Threshold voltage drift detection method and threshold voltage drift detection device

A technology of threshold voltage drift and detection method, which is applied to instruments, static indicators, etc., and can solve problems such as inability to test the stability of array substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

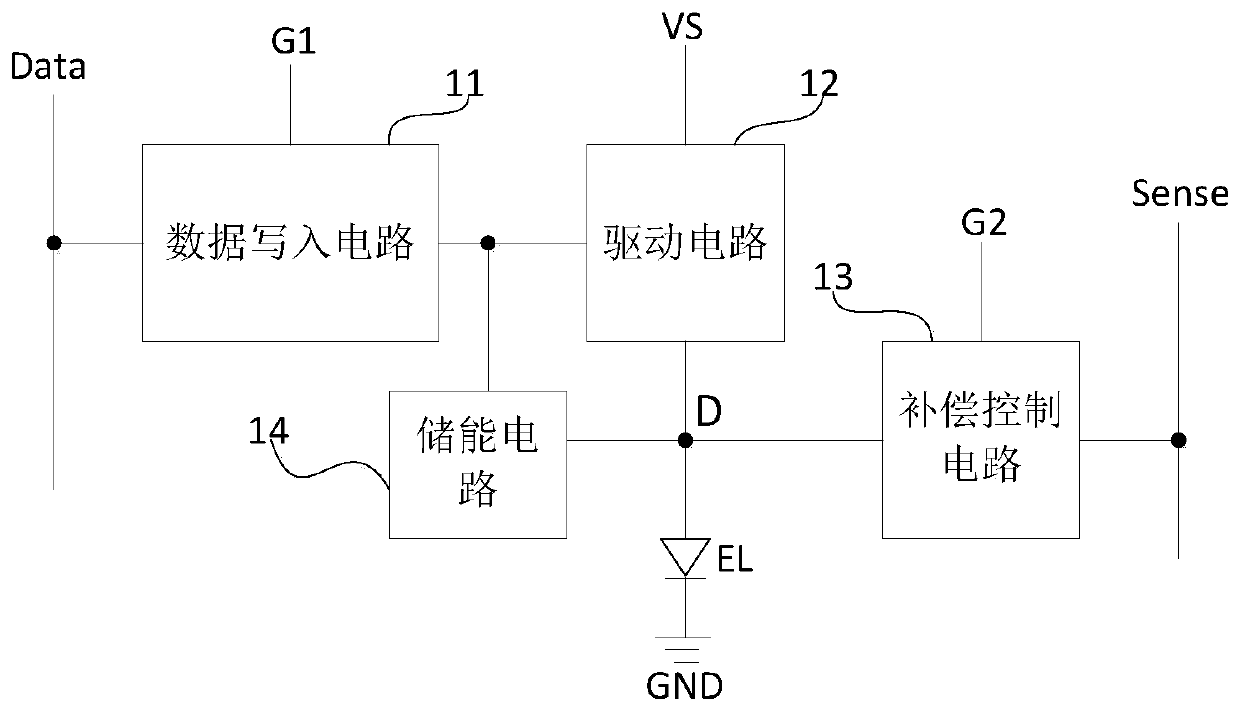

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

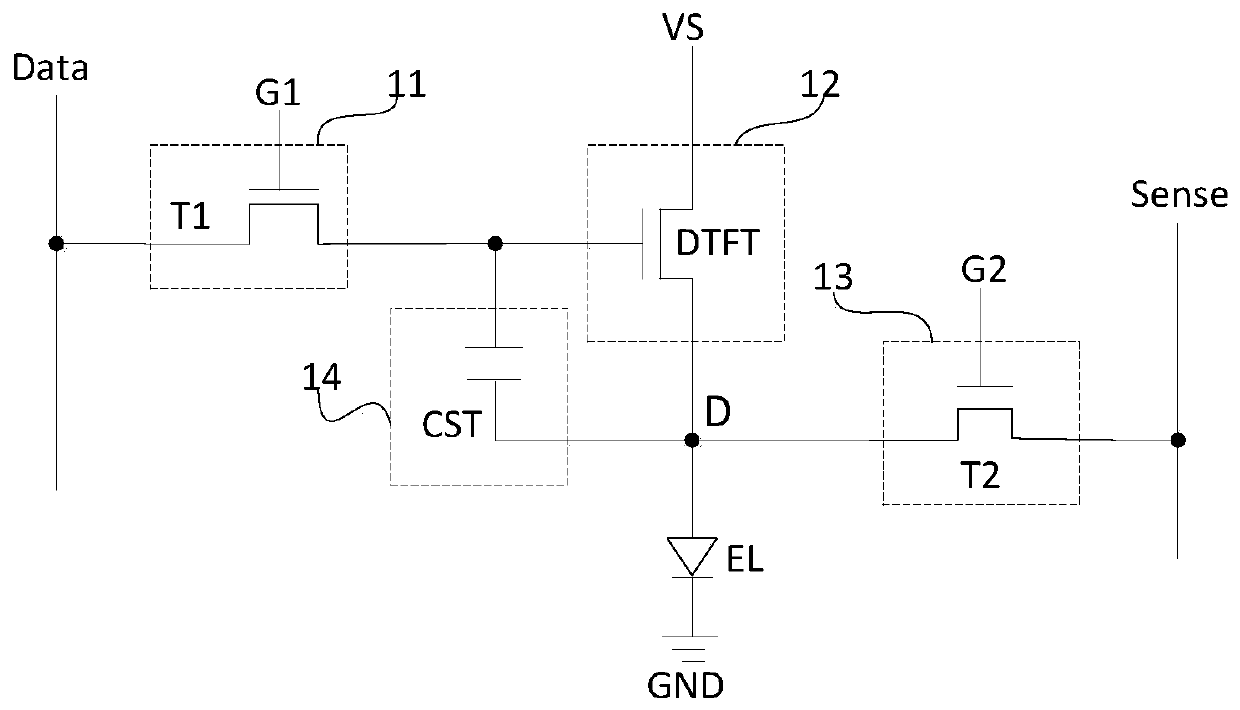

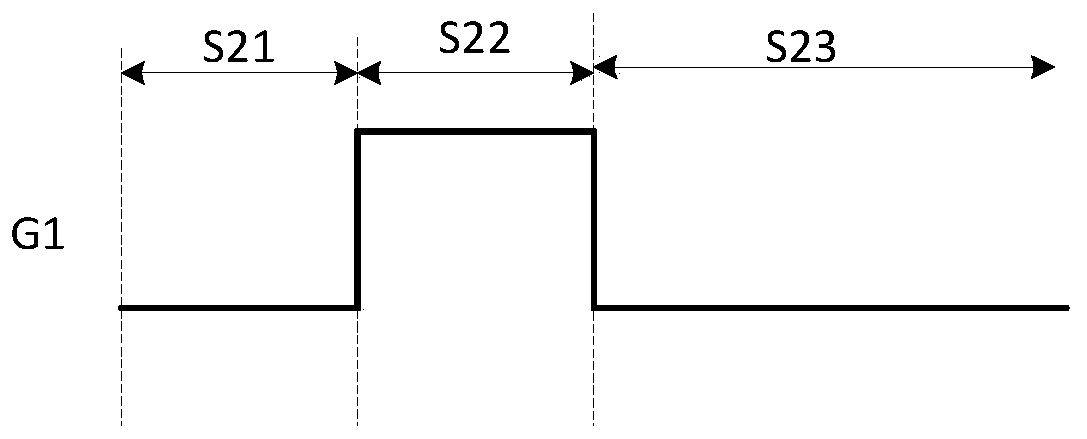

[0127] According to a specific implementation manner, the control pole of the driving transistor is the control terminal of the driving circuit, the first pole of the driving transistor is electrically connected to the power supply voltage line, and the second pole of the driving transistor is connected to the The detection node is electrically connected; the step of controlling a transistor included in the pixel driving circuit to be in a biased state during the setting phase may include:

[0128] In the set phase, a predetermined second data voltage is provided to the data line, and a third gate driving voltage signal is provided to the gate line, so that the data writing circuit controls to write the second data voltage writing into the control electrode of the driving transistor, and supplying a predetermined second power supply voltage to the power supply voltage line, so as to control the driving transistor to be in a bias state.

[0129] During specific implementation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com