A guide device for a servo and an ultra-long-stroke fast-knife servo

A guide device and servo technology, applied in the direction of feeding devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficult manufacturing, high cost, low cost, etc., meet the requirements of cutting processing, ensure the bearing rigidity, structure The effect of compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

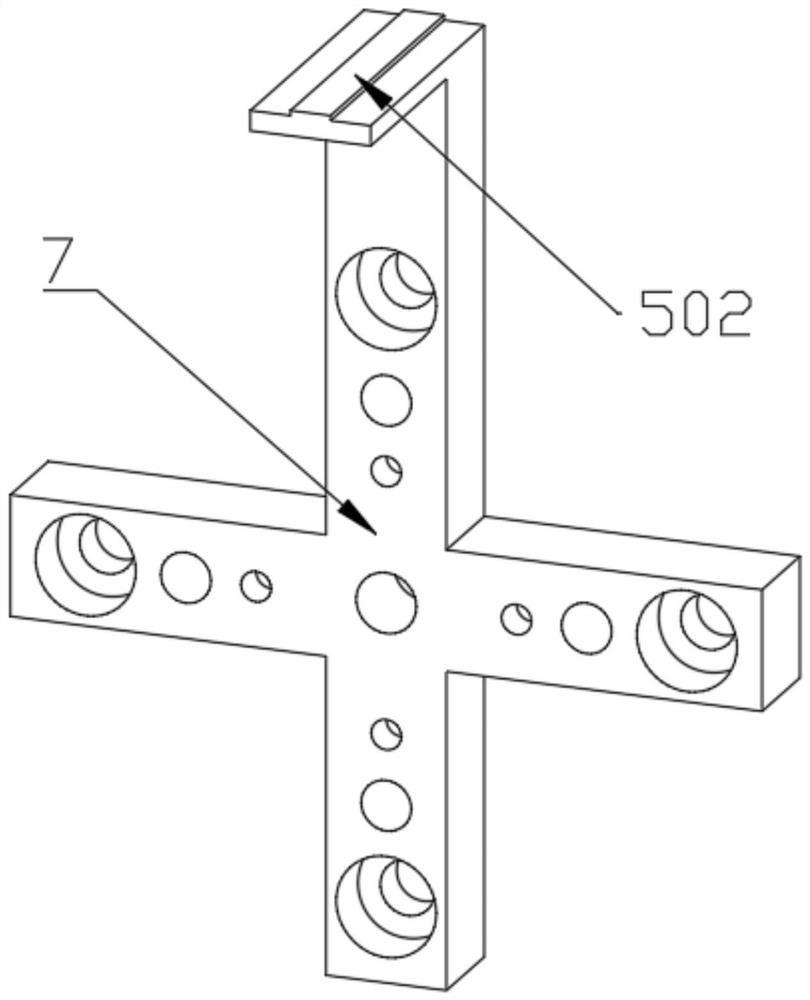

[0037] A guide device for a servo, comprising a connecting piece 7 and a leaf spring guiding mechanism 6, the leaf spring guiding mechanism 6 is connected to the connecting piece 7, and the connecting piece 7 is used to fixedly connect the driving mechanism to the leaf spring guiding mechanism 6. The leaf spring guide mechanism 6 includes 4 sets of Z-shaped folded leaf springs 601, and the 4 sets of Z-shaped folded leaf springs 601 are arranged in the outer frame of the leaf spring, and the outer frame of the leaf spring is connected to the grating assembly. The 4 sets of The zigzag folded leaf springs 601 are arranged symmetrically to the center. In this embodiment, the four zigzag folded leaf springs 601 are arranged in a cross shape, which realizes the large displacement output performance of the guide mechanism and has a compact structure, saving the space of the machine tool. The folded leaf springs 601 are arranged symmetrically in a cross to ensure the load-bearing stiff...

Embodiment 2

[0046] The difference between embodiment 2 and embodiment 1 is that the outer frame of the leaf spring in embodiment 2 is a regular hexagon, and there are 6 leaf springs at this point, and the connecting piece 7 includes 6 rods, 6 rods The starting ends of each are connected to the central symmetrical point 602 of the six rods. The block is a hexagonal prism, and after enlarging the number of folded leaf springs 601, the redundancy of the entire guiding device is also improved.

Embodiment 3

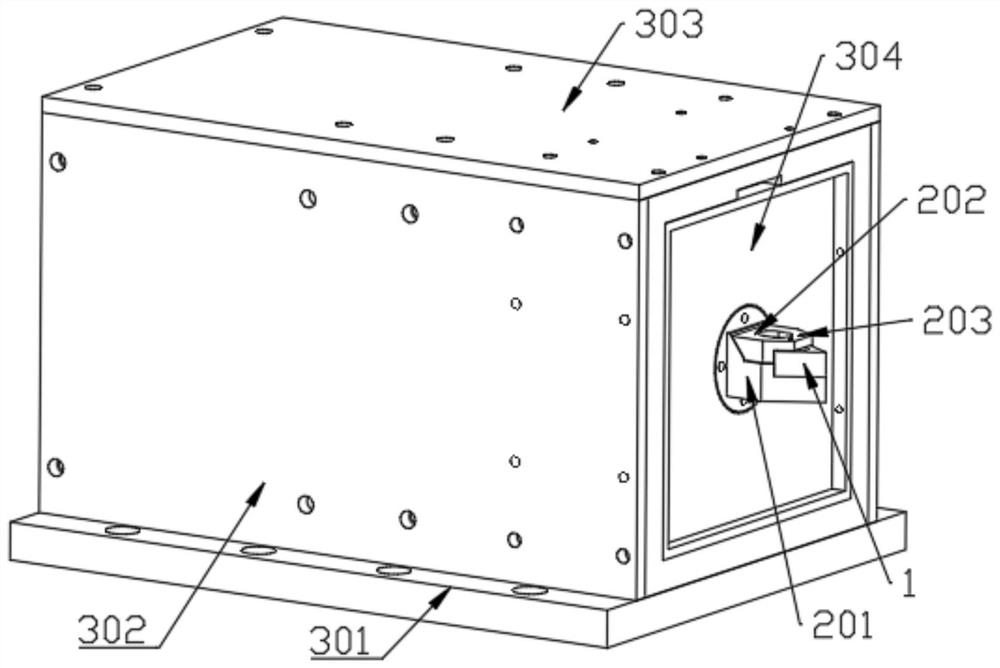

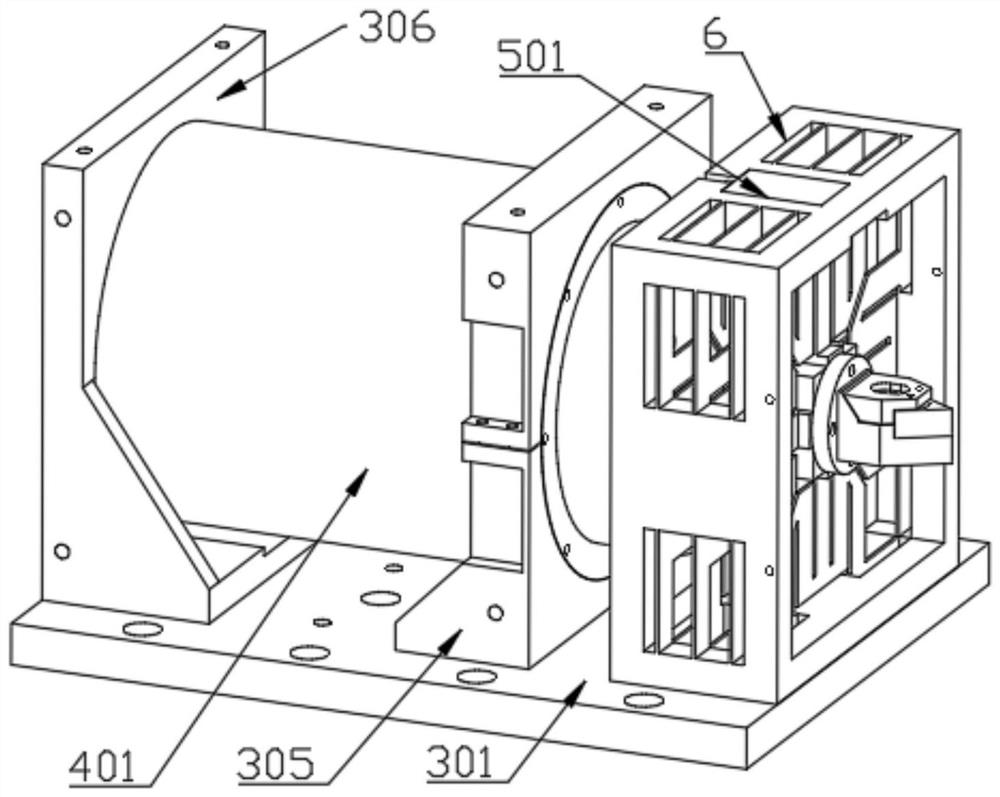

[0048] Embodiment 3 discloses an ultra-long-stroke fast-knife servo, including the guide device for the servo, and also includes a driving mechanism, a grating assembly, a turning tool holder 201, and a fixing seat. The guiding device of the device is connected to the turning tool holder 201, the driving mechanism is arranged in the fixed seat, and the grating assembly is connected to the guiding device for the servo.

[0049] Further, the tool holder includes a tool seat, a turning knife and a press block 202, the tool seat is connected to the folding leaf spring 601, a turning knife is arranged on the tool seat, and the press block 202 is connected to the tool seat , the pressing block compresses the blade;

[0050] The knife pressing block 202 is provided with a wedge-shaped surface and a slotted hole to realize pressing the blade in the horizontal direction, and compress the blade in the vertical direction by adjusting the pressing bolt;

[0051] Further, the fixed seat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com