Electric heating pad power cut-off device and method

A technology of cutting device and electric heating pad, which is applied to electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of complicated and boring users, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The configuration of the present invention will be described in detail below in conjunction with the accompanying drawings.

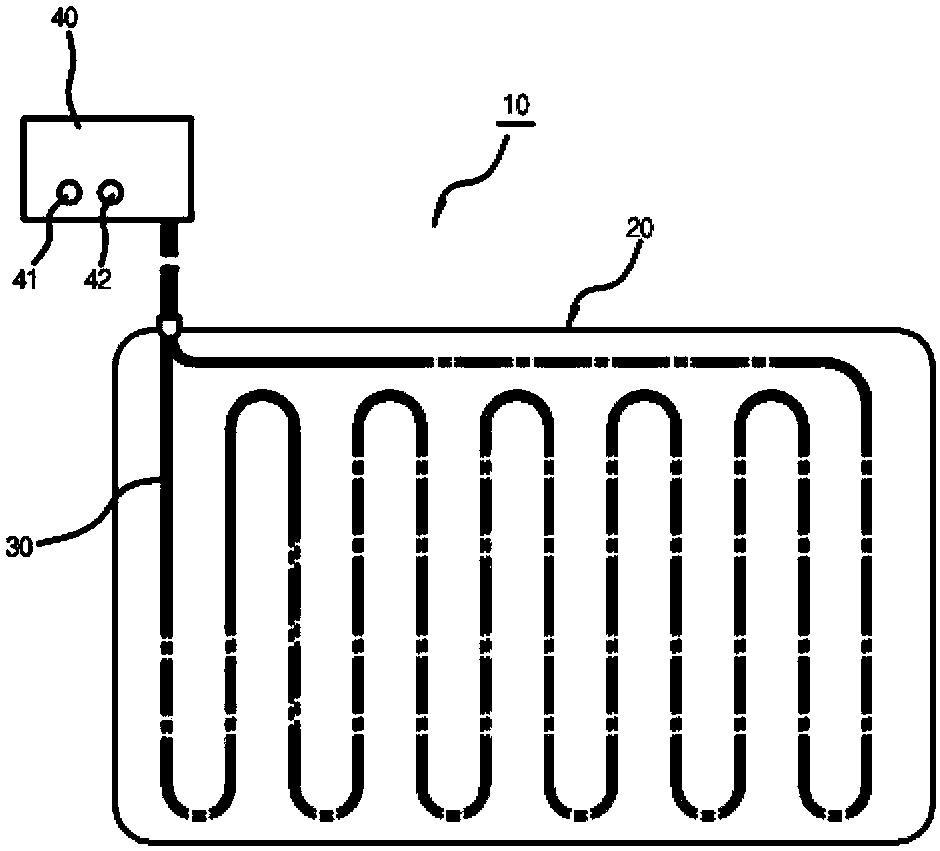

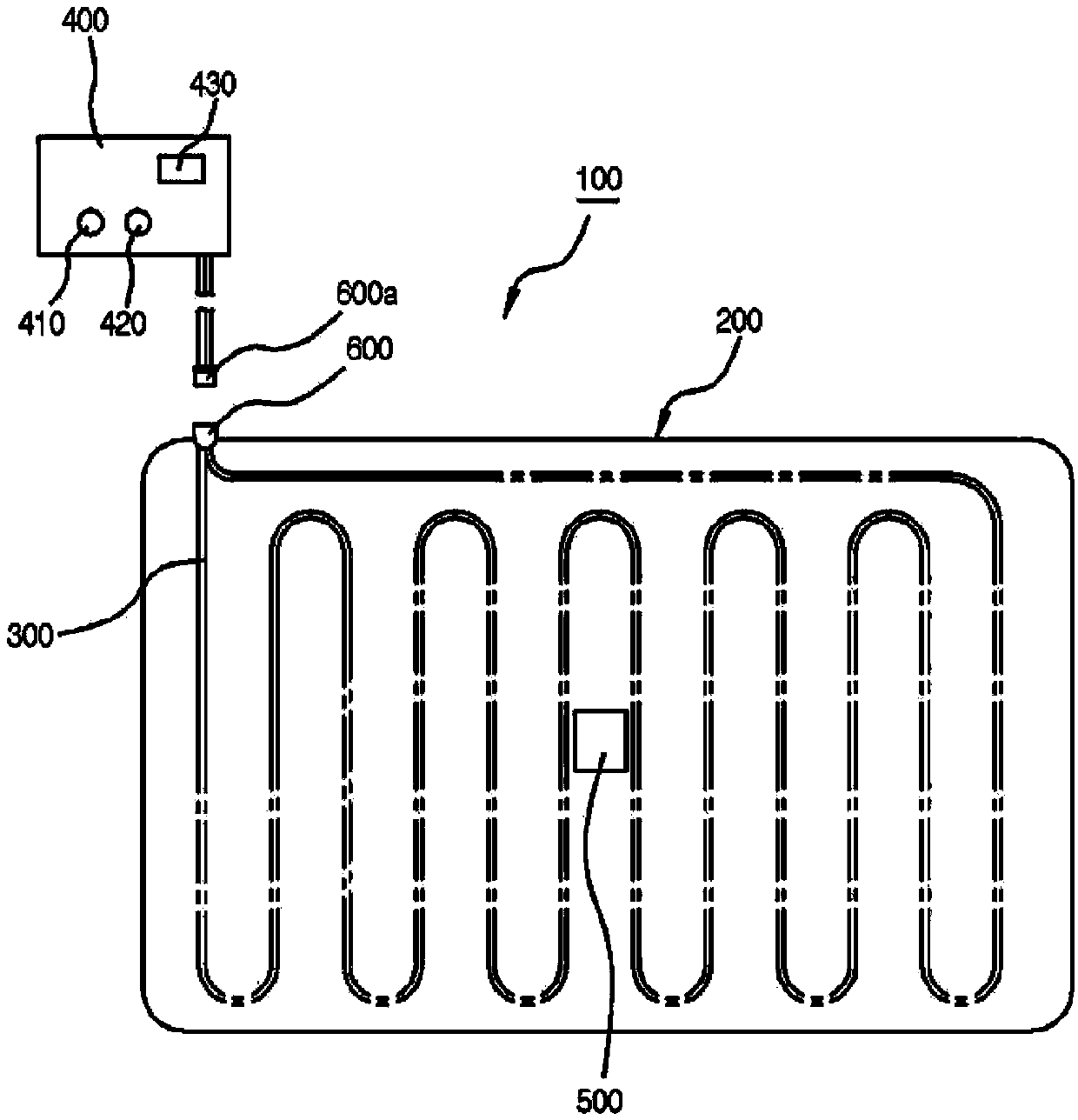

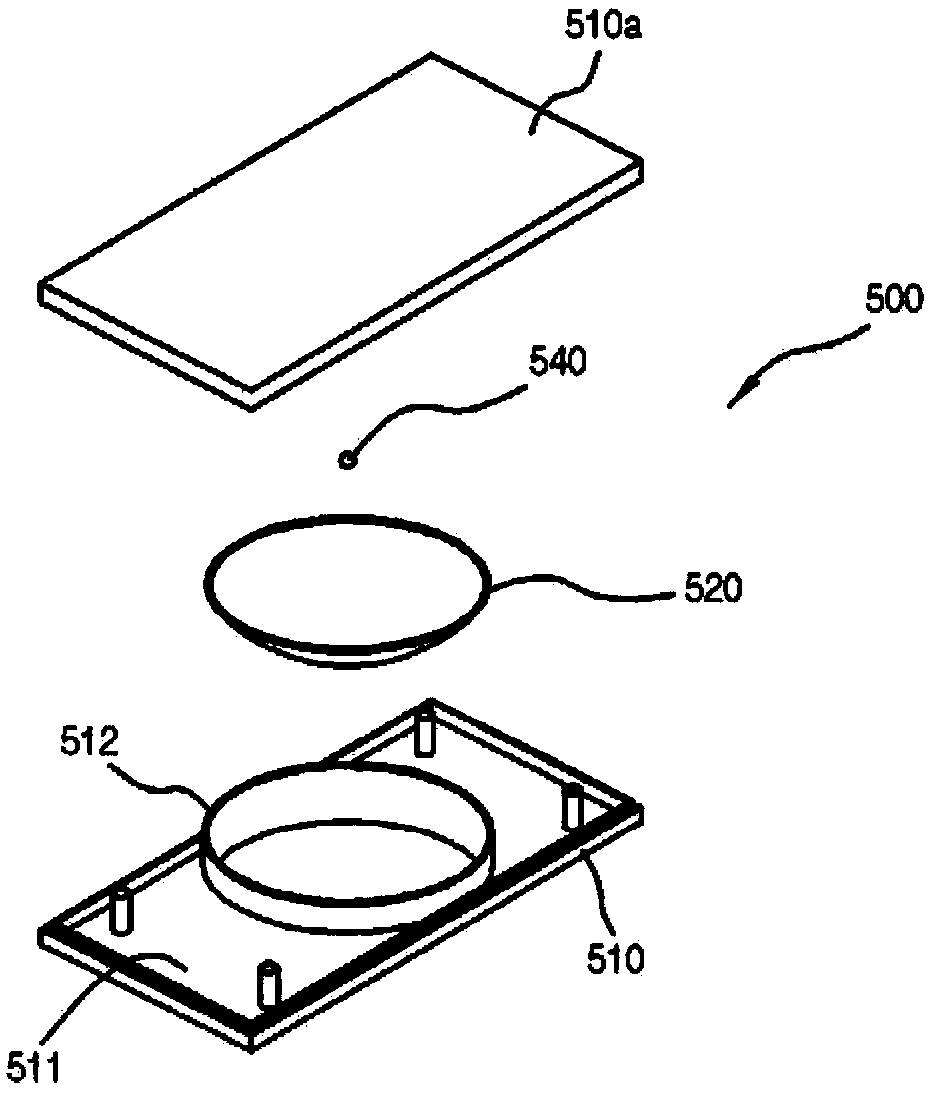

[0051] figure 2 It is an illustration showing the structure of a general heating pad. The heating pad 100 includes a mattress 200 with a size for a user to sit or lie on, a heating wire 300 buried inside the mattress, and a wire connected to the heating wire. In this state, the power regulator 400 and the sensing component 500 are turned on or off.

[0052] The mattress pad 200 includes a cushion part 210 having a predetermined thickness, and a cover part 220 placed on the upper and lower surfaces of the cushion part, and their outer peripheries can be decorated by tailoring.

[0053] At this time, the above-mentioned mattress can be made into various sizes such as single or double and extra large according to the purpose of use.

[0054] Moreover, the heating wire 300 is buried inside the mattress 200, and the end portions on both sides are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com