A rotary press fertilization device

A fertilization device and a technology of rotating and pressing down, which are applied to fertilization devices, planting methods, liquid fertilizer distribution, etc., can solve the problems of insufficient fertilization accuracy and soil backfilling, and achieve the effects of low processing cost, reliable operation and high interchangeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

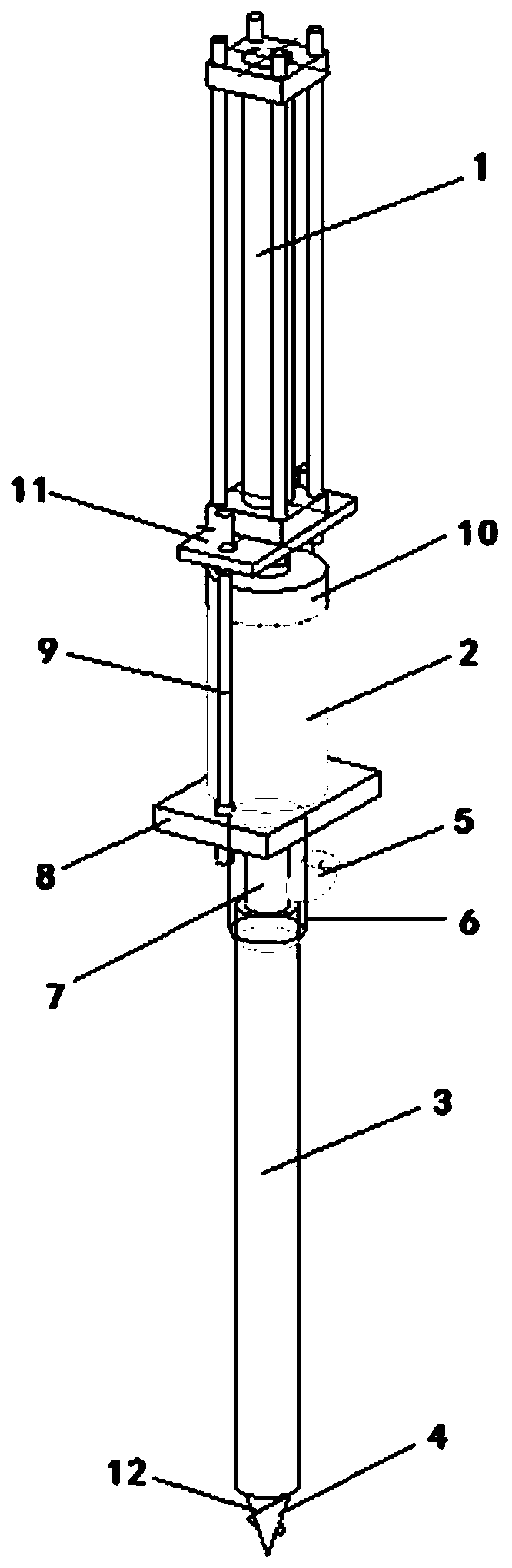

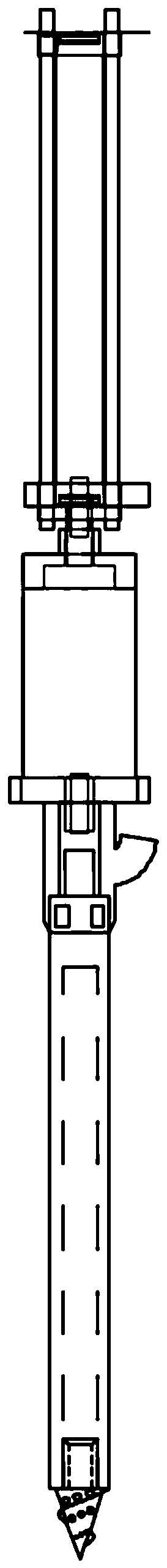

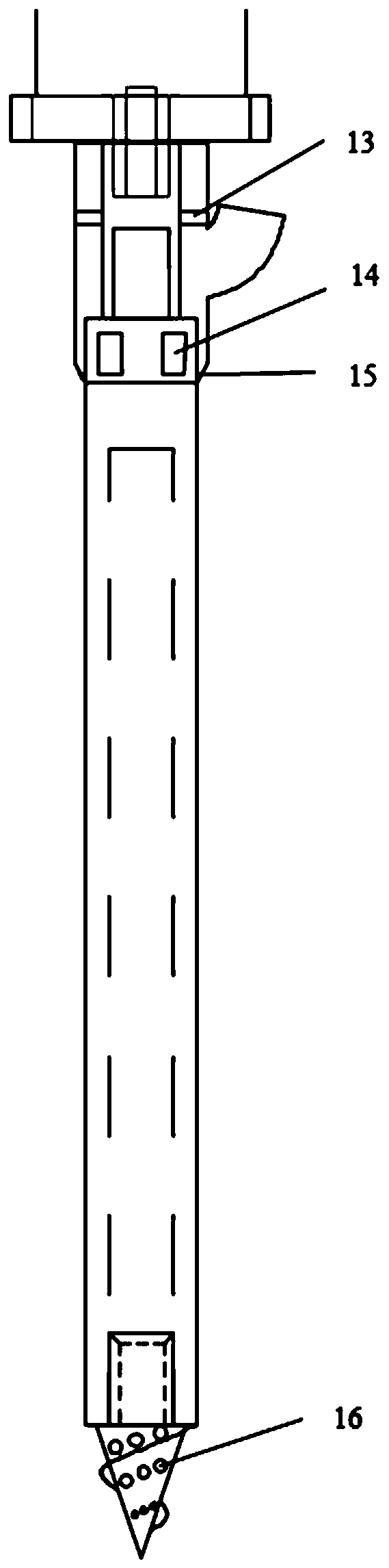

[0030] like figure 1 , figure 2 shown, combined with Figure 3-Figure 6 , the rotating and pressing fertilization device in this embodiment mainly includes hydraulic cylinder 1, hydraulic motor 2, hollow drill rod 3, drill bit, conical auger tip 4, fertilization sleeve 6, fertilization inlet 5, hollow drill rod upper end and hydraulic pressure The connecting sleeve 7 between the motors, the flange 10 between the hydraulic motor and the hydraulic cylinder, the telescopic rod 9, the connecting plate 11 and the fixed base 8 connecting the fertilization sleeve and the telescopic rod;

[0031] In this embodiment, the hydraulic cylinder 1 is installed on the connecting plate 11, the hydraulic cylinder 1 is provided with a piston rod, the piston rod is connected to one end of the flange 10, the other end of the flange 10 is fixedly connected to the hydraulic motor 2, and the flange The structure is as Image 6 As shown; the hydraulic motor 2 is installed on the fixed base, and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap