Method for esterification separation of by-product diesel oil of polyunsaturated fatty acid through selective fatty acid

A technology of unsaturated fatty acids and fatty acid esters, which is applied in the direction of fatty acid esterification, fatty acid production, fatty acid preparation/refining, etc., and can solve problems such as low efficiency, small scale, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The hydrolyzed microalgae free fatty acid ( Schizochytrium limacinum ) , Methanol (molar ratio 1:30) was added to the reactor, and a selective catalyst was added and heated to 85 degrees Celsius to start the reaction with stirring at 150rpm. The reaction mixture was taken out at regular intervals to measure the fatty acid ester content generated.

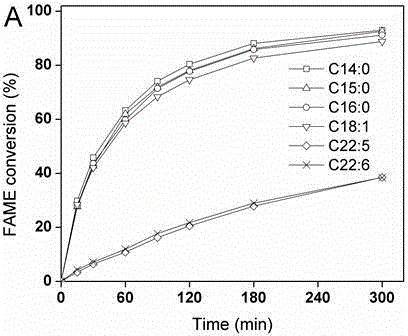

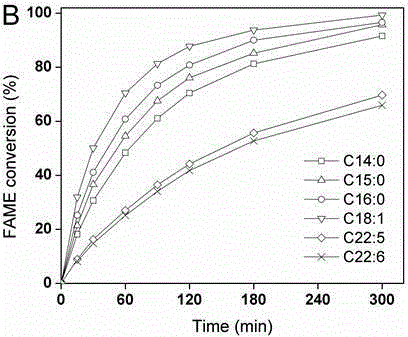

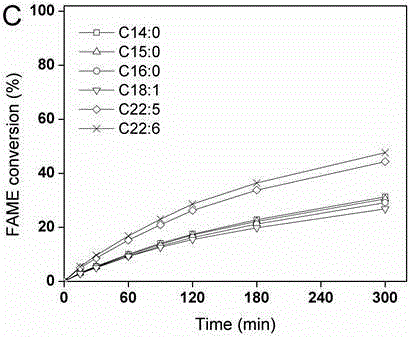

[0030] figure 1 It is shown that catalysts A, B and C have different selectivity effects. Catalysts A and B have strong selectivity to short-chain saturated fatty acids and low unsaturated fatty acids, but weak catalytic ability to PUFA (C22:5 and C22:6). The selectivity of catalyst C to different fatty acids is not as obvious as that of A and B. Moreover, the catalytic ability of catalyst C to PUFA (C22:5 and C22:6) was stronger than that of catalysts A and B.

[0031] After the reaction is over ( figure 1 A), 72% of C22:5 and C22:6 were still present in the form of free fatty acids, and their concentration in fr...

Embodiment 2

[0033] The hydrolyzed microalgae free fatty acid ( Nannochloropsis salina ) , Methanol (molar ratio 1:30) was added to the reactor, and a selective catalyst was added and heated to 85 degrees Celsius to start the reaction with stirring at 150rpm. The reaction mixture was taken out at regular intervals to measure the fatty acid ester content generated.

[0034] Figure 2 shows that catalysts A, B and C have different selectivity effects. Catalysts A and B have strong selectivity to short-chain saturated fatty acids and low unsaturated fatty acids, but weak catalytic ability to PUFA (C20:5 and C20:4). The selectivity of catalyst C to different fatty acids is not as obvious as that of A and B. Moreover, the catalytic ability of catalyst C to PUFA (C20:5 and C20:4) was stronger than that of catalysts A and B.

[0035] After the reaction is over ( figure 2 A), 78% of C20:5 and C20:4 were still present in the form of free fatty acids, and their concentration in free fatty a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com