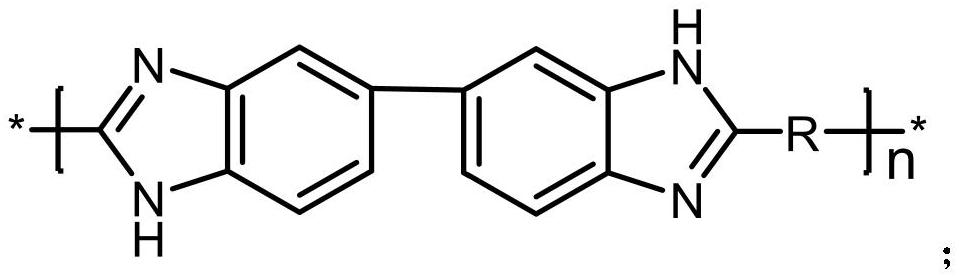

A method for preparing polybenzimidazole-based porous polymer ion-exchange membranes by gas-phase induced phase inversion method and its application

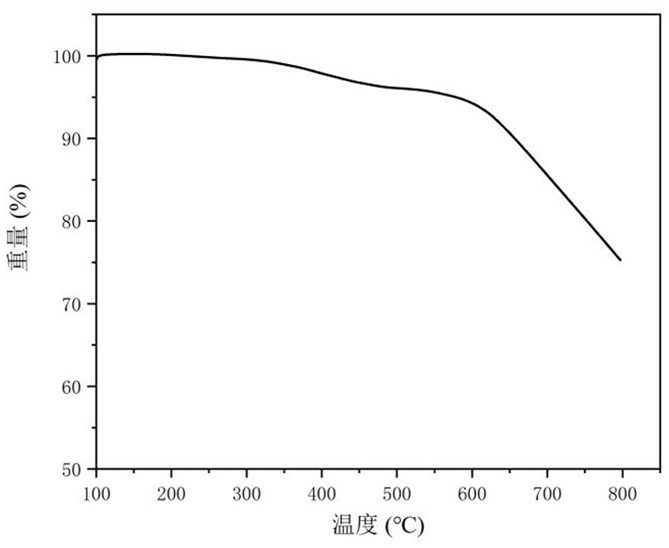

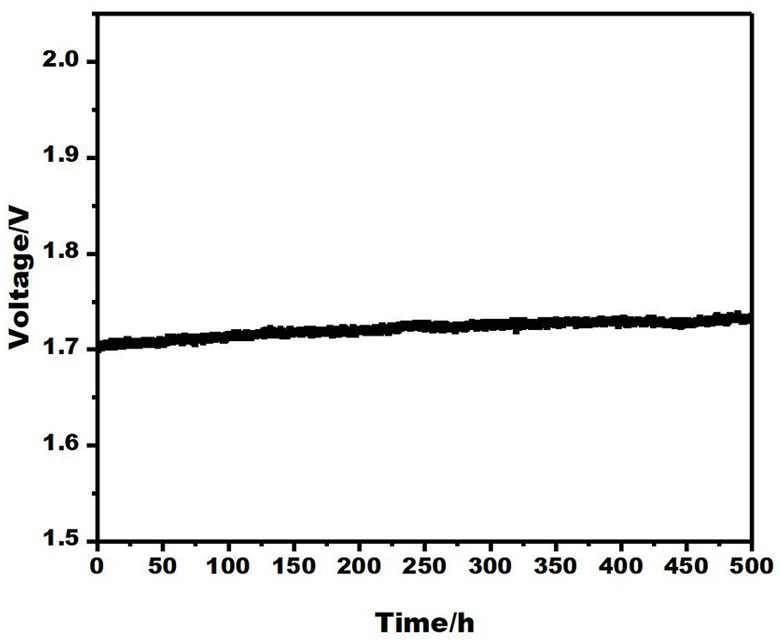

A porous polymer, ion exchange membrane technology, applied in the direction of diaphragms, organic diaphragms, electrolytic components, etc., to achieve the effects of easy mass production, simple preparation method, good thermal stability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Such as figure 1 with figure 2 Shown a kind of adopting gas-phase induced phase inversion method to prepare the method for the porous polymer ion-exchange membrane based on polybenzimidazole, comprises the following steps:

[0039] 1. Preparation of uniform film-forming solution

[0040] This step is specifically: dissolving polybenzimidazole (mPBI) in DMAc at room temperature, stirring for 1 hour, and preparing a 12.5 wt% uniform and transparent casting solution;

[0041] 2. Preparation of Porous Polybenzimidazole Polymer Electrolyte Separator by Gas Phase Inversion Method

[0042] This step is specifically as follows: a uniform solution of mPBI with a concentration of 12.5wt% is spread on a glass plate to form a solution film with an average thickness of 40±10 μm, and then the glass plate with the liquid film is quickly placed at 80 °C and the humidity is 60 °C. % air environment for 20min. Then take out the glass plate and immerse it in 3 liters of deionized wat...

Embodiment 2

[0049] A method for preparing a polybenzimidazole-based porous polymer ion-exchange membrane using a gas-phase induced phase inversion method, comprising the following steps:

[0050] 1. Preparation of uniform film-forming solution

[0051] This step is specifically: dissolving polybenzimidazole (mPBI) in DMAc at room temperature, stirring for 1 hour, and preparing a 12.5 wt% uniform and transparent casting solution;

[0052] 2. Preparation of Porous Polybenzimidazole Polymer Electrolyte Separator by Gas Phase Inversion Method

[0053] This step is specifically as follows: spread the uniform solution of mPBI with a concentration of 12.5wt% on a glass plate to form a solution film with an average thickness of 40 ± 10 μm, and then quickly place the glass plate with the liquid film at 80 ° C and a humidity of 70 % air environment for 20min. Then take out the glass plate and immerse it in 3 liters of deionized water at room temperature for 30 minutes, wash the porous membrane an...

Embodiment 3

[0056] A method for preparing a polybenzimidazole-based porous polymer ion-exchange membrane using a gas-phase induced phase inversion method, comprising the following steps:

[0057] 1. Preparation of uniform film-forming solution

[0058] This step is specifically: dissolving polybenzimidazole (mPBI) in DMAc at room temperature, stirring for 1 hour, and preparing a 12.5 wt% uniform and transparent casting solution;

[0059] 2. Preparation of Porous Polybenzimidazole Polymer Electrolyte Separator by Gas Phase Inversion Method

[0060] This step is specifically as follows: a uniform solution of mPBI with a concentration of 12.5wt% is spread on a glass plate to form a solution film with an average thickness of 40 ± 10 μm, and then the glass plate with the liquid film is quickly placed at 80 ° C and the humidity is 80 % air environment for 20min. Then take out the glass plate and immerse it in 3 liters of deionized water at room temperature for 30 minutes, wash the porous memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com