Drilling assistant tool applied to hanging bar installation procedure

A technology for auxiliary tooling and processes, applied in the direction of manufacturing tools, metal processing equipment, maintenance and safety accessories, etc., can solve the problems of increasing the probability of safety accidents, dust entering the eyes of operators, reducing the drilling efficiency of installation holes, etc. , to achieve the effect of restoring clarity, ensuring drilling efficiency, and facilitating drilling progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

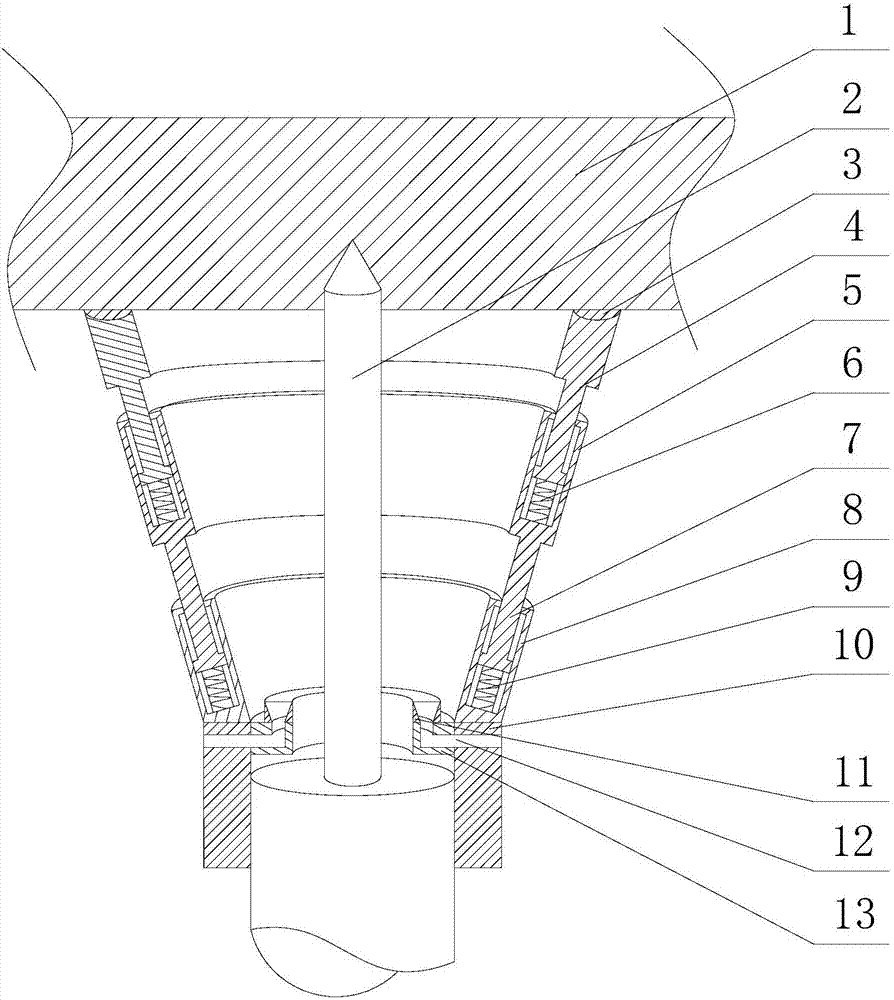

[0023] Such as figure 1 As shown, this embodiment includes a tapered tube I4, a tapered tube II5, a tapered tube III8 and a sleeve 10 with threads on the inner peripheral wall, and the small diameter section of the tapered tube III8 is connected to the upper end surface of the sleeve 10 , there is a first annular cavity on the body of the conical cylinder III8, and a plurality of springs II9 are installed on the bottom of the first annular cavity, along the circumferential direction of the small diameter section of the conical cylinder II5 on its end surface An extension section 7 is provided, and a through hole is opened on the first annular cavity. The lower section of the extension section 7 is movable through the through hole and connected with a plurality of springs II9, and is opened on the body of the conical tube II5. There is a second annular chamber, and a plurality of springs I6 are installed at the bottom of the second annular chamber, and an annular hole is opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com