Application of an ion exchange membrane in lithium-sulfur secondary battery

A lithium-sulfur secondary battery and ion-exchange membrane technology, which is applied in the direction of lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve problems such as difficulty in meeting long-term use requirements, expensive fluorine-containing membranes, and severe swelling. Achieve the effect of maintaining ion transmission selectivity, easy mass production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

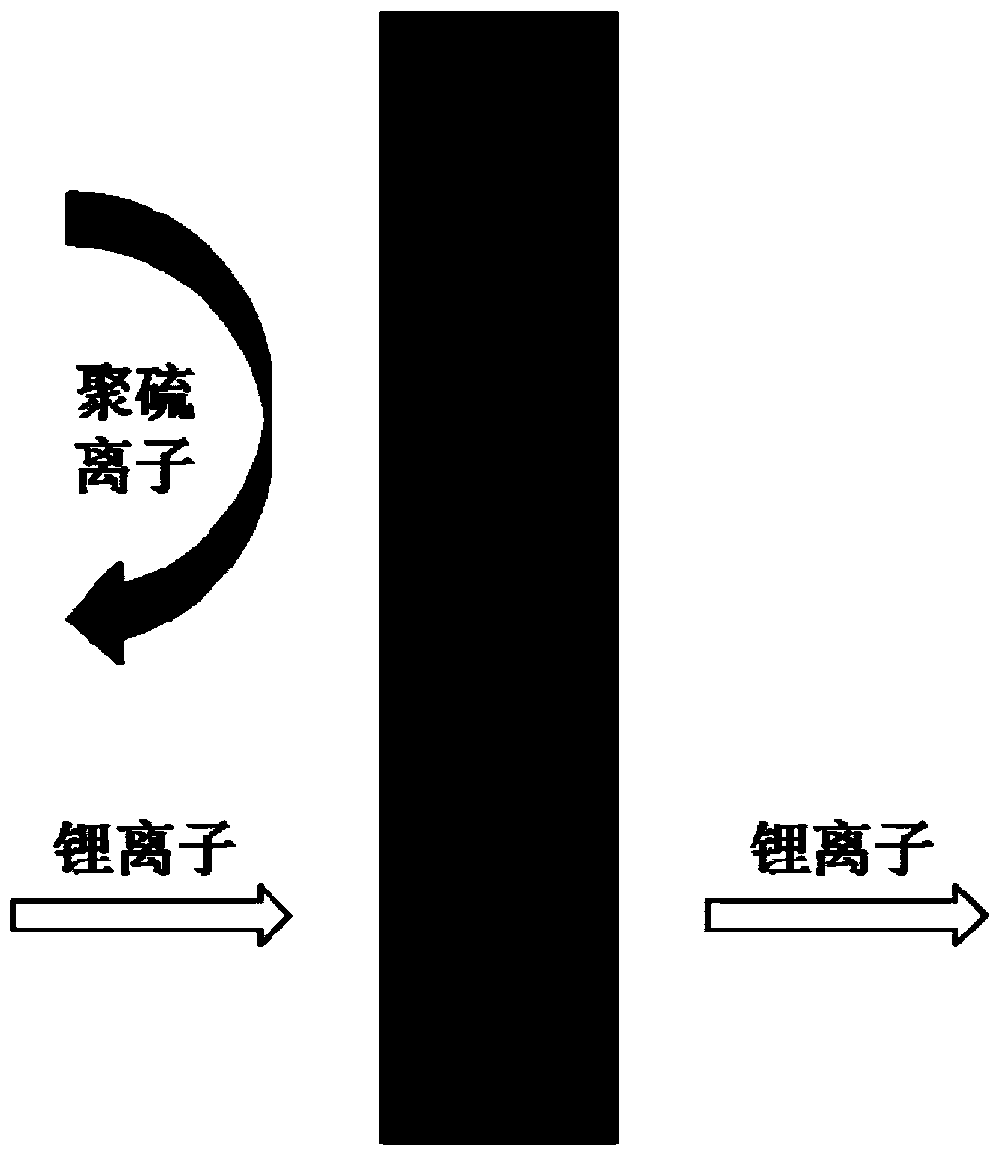

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Put 1.6 g of polyvinylidene fluoride and 0.17 g of sulfonated graphene in 10 g of DMAC, stir for 2 hours to form a uniform polymer solution, scrape and coat the glass plate with a scraper, and then quickly place the glass plate on a baking table at 70 ° C superior. After 3 hours, the completely volatilized film on the glass plate was removed, and placed in a vacuum drying oven at 70° C., with a vacuum degree of 0.1 MPa.

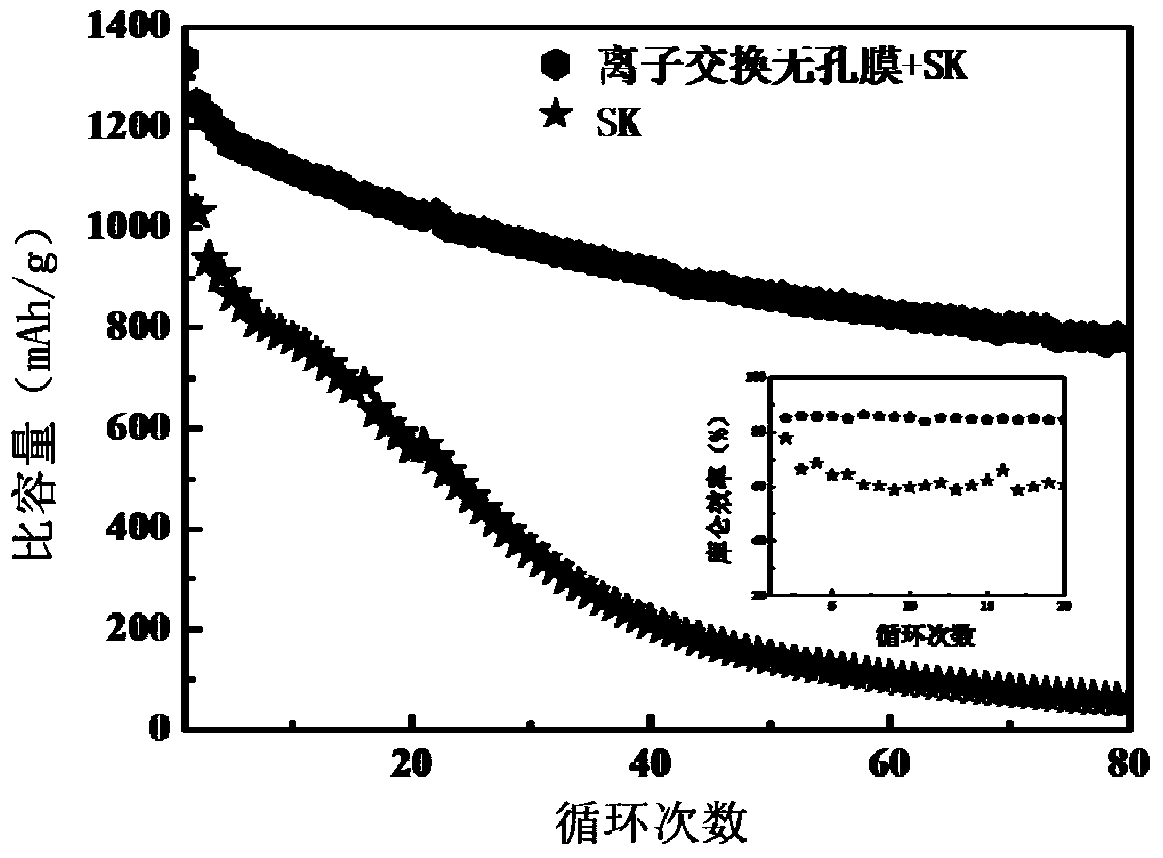

[0036] figure 2 The surface and cross-sectional scanning electron microscope pictures of the prepared membrane materials are given. The prepared ion-exchange membrane and commercial diaphragm SK (polyethylene monolayer film) are used to form a composite membrane, and a lithium-sulfur battery is assembled. The commercial carbon-sulfur composite is used as the positive electrode, and the metal lithium sheet is used as the negative electrode. 1M trifluoromethylsulfonyl The 1,3-dioxolane and ethylene glycol dimethyl ether (1:1 volume ratio) solution of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com