A kind of pretreatment method and system of lignocellulose prepared based on xylooligosaccharide

A lignocellulose and pretreatment technology, which is applied in the preparation of oligosaccharides and sugar derivatives, chemical instruments and methods, etc., can solve the problems of environmental protection cost, production cost impact, influence on the quality of xylo-oligosaccharides, etc., and achieves reaction energy consumption. The effect of reducing and improving mass transfer, heat transfer and catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

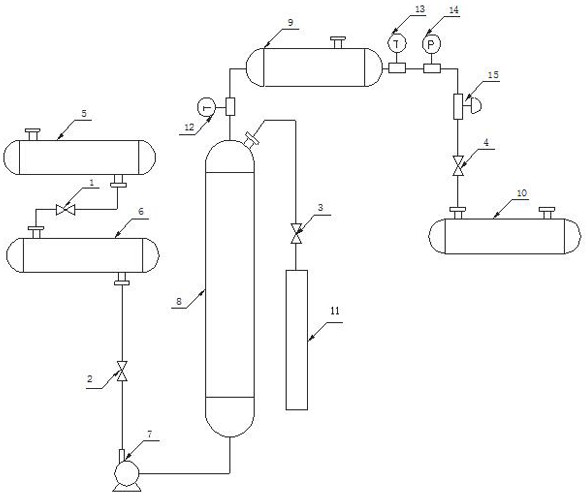

[0028] Put the corn cob into the storage tank 6 after being air-dried and crushed, open the valve 1, inject 1.3% aqueous solution of maleic acid and ethylene glycol compound catalyst from the storage tank 5 into the storage tank 6, and make a mixed slurry Material, the solid-liquid ratio is 1:15; close valve 1, open valve 2, start the feed pump 7 to make the mixed slurry enter the reactor 8, the feed flow rate is set to 600L / h, and react at 180 ° C; Open valve 3, rush into nitrogen from nitrogen tank 11 to maintain pressure at 2.5Mpa, and control by pressure control system 15; After mixed slurry flows out from reactor 8, then enters secondary reaction buffer tank 9, while reacting Open the valve 4 to inject the outflowing reaction liquid into the reaction liquid collection tank 10 . During the entire reaction process, the temperature controller a 12 and the temperature controller b 13 are responsible for controlling the temperature of the reactor 8 and the secondary reaction b...

Embodiment 2

[0030] Put corn stalks into storage tank 6 after being air-dried and pulverized, open valve 1, inject 4.5% aqueous solution of citric acid and ethanol composite catalyst from liquid storage tank 5 into storage tank 6, make mixed slurry, solid The liquid ratio is 1:10; close valve 1, open valve 2, start the feed pump 7 to make the mixed slurry enter the reactor 8, set the feed flow rate to 500L / h, and react at 135°C; open valve 3 at the same time , flush nitrogen from the nitrogen tank 11 to maintain the pressure at 3.3Mpa, and control it through the pressure control system 15; after the mixed slurry flows out of the reactor 8, it enters the secondary reaction buffer tank 9, and the valve 4 is opened while reacting , so that the flowing out reaction solution is injected into the reaction solution collection tank 10 . During the entire reaction process, the temperature controller a 12 and the temperature controller b 13 are responsible for controlling the temperature of the reac...

Embodiment 3

[0032] Put the wheat straw into the storage tank 6 after being air-dried and pulverized, open the valve 1, inject 6.6% aqueous solution of oxalic acid and propylene glycol compound green catalyst from the storage tank 5 into the storage tank 6, and make a mixed slurry, solid The liquid ratio is 1:7.5; close the valve 1, open the valve 2, start the feed pump 7 to make the mixed slurry enter the reactor 8, the feed flow rate is set to 3000L / h, at 300 o React under C; open valve 3 simultaneously, rush into nitrogen from nitrogen tank 11 to maintain pressure at 4.5Mpa, and control by pressure control system 15; After mixed slurry flows out from reactor 8, then enters secondary reaction buffer The tank 9 opens the valve 4 during the reaction, so that the outflowing reaction solution is injected into the reaction solution collection tank 10 . During the entire reaction process, the temperature controller a 12 and the temperature controller b 13 are responsible for controlling the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com