Paint spraying system of automobile steering pull rod and paint spraying method

A technology for steering rods and automobiles, which is applied to spraying devices, devices for coating liquid on the surface, and coatings, etc. It can solve problems such as different structures of steering rods, free paint materials, and potential safety hazards, so as to maintain air quality and improve operations. Efficiency, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

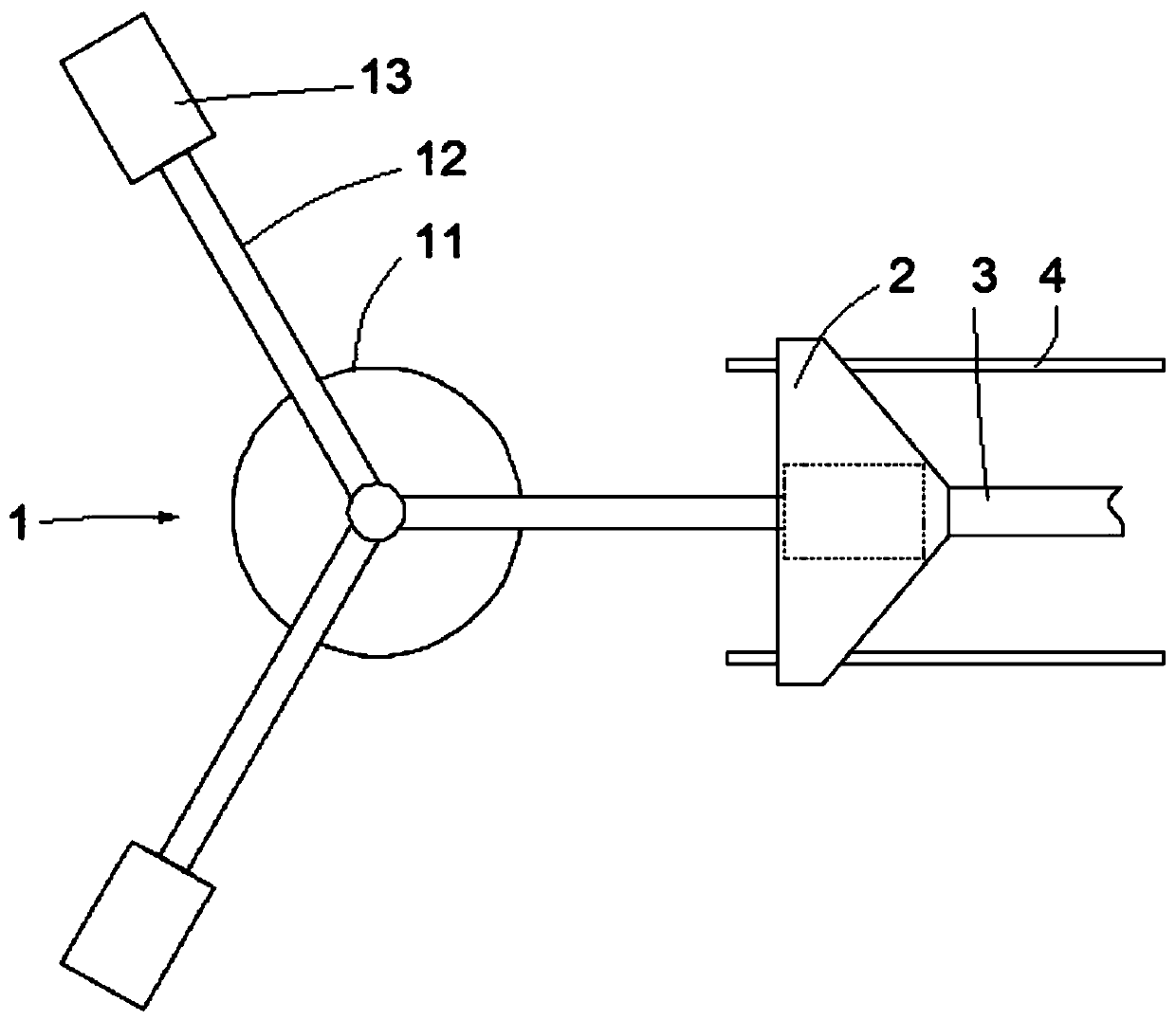

[0039] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that all the drawings of the present invention are in simplified form and use inaccurate scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

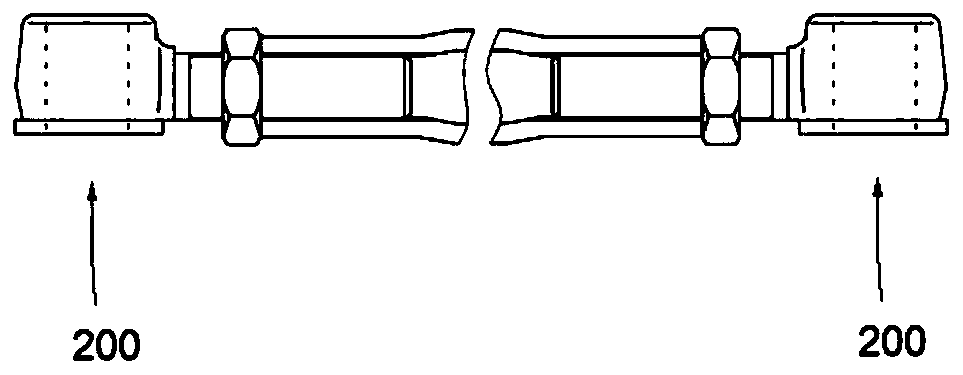

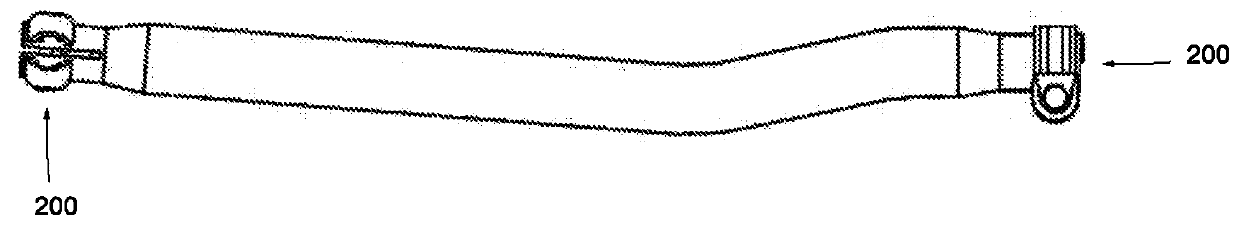

[0040] see image 3 , Figure 4 and Figure 5 A paint spraying system for an automobile steering tie rod is shown, which is used for painting the main rod 100 of the automobile steering rod (the main rod 100 refers to a single molded rod body without a ball head), which includes:

[0041] Painting mechanism (not shown in the figure);

[0042] Feeding mechanism 1, described feeding mechanism 1 is arranged near described painting mechanism, and it comprises turntable 11, and a plurality of transverse a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com