Combined continuous internal mixer

A kind of internal mixer and combined technology, which is applied in the field of combined continuous internal mixer, can solve the problems of not being able to discover and observe the status in time, not being able to observe and record the discharge situation, and no observation and analysis of the discharge situation, etc., to achieve increased The effect of extrusion output and capacity optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

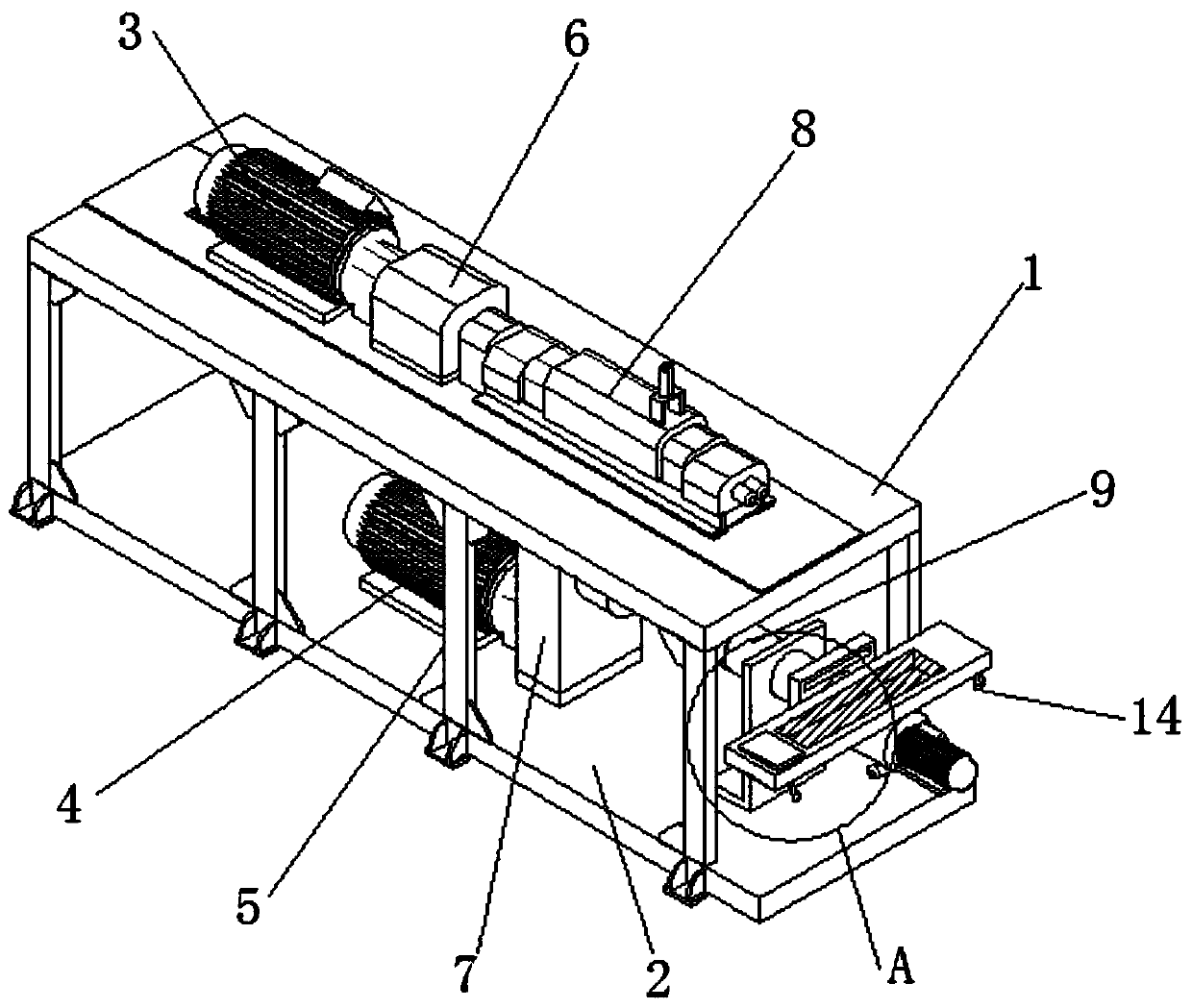

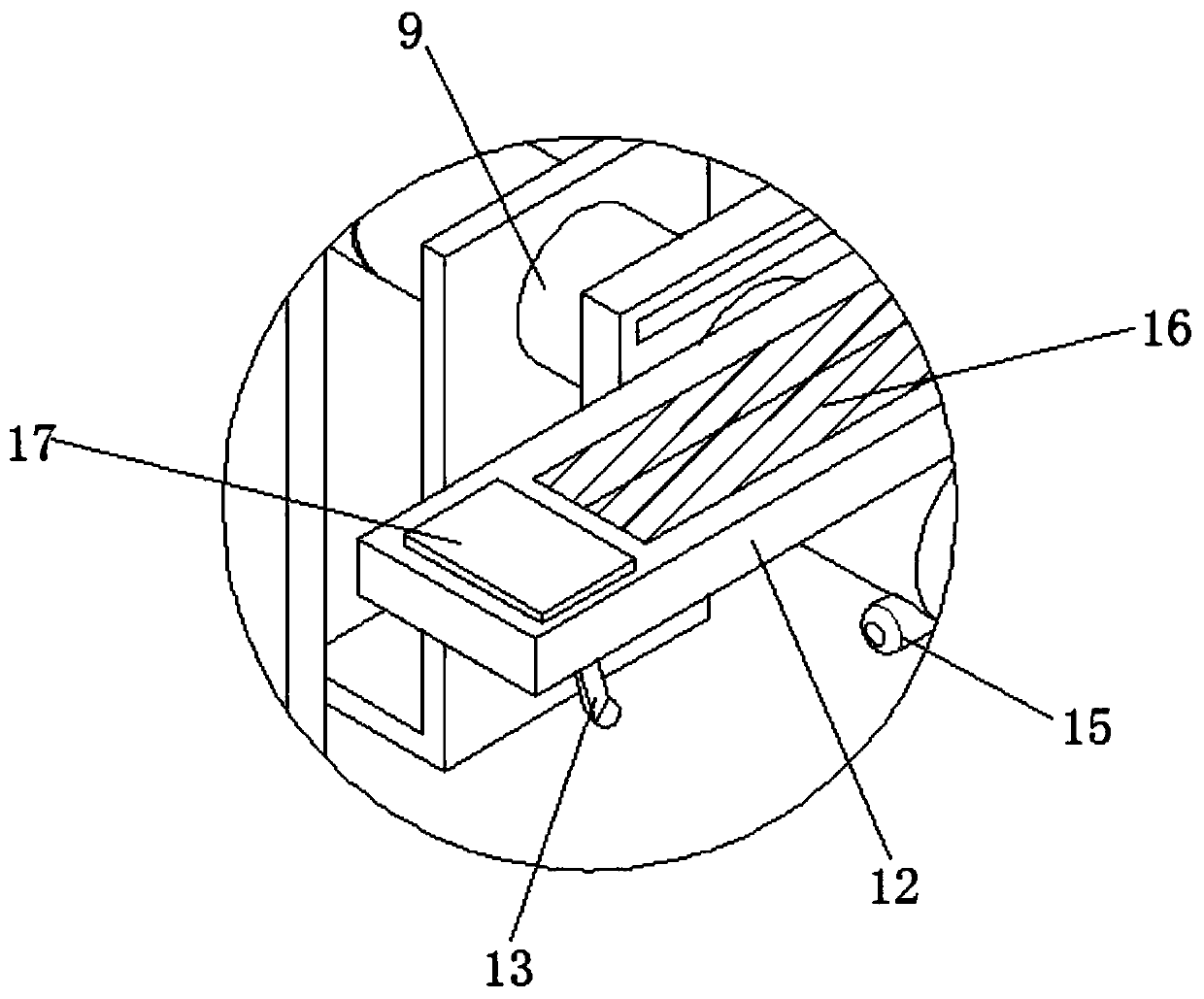

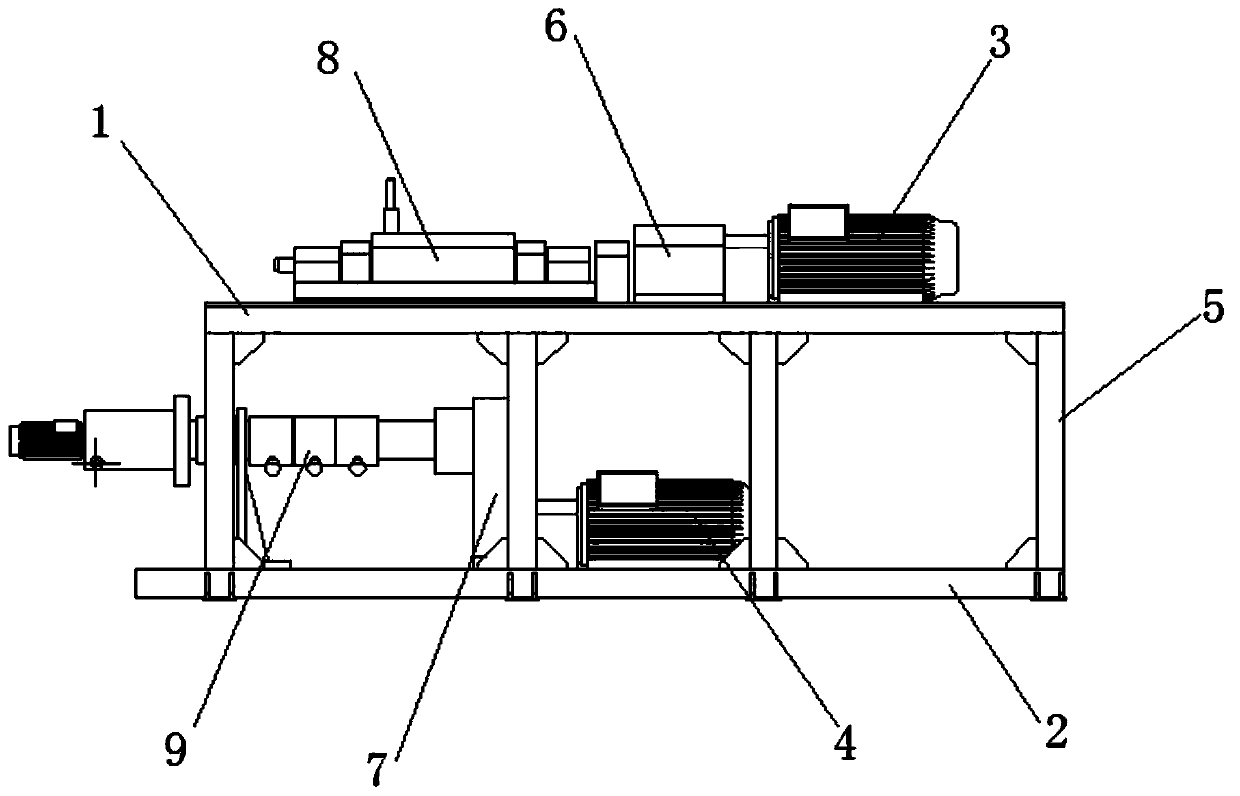

[0040] see Figure 1-5 , a combined continuous internal mixer, comprising a support frame 5 with an upper mounting plate 1 and a lower mounting plate 2 connected to the upper and lower ends respectively, the upper end of the upper mounting plate 1 is provided with a banburying mechanism, and the upper end of the lower mounting plate 2 is provided with The extrusion mechanism and the internal mixing mechanism include the upstream motor 3, the first gearbox 6 and the upstream internal mixer 8, and the upstream motor 3, the first gearbox 6 and the upstream internal mixer 8 are connected to the upper end of the upper mounting plate 1 sequentially to the right , and the upstream motor 3, the first gearbox 6 and the upstream internal mixer 8 are sequentially connected from left to right, the extrusion mechanism includes the downstream motor 4, the second gearbox 7 and the downstream internal mixer 9, the downstream motor 4, the second The gearbox 7 and the downstream internal mixer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com