Electric heating insole and manufacturing method thereof

A production method and technology of electric heating pads, which are applied in the direction of insoles, footwear, clothing, etc., can solve the problems of insufficient sealing and easy damage of electric heating insoles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

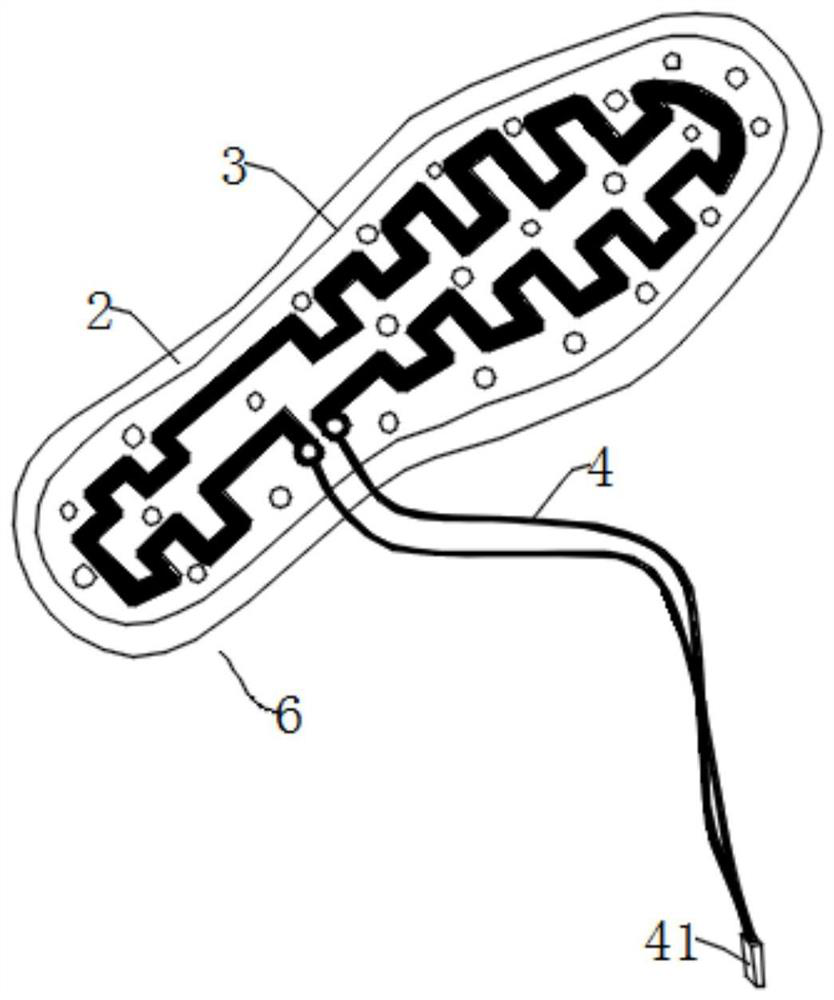

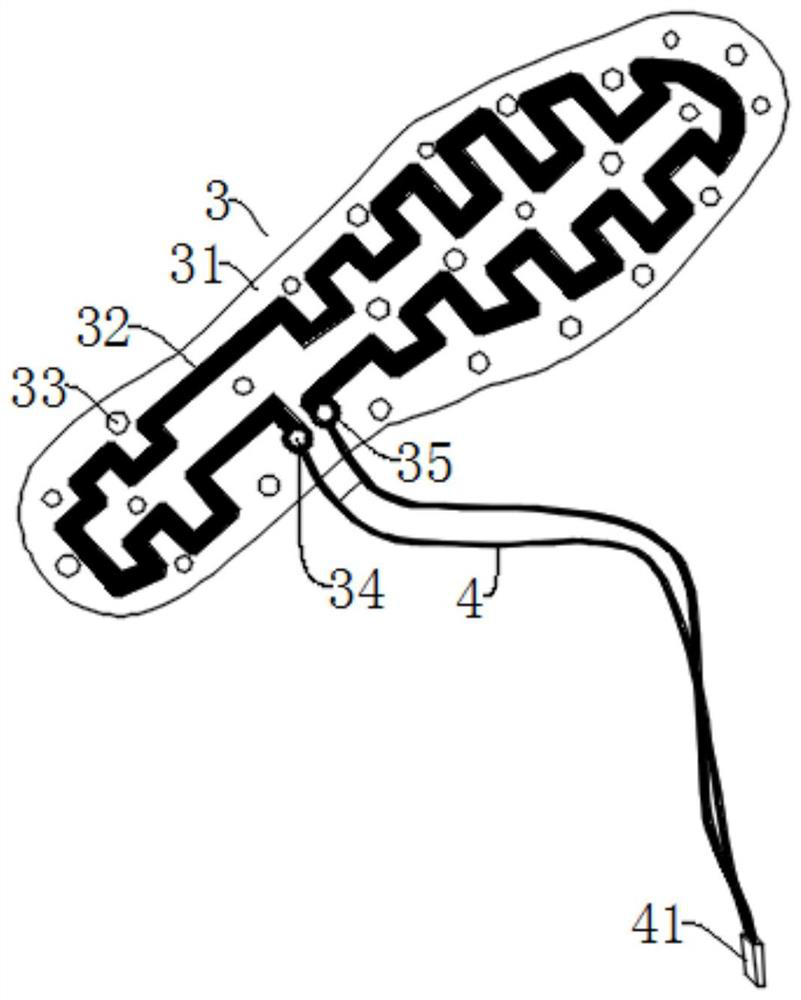

[0047] see figure 1 with figure 2 with Image 6 , figure 1 It is the schematic diagram of the structure of the electric heating insole; figure 2 It is the connection structure diagram of electric heating pad and electric wire; Image 6 It is a schematic diagram of the structure of the ankle brace.

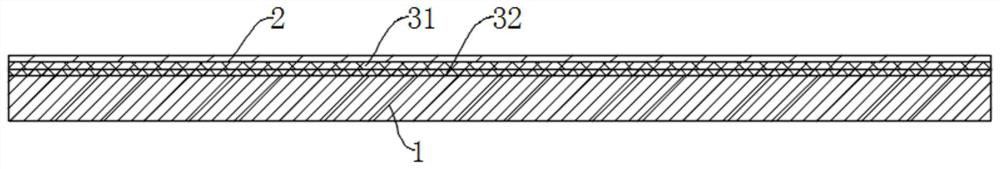

[0048] An electric heating insole, the electric heating insole consists of a cutting pad 2, an insulating film 31, an electric heating strip 32 and an insole 1 from top to bottom, the cutting pad 2 is cut from a polyurethane sheet, and the insulating film 31 is set as a polyester film. The insole 1 is formed by stirring and mixing isocyanate, combined polyether, negative ion powder, and trimerization catalyst raw materials into a polymerization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com