Self-heating flexitank

A container and self-heating technology, which is applied in packaging, transportation and packaging, transporting passenger cars, etc., can solve the problems of low energy utilization rate, inconvenient operation, and low heating efficiency, so as to improve energy utilization rate and solve inconvenience , the effect of high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

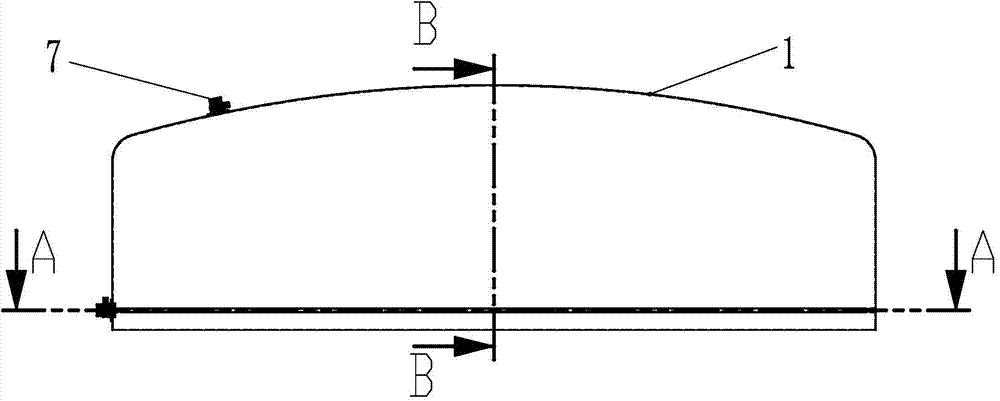

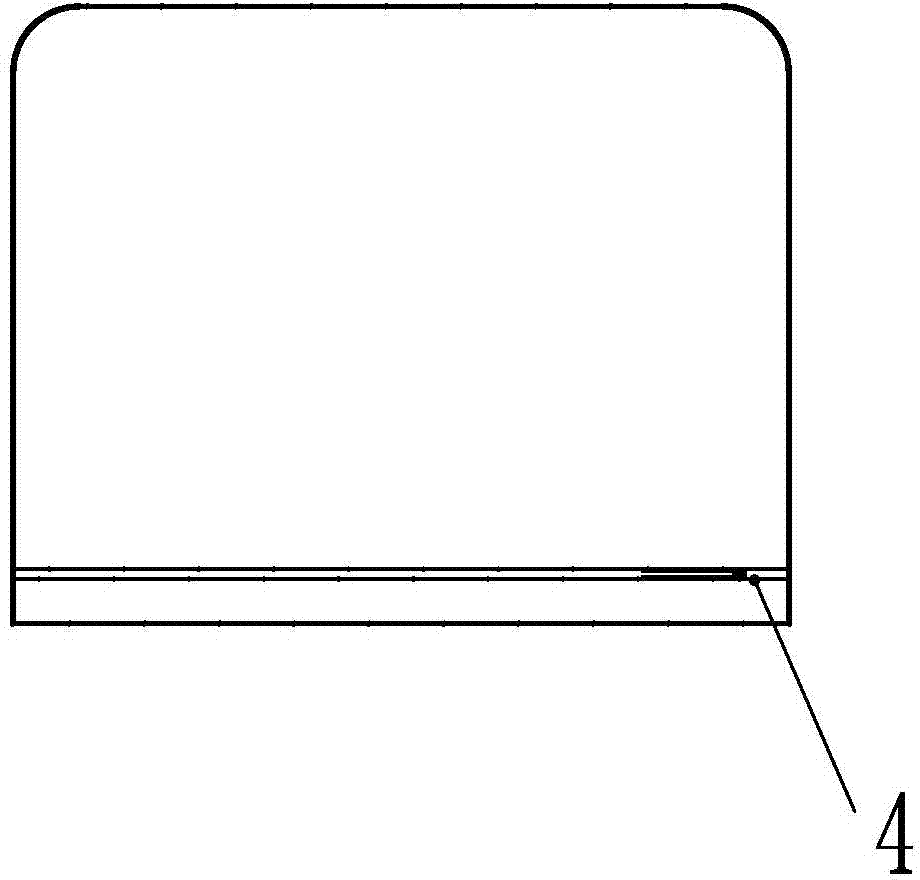

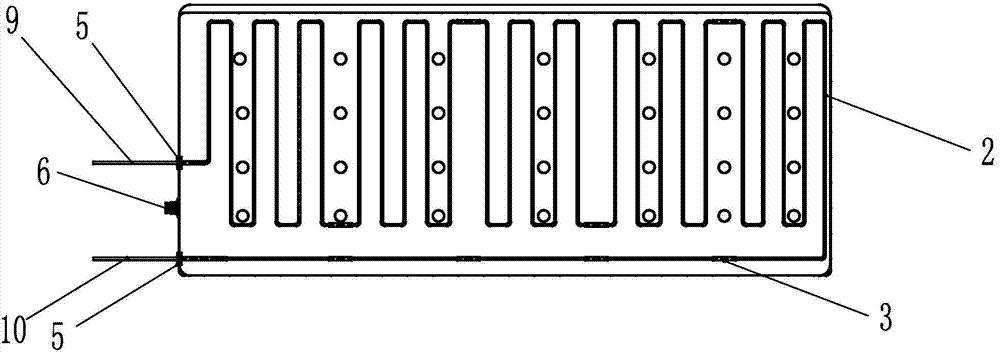

[0032] Such as Figure 1-4 As shown, a self-heating flexitank of the present invention includes a flexitank body 1, a waveform heating pipe 2, a heat-resistant hose 3, a heating system protective layer 4, a connecting flange between the heating system and the flexitank 5, wherein the corrugated heating pipe 2 is connected and sealed by a heat-resistant hose 3, and then the sealed-connected corrugated heating pipe 2 and heat-resistant hose 3 are arranged in the middle of the two-layer heating system protective layer 4 and fixed by heat sealing. as one.

[0033] In the self-heating flexitank of the present invention, the fixed waveform heating pipe 2, the heat-resistant hose 3, and the heating system protective layer 4 are connected together with the flexitank 1 through heat sealing, and the fixed waveform The heating pipe 2, the heat-resistant hose 3 and the heating system protection layer 4 are fixed inside the container flexitank body 1.

[0034] A self-heating flexitank ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com