An intelligent splicing and assembly method for aspherical complex curved surface workpieces

A technology of complex curved surfaces and assembly methods, applied in installation, measurement devices, optical components, etc., can solve the problems of inability to provide real-time feedback correction of assembly errors, low efficiency, etc., so as to reduce assembly adjustment time, reduce assembly errors, and simplify assembly. effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention are described below through examples. Examples are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention. Some non-essential improvements and adjustments made by those skilled in the art according to the content of the present invention also belong to the protection scope of the present invention.

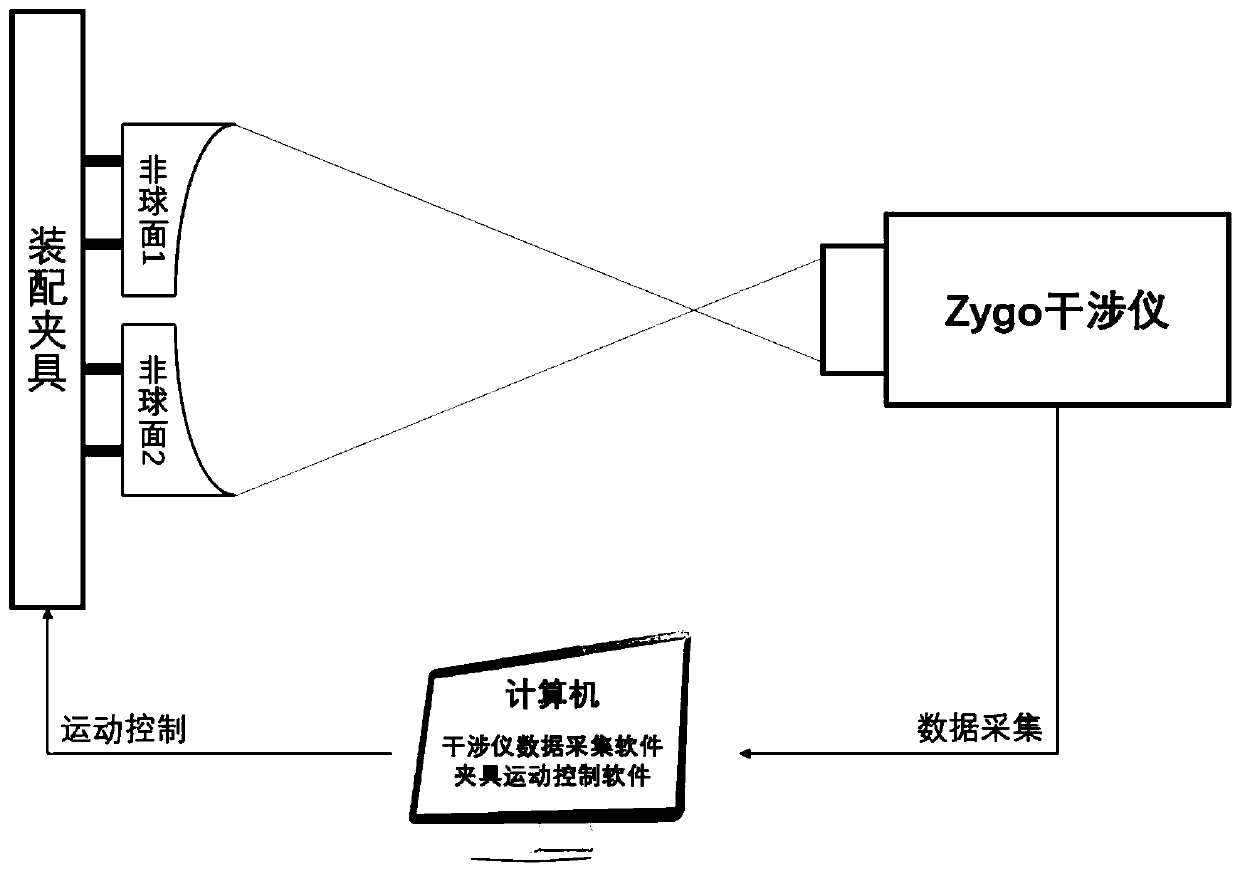

[0023] An intelligent splicing and assembling method for workpieces with complex aspherical surfaces, comprising the following steps:

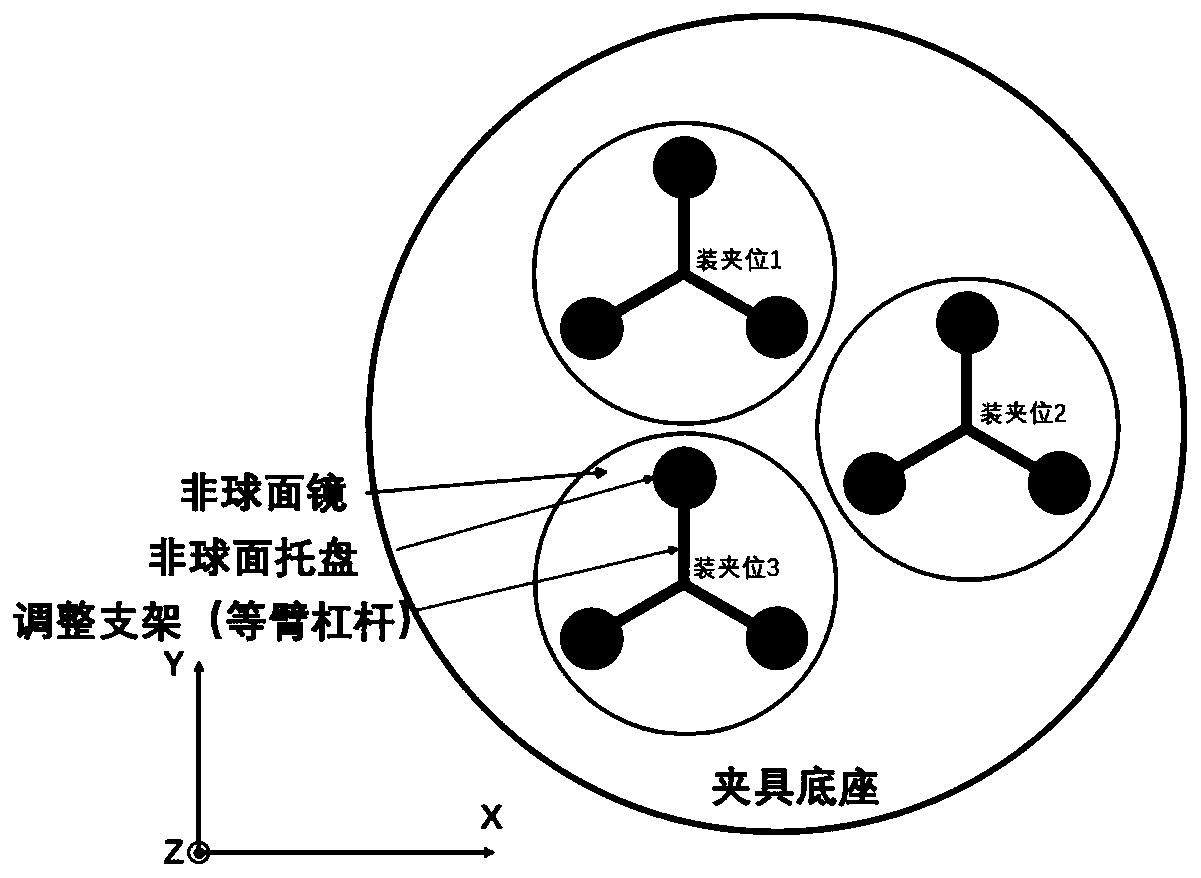

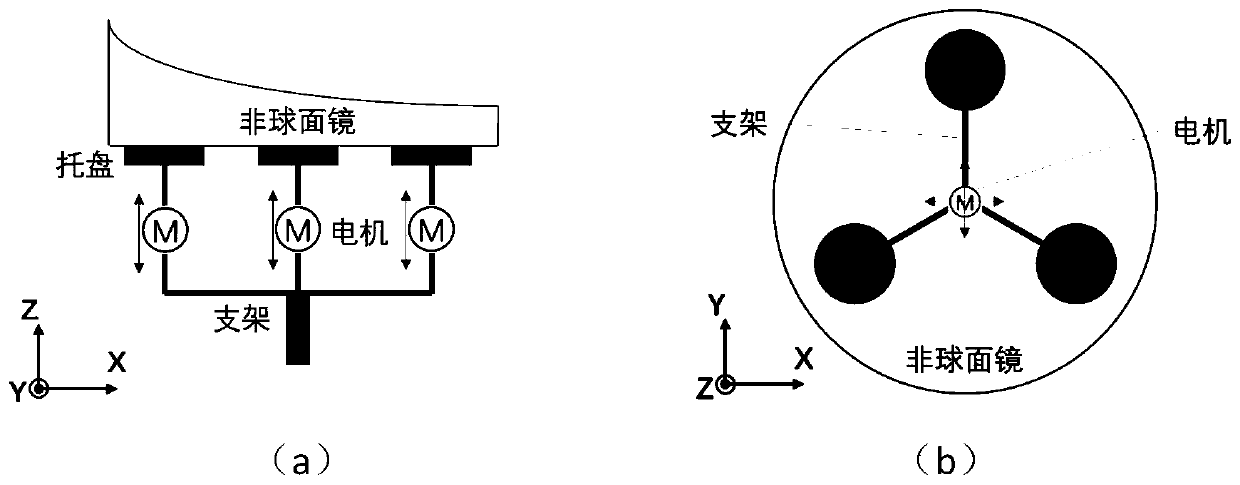

[0024] (1) First design and manufacture a multi-degree-of-freedom adjustable aspheric splicing assembly fixture. The fixture is driven by a high-precision motor, has several clamping positions, and adopts multi-point support. According to different calibers, each aspheric mirror is made of 3-6 pallets are supported as a group, and each group of support is controlled by an equal arm lever, and adopts a balanced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com