Wiring structure of sample detection pore plate, and sample detection pore plate

A technology of sample detection and wiring structure, which is applied to measuring devices, material analysis through electromagnetic means, instruments, etc., can solve problems such as increased process difficulty, increased wire resistance, and complex processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Preferred embodiments according to the present invention will be described in detail below with reference to the accompanying drawings. Through the accompanying drawings and corresponding descriptions, those skilled in the art will further understand the features and advantages of the present invention.

[0047] [Sample Detection Orifice Plate]

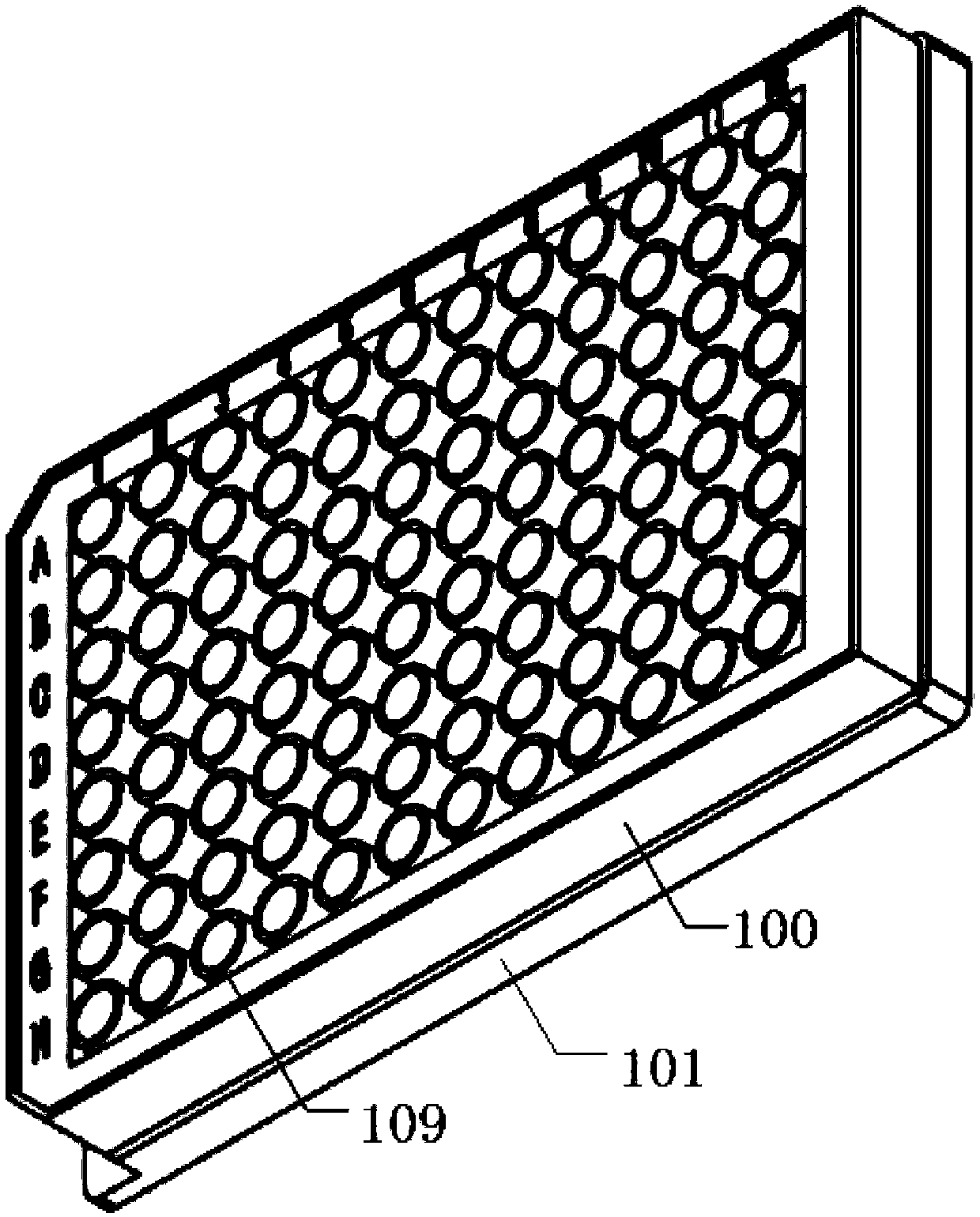

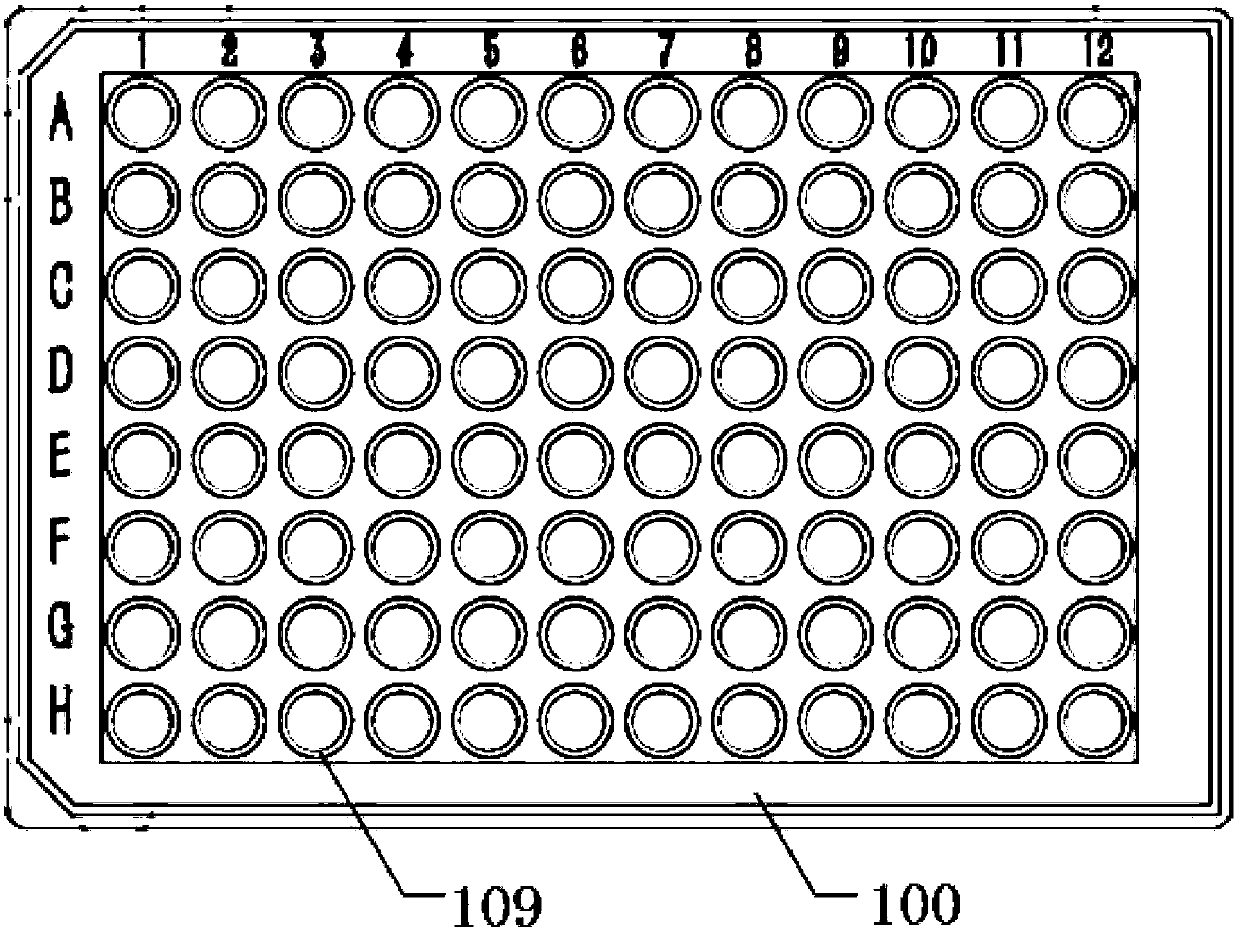

[0048] Figure 8 It is an exemplary perspective view of an example of a sample detection well plate according to an embodiment of the present invention. Figure 9 It is an exemplary plan view of the sample detection well plate according to the embodiment of the present invention as viewed from the surface side.

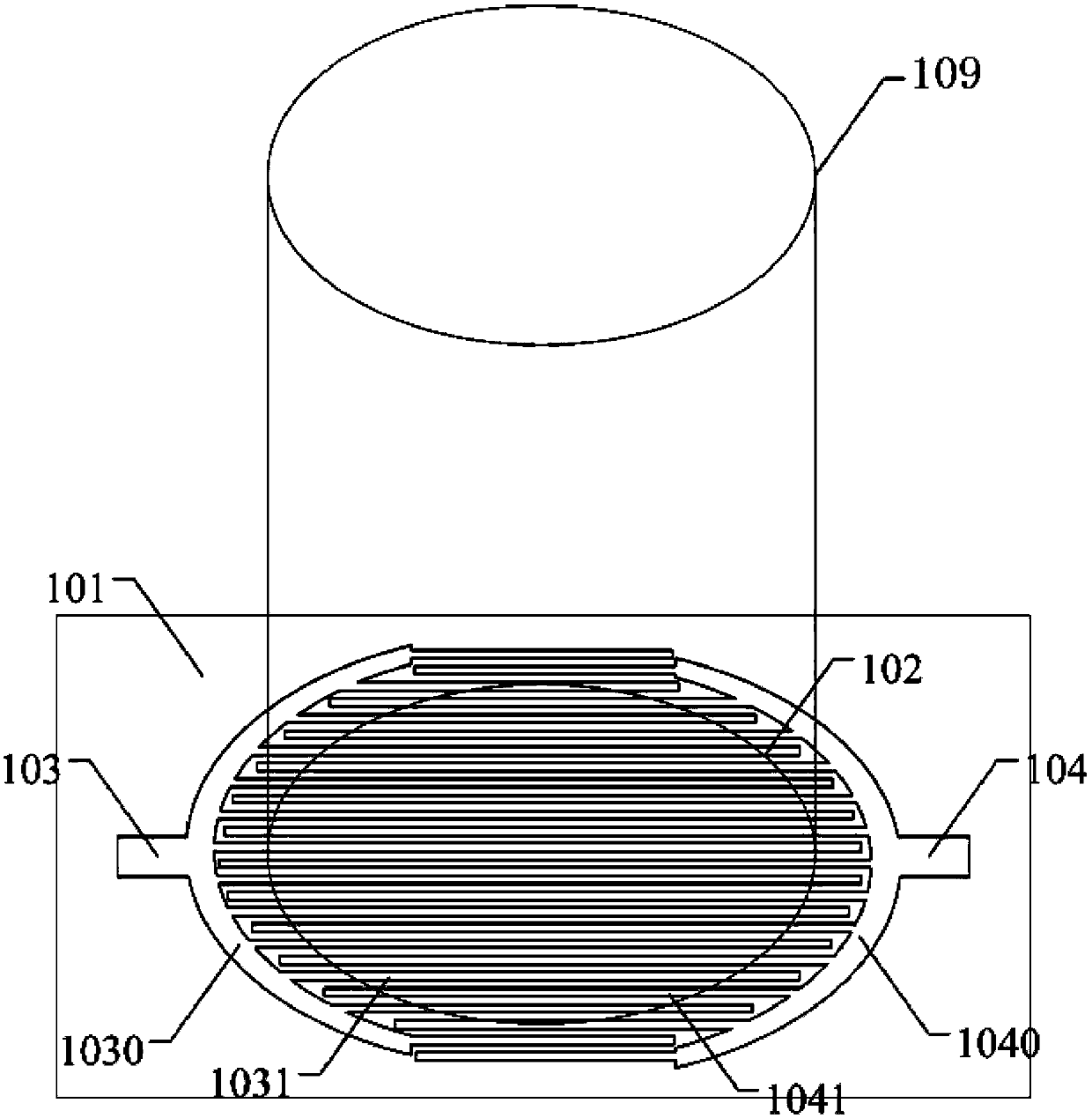

[0049] like Figure 8 and Figure 9 As shown, the sample detection well plate 200 includes a cartridge 208 . The box body 208 is usually made of transparent materials for easy observation and measurement. It has 8 rows×12 columns of wells 209, which are 96-well plates. Each column of wells is divided into 2 detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com