An auxiliary device applied to spring installation

An auxiliary device and spring installation technology, applied in the field of spring installation, can solve problems such as affecting work efficiency, easy scratching of hands, injury to staff, etc., and achieve the effects of improving work efficiency, improving the scope of application, and reducing unnecessary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

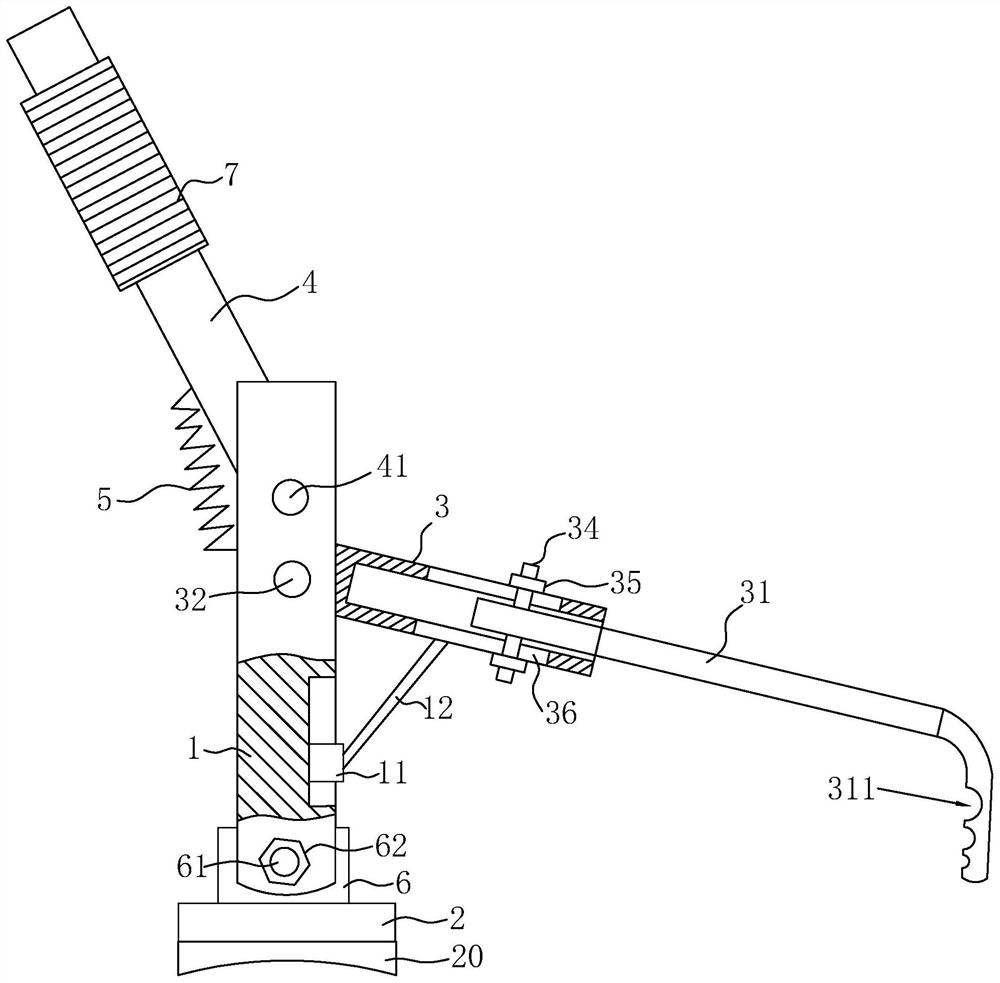

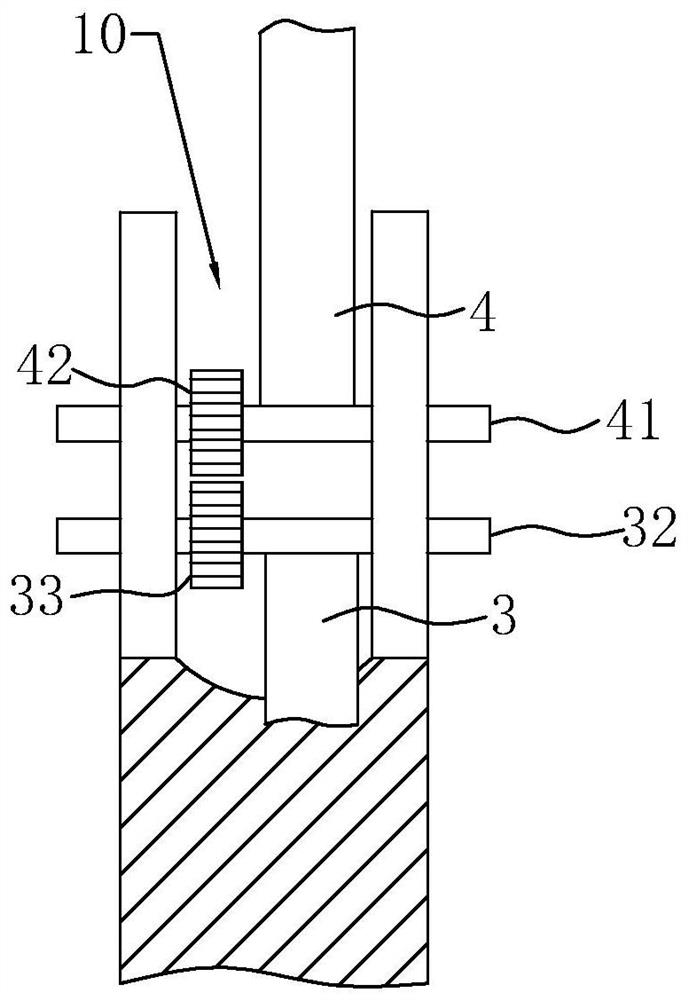

[0034] Embodiment 1: An auxiliary device applied to spring installation, such as figure 1 and figure 2 As shown, the fixed rod 1 is included, and a U-shaped through groove 10 is provided on the fixed rod 1, and a bottom plate 2 is fixed on the end of the fixed rod 1 away from the U-shaped through groove 10, and the bottom plate 2 can be connected with the frame of furniture such as sofa or bed board. match the edge of the board. In this embodiment, a hollow installation cylinder 3 is hinged in the U-shaped through groove 10, and a movable hook rod 31 is movably inserted in the installation cylinder 3, and the movable hook rod 31 can move along the extension direction of the installation cylinder 3. slide, and an adjustment assembly is provided on the installation cylinder 3, and the adjustment assembly can adjust the elongation of the movable hook rod 31.

[0035] Wherein, a rocker 4 is also hinged in the U-shaped through groove 10, and the end of the rocker 4 in the U-shap...

Embodiment 2

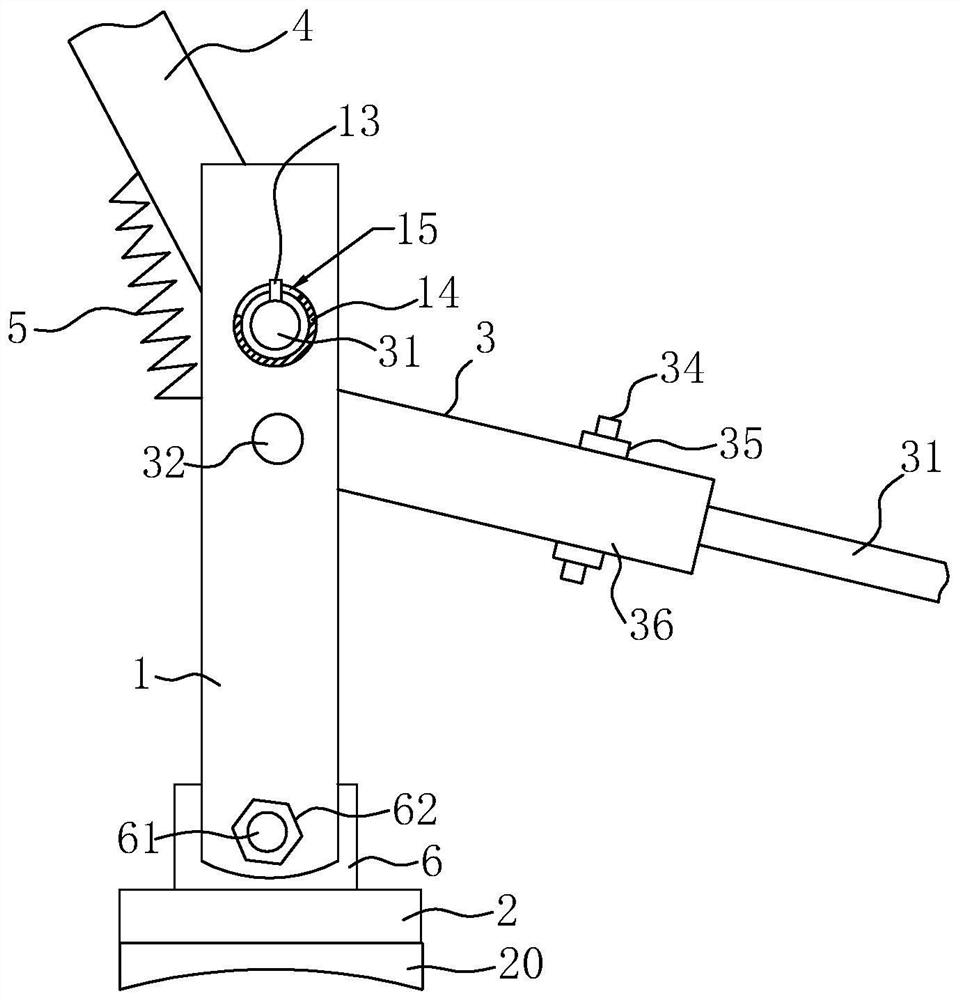

[0046] Embodiment 2: as image 3 As shown, the difference from Embodiment 1 lies in the difference of the limit assembly. In this embodiment, the limit assembly includes: the limit assembly includes: a limit block 13 fixed at the end of the first rotating rod 41, and An annular block 14 arranged around the outer wall of the fixed rod 1 around the first rotating rod 41; or a limit block 13 fixed at the end of the second rotating rod 32, and a fixed rod 1 ring arranged around the second rotating rod 32 The annular block 14 on the outer wall, the annular block 14 is apart from the first rotating rod 41 or the second rotating rod 32 preset distances, meanwhile, also offers a section arc groove 15 on the annular block 14, and the arc groove 15 can be with the position-limiting Block 13 matches, can limit the displacement that limit block 13 moves.

[0047] When the rocker 4 drives the mounting cylinder 3 to rotate, the first rotating rod 41 and the second rotating rod 32 will also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com