High-precision thermal printer

A thermal printer, high-precision technology, applied in printing and other directions, can solve the problems of poor printing effect, poor graphic printing definition, low printing accuracy, etc., to avoid blurred display, improve printing effect, and improve printing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

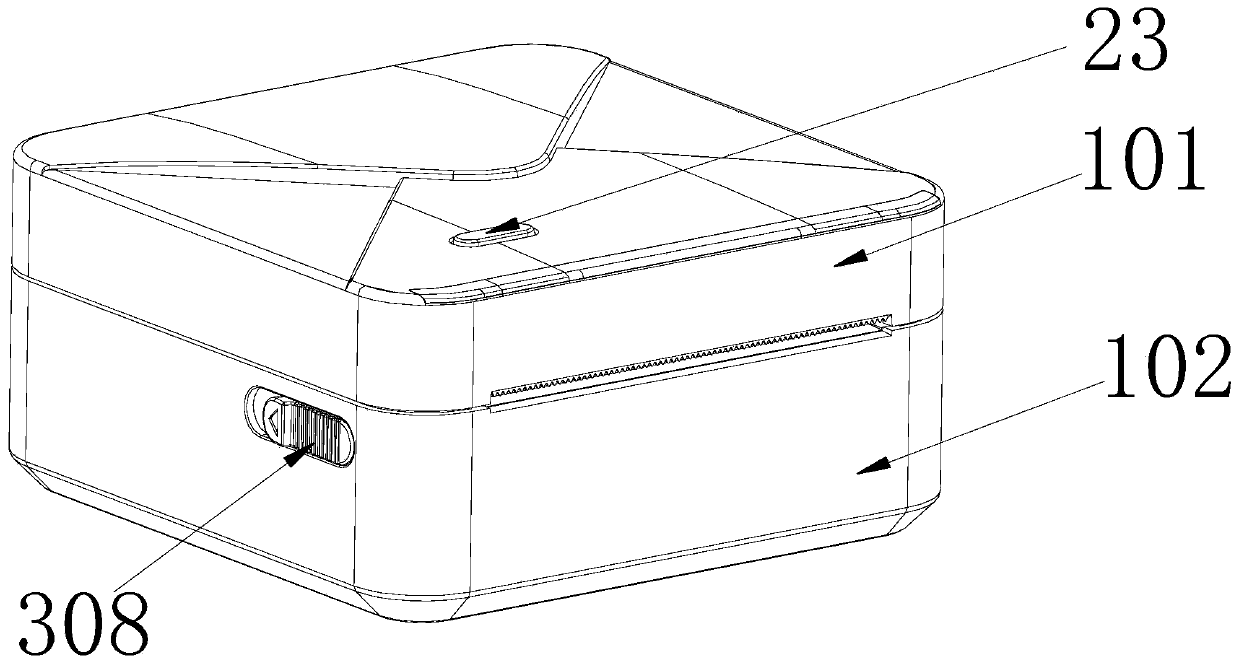

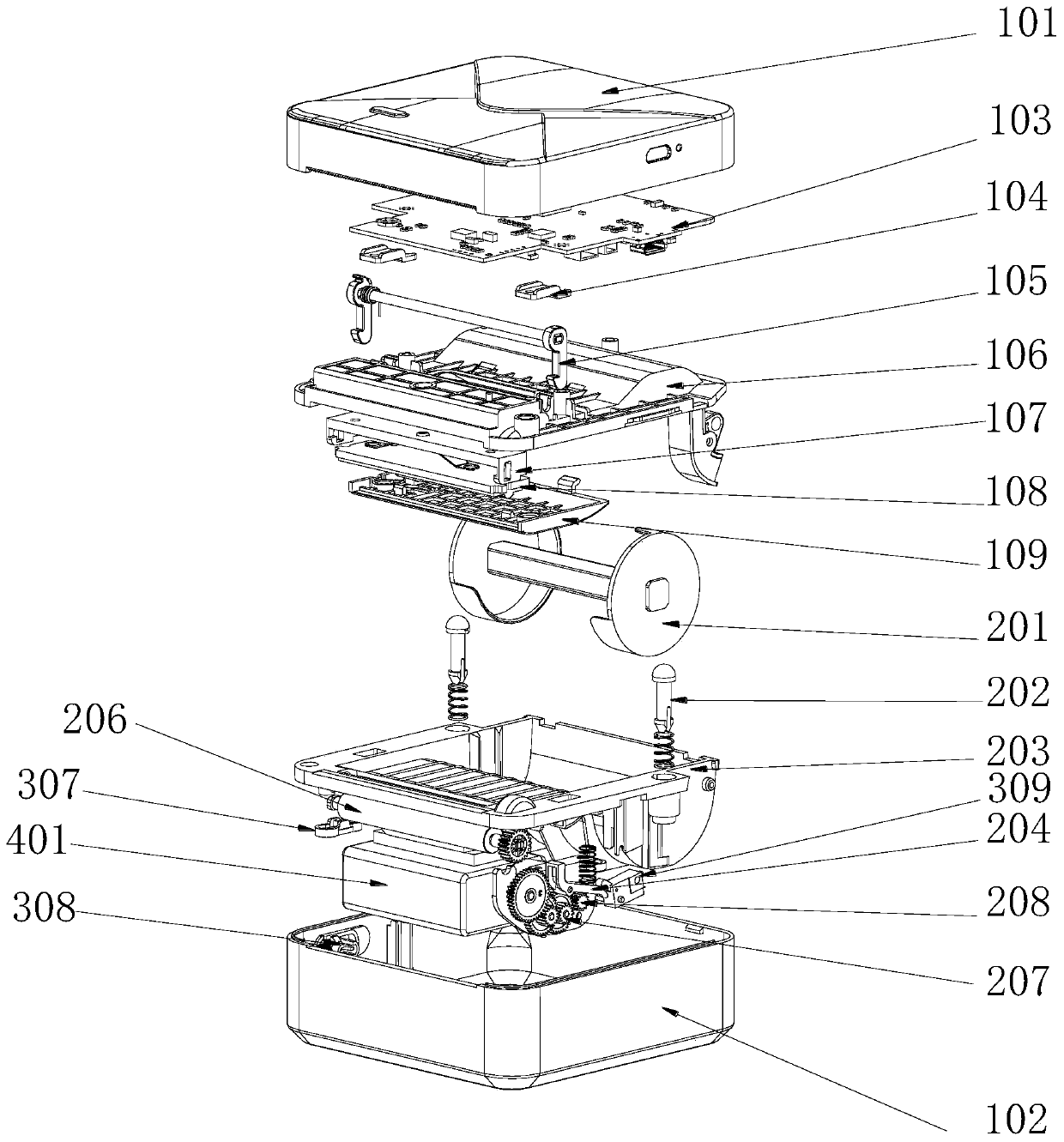

[0041] Such as Figure 1 ~ Figure 2 As shown, the high-precision thermal printer provided by the present invention includes an upper cover 101, a lower cover 102, a core and a control unit. The upper cover 101 and the lower cover 102 are combined to form a cavity, and the core and the control unit are arranged on In the cavity, the control unit is electrically connected with the movement through the FPC connecting wire 304 . The FPC connection line 304 provides the electrical connection path between the control unit and the movement, which can be customized according to the specific model structure, and can also be integrated with miniature photoelectric switches and miniature limit switch devices to improve the applicability of the module.

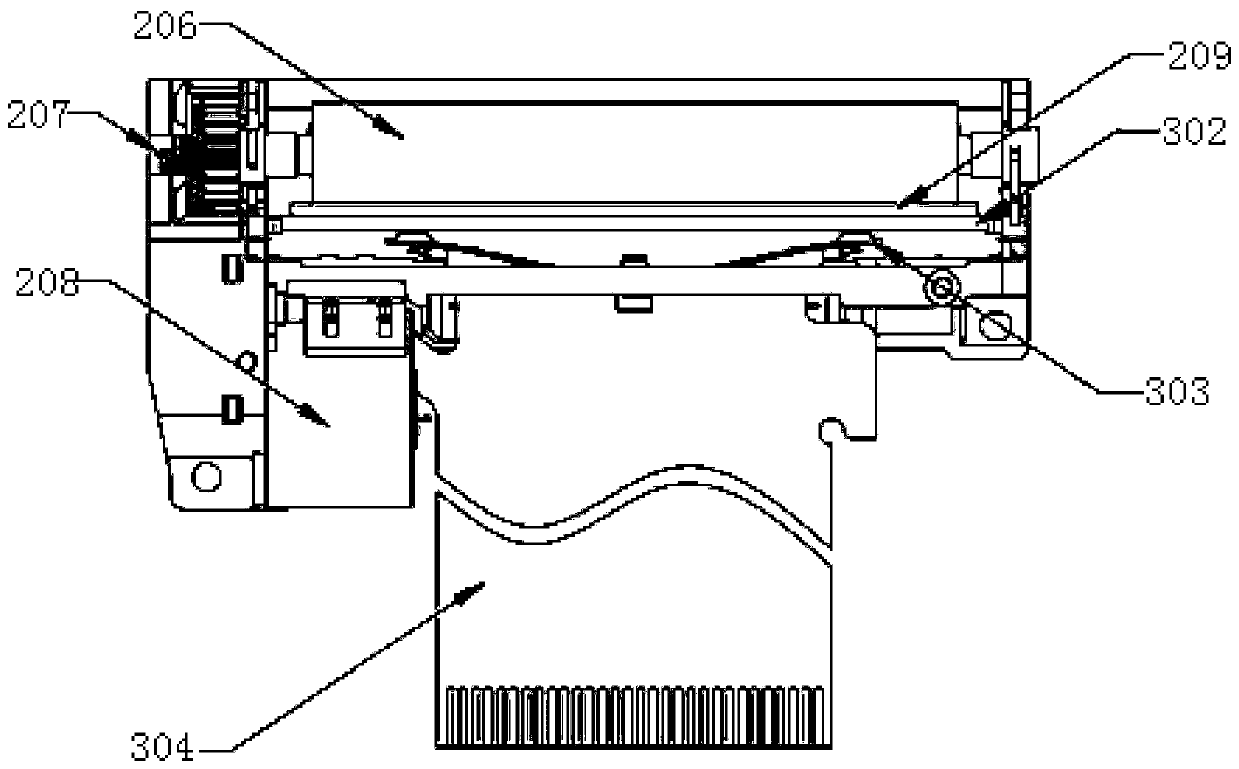

[0042] Specifically, refer to image 3 and Figure 4 , the movement includes a frame 205, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap