A kind of non-twisted sheath-core type two-component elastic yarn and its preparation method

A skin-core, elastic yarn technology, applied in filament/thread forming, adding pigment in spinning solution, conjugated synthetic polymer rayon, etc. problem, to achieve the effect of large porosity, stable curling and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

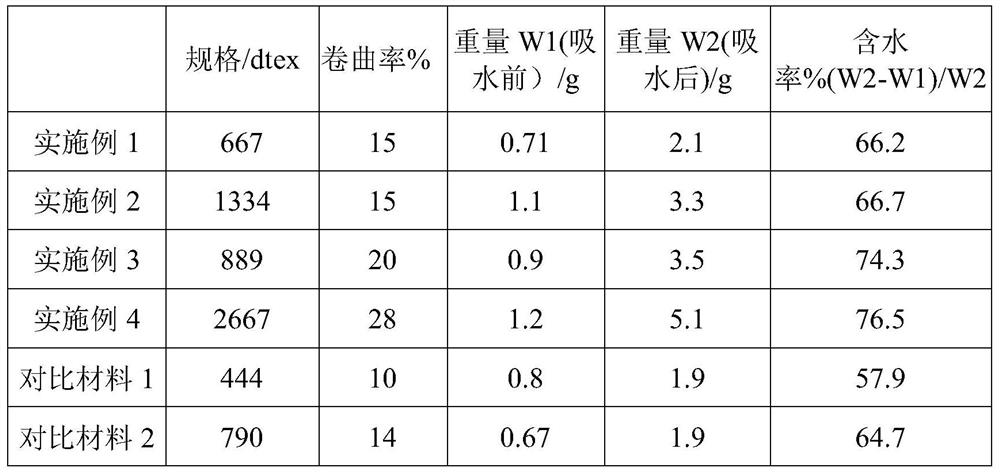

Examples

Embodiment 1

[0040] A preparation method of a non-twisted sheath-core type two-component elastic yarn is as follows:

[0041] (1) The material of the skin layer is a semi-glossy hydrophilic modified polyester with a melting point of 220°C, an intrinsic viscosity of 0.64dl / g, and a conventional moisture regain of 1.5%. The core material is a semi-glossy conventional polyester with a melting point of 261°C and an intrinsic viscosity It is 0.69dl / g, and the mass ratio of cortex material and core layer material is 20:80;

[0042] The skin-core type two-component composite spinning method is adopted: the skin layer material and the core layer material are melted through the screw, the spinning temperature of the skin layer is controlled at 272°C, and the spinning temperature of the core layer is 288°C, and then the spinning of the skin layer and the core layer is carried out by a metering pump. The silk melt is transported to the spinning assembly, and at the same time passes through a distribu...

Embodiment 2

[0048] A preparation method of a non-twist sheath-core type two-component elastic yarn is the same as that in Example 1, and step (3) passes 2 sheath-core type elastic yarns with S twist direction and 2 Z twist direction through a composite machine, Prepare non-twisted sheath-core bicomponent elastic yarn 2.

[0049] The cross-section of the monofilament of the non-twist sheath-core bicomponent elastic yarn 2 is a sheath-core structure, the fineness is 1334dtex, the crimp shrinkage rate is 15%, no network point, no oil agent, no twist.

Embodiment 3

[0051] A method for preparing colored non-twisted sheath-core type two-component elastic yarn is as follows:

[0052] (1) The skin layer material is bright hydrophilic modified polyester without matting agent, the melting point is 225°C, the intrinsic viscosity is 0.67dl / g, the official moisture regain is 1.2%, and the core layer material is semi-gloss conventional polyester and carbon Black masterbatch (accounting for 3% of the mass ratio of the core layer), with a melting point of 261°C, an intrinsic viscosity of 0.69dl / g, and a mass ratio of the skin layer material to the core layer material of 18:82;

[0053] Using the sheath-core type two-component composite spinning method, the carbon black masterbatch and semi-gloss conventional polyester are mixed to form the core layer material, and then the skin layer material and the core layer material are melted by the screw, and the skin layer spinning temperature is controlled at 273°C. The spinning temperature of the core layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com