and calibration parameters, which is applied in the field of connection structures for obtaining sensing and transmitting signals of vibrating wire sensors, can solve problems comparable to those of a few meters, and the longest is no more than 20 meters. The solution is difficult to implement and the product is reliable. Reduced performance and other issues, to achieve the effect of simple composition and structure, long-distance reliability, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical content of this patent application will be described below through specific examples, but the protection scope of this patent application is not limited to the examples because of the specific description.

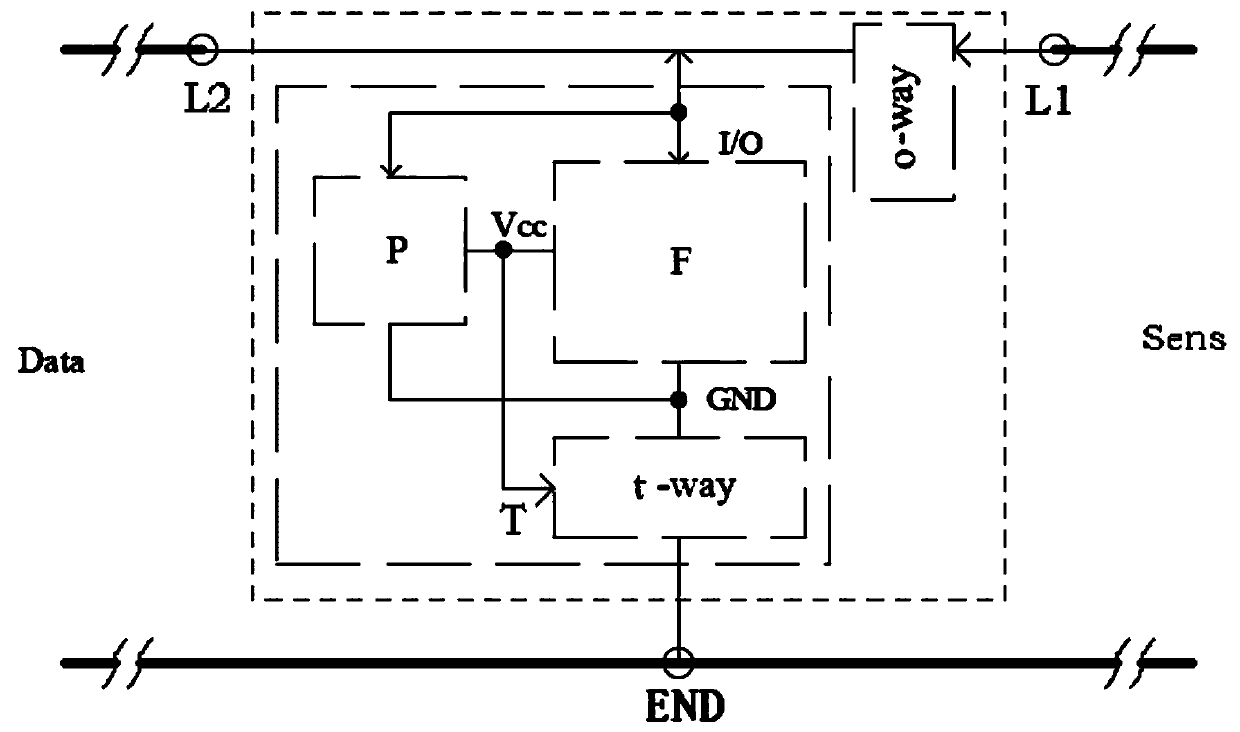

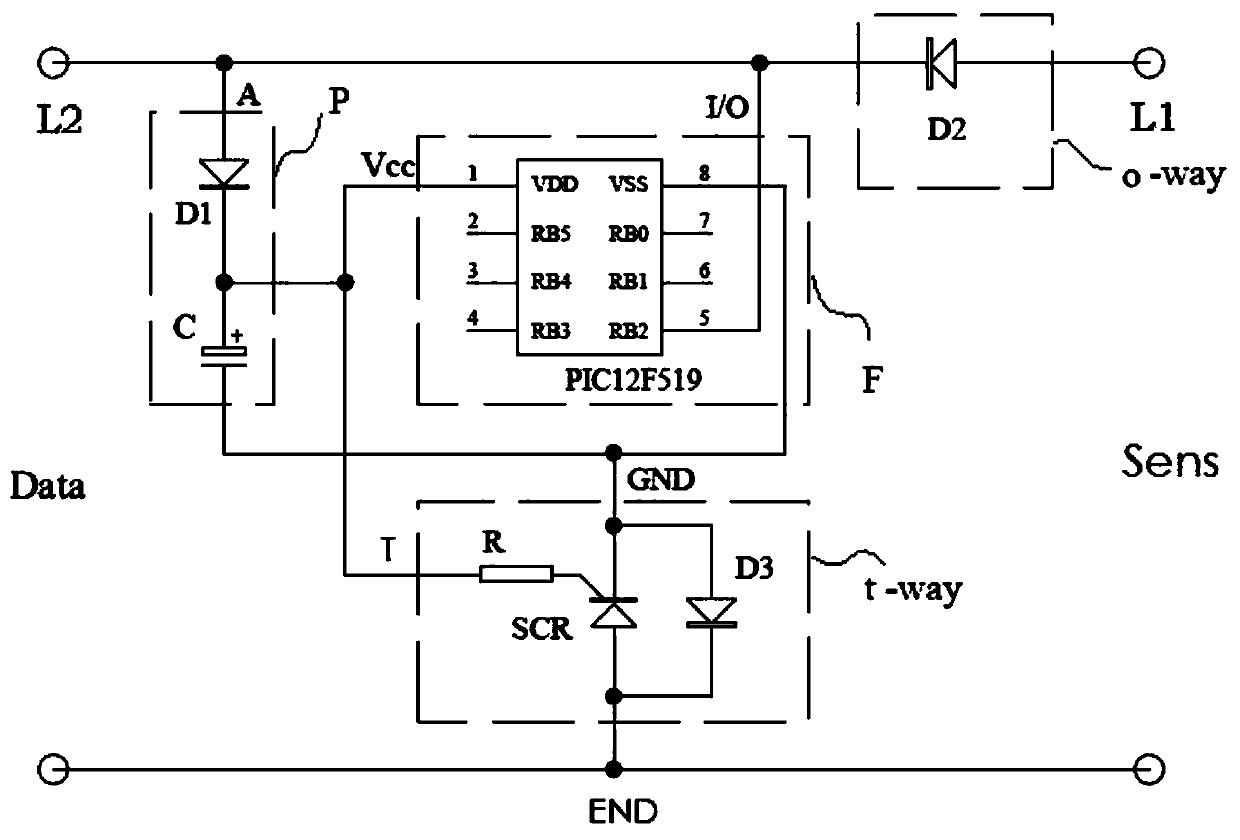

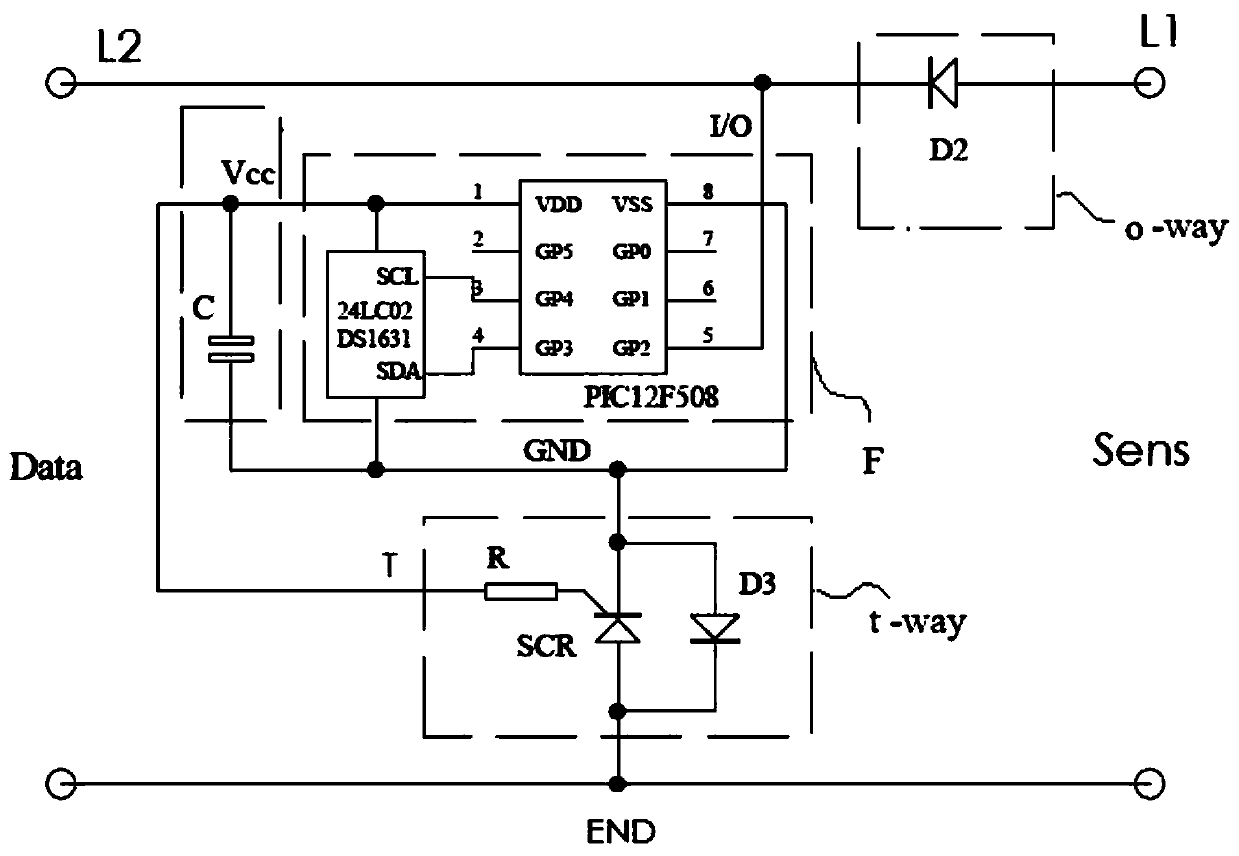

[0014] The calibration parameter storage of the vibrating wire sensor includes a two-core wire embedded structure, and its composition includes a storage unit for storing the calibration parameters of the connected vibrating wire sensor, such as figure 1 As shown in the dotted box, the storage unit is connected to the vibrating wire sensor through the measurement port Sens, and connected to the external measurement and control device through the communication port data.

[0015] The storage unit includes a storage circuit F, a power supply circuit P and a bidirectional switch circuit t-way, wherein the storage circuit F can be formed by selecting a storage chip, or can be selected such as Figure 5 The memory chip DS2430A of the one-line bus system is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com