Apparatus for additively manufacturing three-dimensional objects

A three-dimensional object, additive technology, applied in processing and manufacturing, additive manufacturing, metal processing equipment, etc., can solve the problems of high cost of irradiation unit, high maintenance and operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

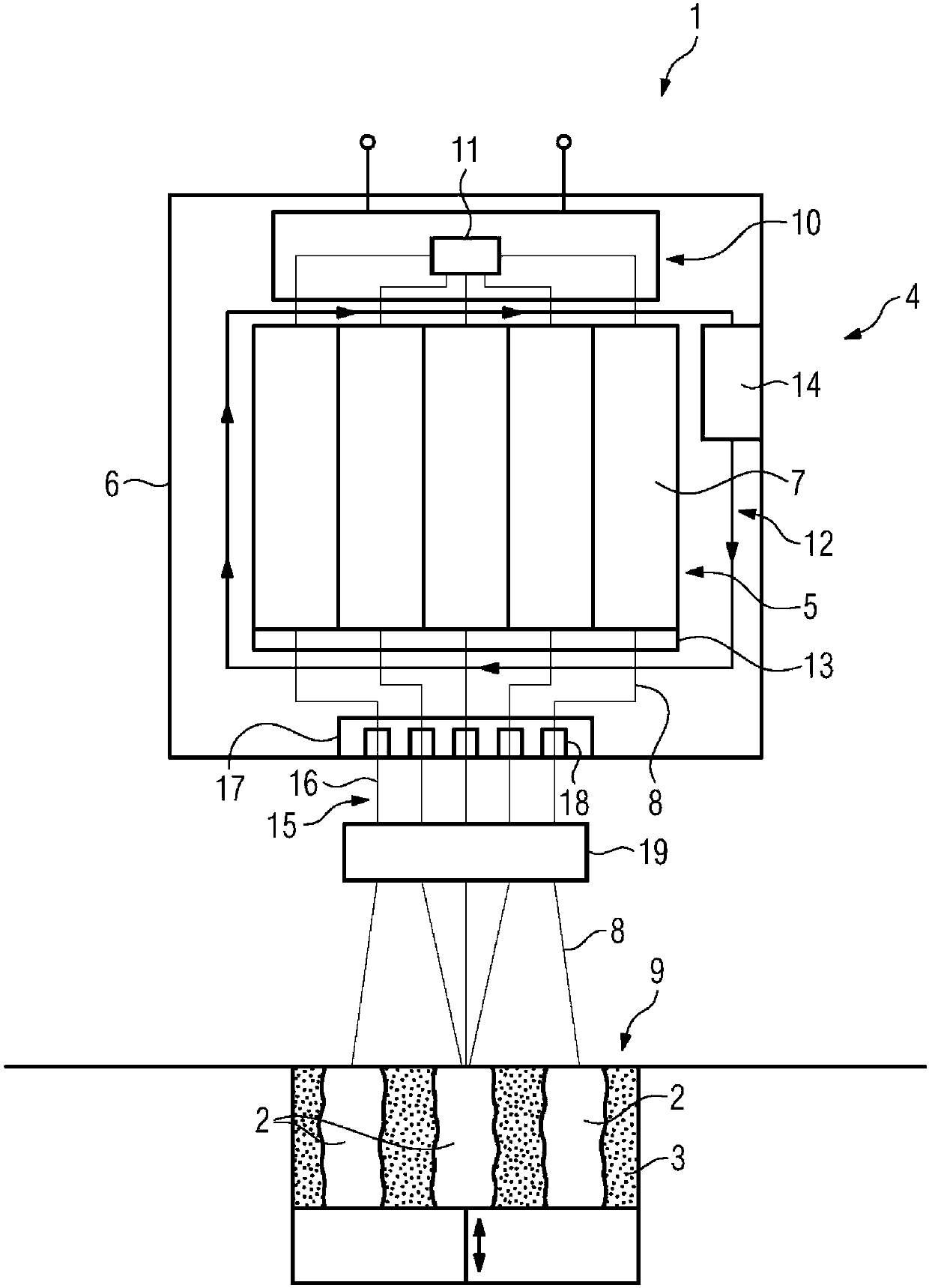

[0028] only figure 1 A device 1 is shown for the additive production of a three-dimensional object 2 by sequentially selectively irradiating and curing layers of a build material 3 curable by means of an energy beam 8 . The device 1 comprises an illumination device 4 with an illumination unit 5 comprising a common holding structure 6—in the exemplary embodiment, in the form of a common housing. The illuminating unit 5 also includes a plurality of illuminating elements 7 , five illuminating elements 7 being provided in this exemplary embodiment.

[0029] As can be seen from the figures, the illuminating elements 7 are arranged in a common holding structure 6 , in other words, wherein the common holding structure 6 encloses the illuminating elements 7 inter alia. Since the illuminating elements 7 are attached to the common holding structure 6 and to each other (optionally), the common holding structure 6 defines a spatial relationship and holds the illuminating elements 7 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com