Application of an organic-inorganic porous composite membrane in flow energy storage battery

A technology of liquid flow energy storage battery and porous composite membrane, which is applied in the components of fuel cells, battery electrodes, battery pack components, etc. Reduced oxidative stability, improved conductivity, slow effect of phase inversion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 4.5 g of polybenzimidazole was dissolved in 10.5 g of DMAC, and 0.225 g of gas-phase SiO was added 2 , stirred for 2 hours to form a uniform and transparent polymer solution, which was scraped on a glass plate with a glass rod, and the thickness of the scraping was 200 microns. Then place the glass plate together with the resin in an air environment at 50°C and 100% humidity. After 5 minutes, the glass plate was taken out and immersed in 5 L of water to wash the porous membrane. The internal pore diameter of the membrane is about 1um, the membrane surface pore diameter is about 5nm, and the membrane surface porosity is 50%.

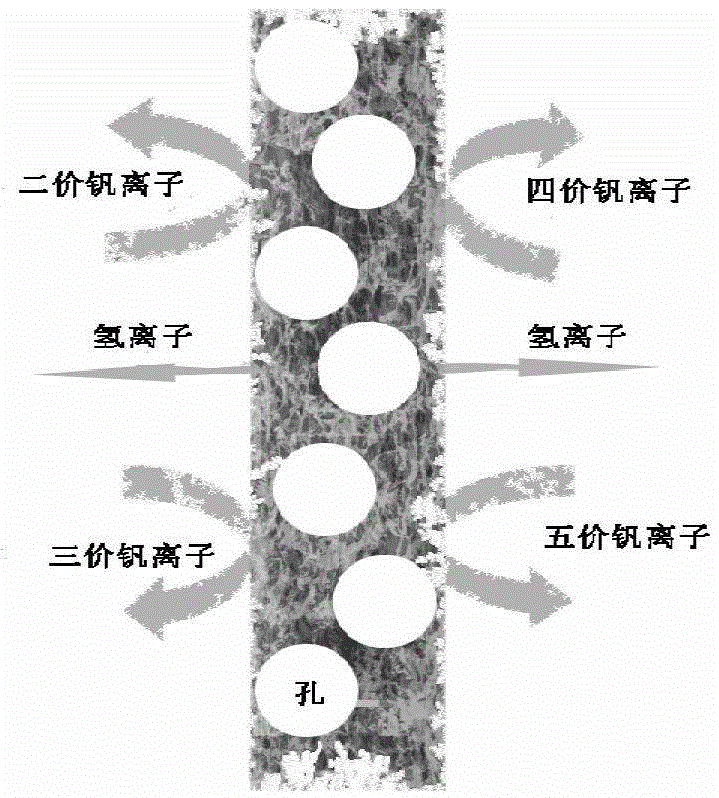

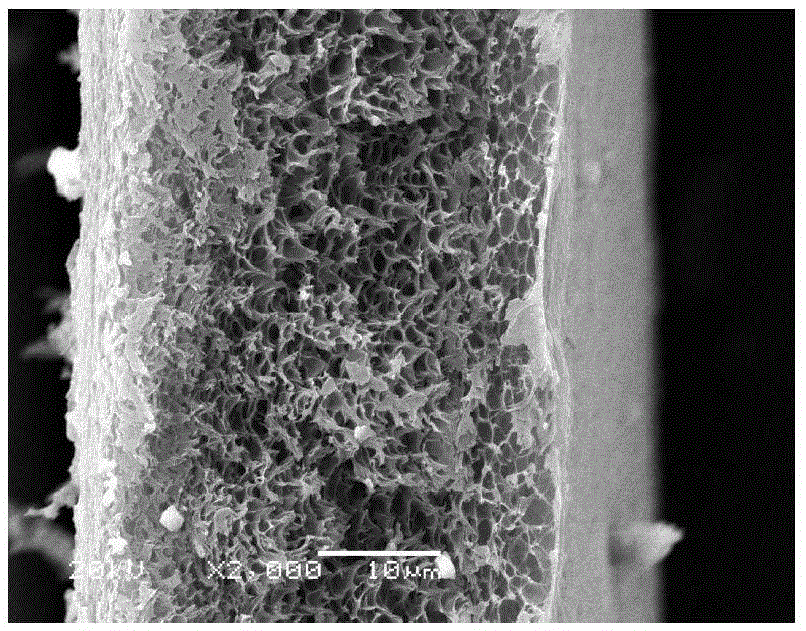

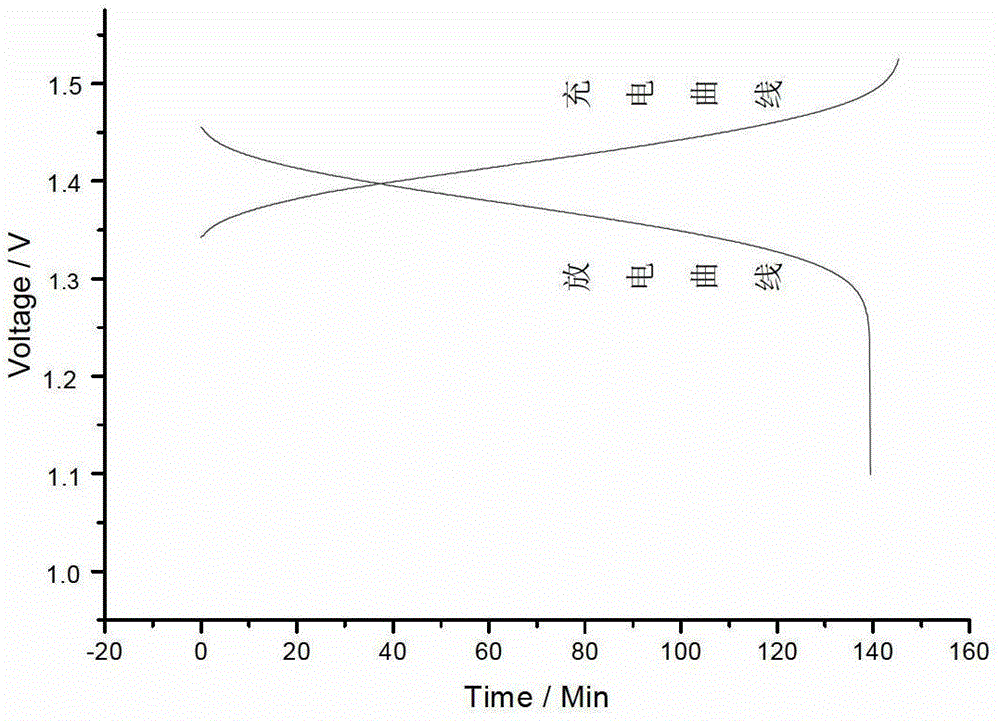

[0039] figure 2 A cross-sectional SEM picture of the prepared membrane material is given, showing a regular pore structure. The all-vanadium flow energy storage battery is assembled by using the prepared porous diaphragm, the activated carbon felt is the catalytic layer, the graphite plate is the bipolar plate, and the effective area of the m...

Embodiment 2

[0041] 4.5 g of polybenzimidazole was dissolved in 10.5 g of DMAC, and 0.09 g of gas-phase SiO was added2 , stirred for 2 hours to form a uniform and transparent polymer solution, which was scraped on a glass plate with a glass rod, and the thickness of the scraping was 200 microns. Then place the glass plate together with the resin quickly in an air environment with 50°C and 100% humidity. After 5 minutes, the glass plate was taken out and immersed in 5 L of water to wash the porous membrane. The internal pore diameter of the membrane is about 0.5um, the membrane surface pore diameter is about 5nm, and the membrane surface porosity is 70%. The all-vanadium flow energy storage battery is assembled by using the prepared porous diaphragm, the activated carbon felt is the catalytic layer, the graphite plate is the bipolar plate, and the effective area of the membrane is 9cm -2 , with a current density of 80mAcm -2 , the vanadium ion concentration in the electrolyte is 1.50mol...

Embodiment 3

[0043] 5 g of polyethersulfone was dissolved in 15 g of DMAC, and 0.15 g of gas-phase SiO was added 2 , stirred for 2 hours to form a uniform and transparent polymer solution, which was scraped on a glass plate with a glass rod, and the thickness of the scraping was 200 microns. Then place the glass plate together with the resin quickly in an air environment with 50°C and 100% humidity. After 5 minutes, the glass plate was taken out and immersed in 5 L of water to wash the porous membrane. The internal pore diameter of the membrane is about 1um, the membrane surface pore diameter is about 5nm, and the membrane surface porosity is 50%. The all-vanadium flow energy storage battery is assembled by using the prepared porous diaphragm, the activated carbon felt is the catalytic layer, the graphite plate is the bipolar plate, and the effective area of the membrane is 9cm -2 , with a current density of 80mAcm -2 , the vanadium ion concentration in the electrolyte is 1.50molL -1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com