Fine positioning cartilage forceps

A fine positioning and cartilage tweezers technology, applied in the field of medical devices, can solve problems such as affecting suturing operations, inconvenient suturing, and cartilage slipping, and achieve the effects of not being easily damaged and broken, easy to promote, and avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

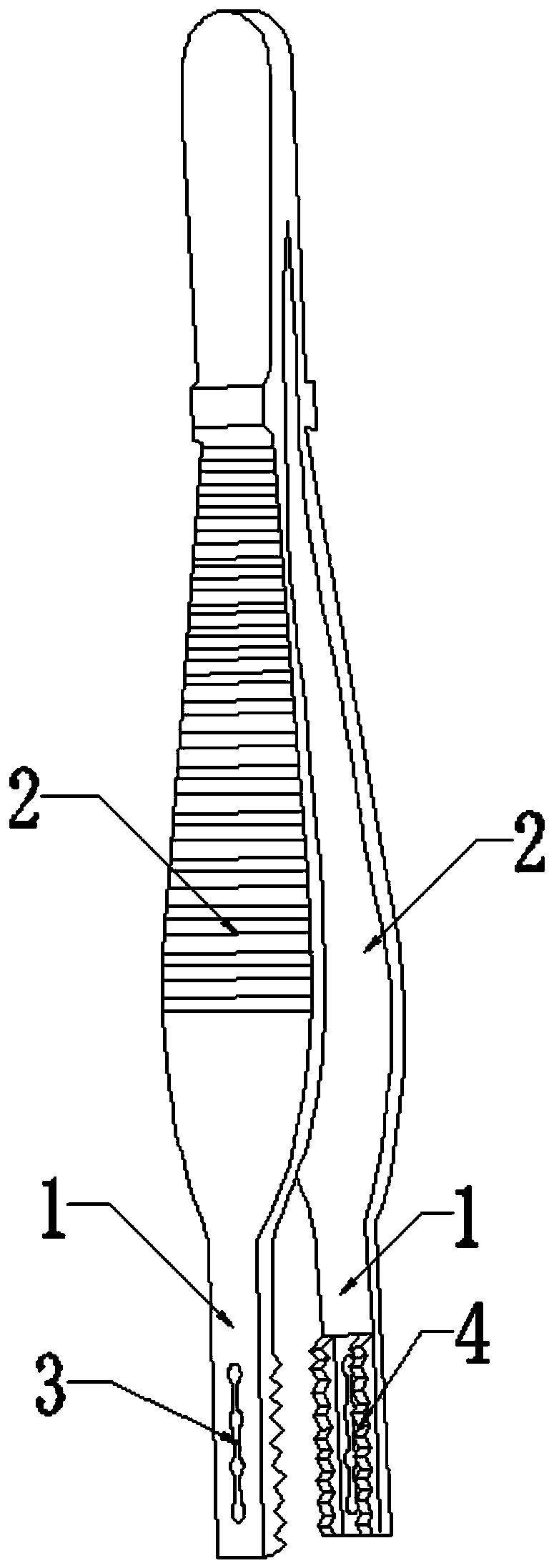

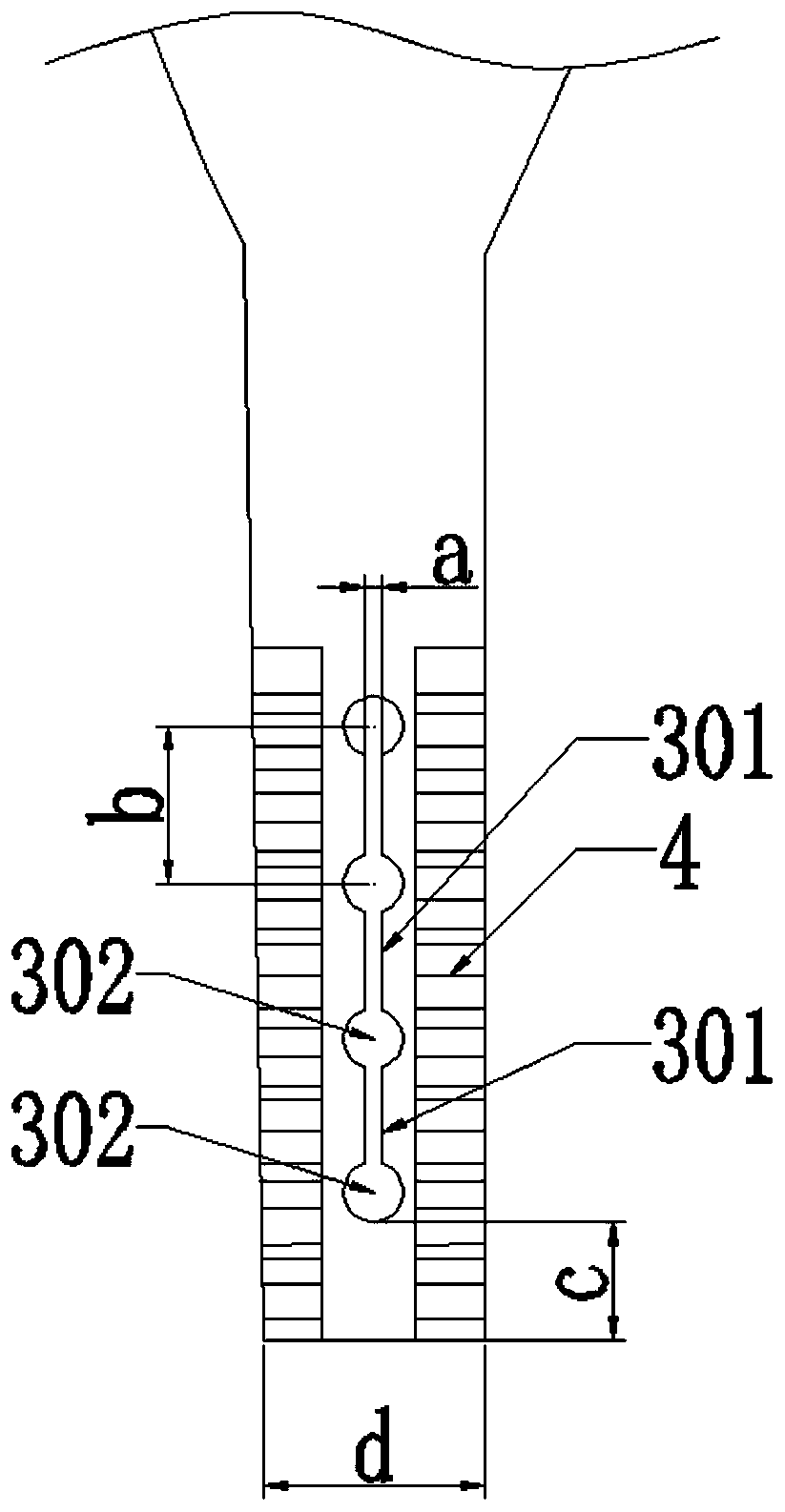

[0036] Such as figure 1 and figure 2 As shown, a fine positioning cartilage tweezers includes two clamping parts 1 and two handles 2, and the two clamping parts 1 and the two handles 2 are provided in one-to-one correspondence. One end is fixedly connected to one end of the corresponding handle 2 , the other ends of the two handles 2 are fixedly connected, the clamping part 1 has a suture through hole 3 , and the inner side of the clamping part 1 has an engaging part 4 .

[0037] Specifically, the inner side of the clamping part 1 refers to the opposite surface of the two clamping parts 1 .

[0038] Specifically, the clamping part 1 is in the shape of a strip, the handle 2 is in the shape of a strip, the clamping part 1 and the handle 2 are coplanar and integrally formed by a mould. The other ends of the two handles 2 are welded together.

[0039] Specifically, the width d of the clamping portion 1 is 3mm-5mm. Preferably, the clamping portion 1 has a width d of 3.5 mm.

...

Embodiment 2

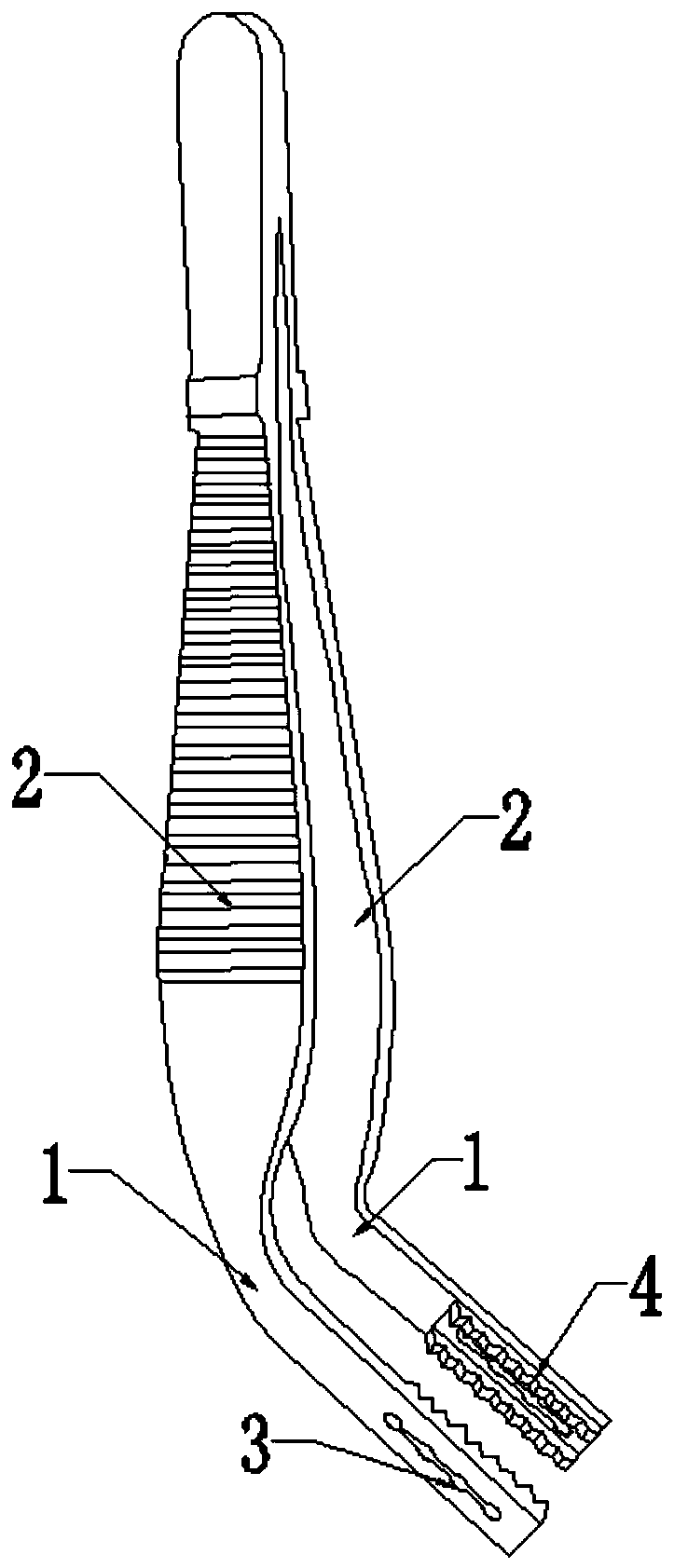

[0055] On the basis of Example 1, as Figure 3-Figure 4 As shown, the included angle between the clamping part 1 and the handle 2 is 110-180°.

[0056] Specifically, the clamping part 1 is coplanar with the handle 2, and the angle e between the centerline of the clamping part 1 and the centerline of the handle 2 preferably ranges from 110° to 160°. Preferably, the included angle e is 130°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com