A kind of hybrid acrylic electrophoretic paint and preparation method thereof

A technology of electrophoretic coating and acrylic acid, applied in the direction of electrophoretic coating, coating, etc., can solve the problems of reducing coating performance, achieve the effect of avoiding pH increase, improving redox activity, and solving difficult dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of aniline oligomer / carbon nanotube composites

[0033]Put 1.84g (0.01mol) N-phenyl-p-phenylenediamine (ADPA) into the reaction flask, add 100mL acetone, 100mL water, 25mL concentrated hydrochloric acid, 0.18g (10wt%) multi-walled carbon nanotubes (MWCNT) , mix evenly with a high-speed homogenizer, place in an ice bath and stir until the temperature drops to 0°C, drop 2.28g of ammonium persulfate dissolved in 25mL of water into the reaction bottle within 30min, stir and react for 4h, and pump under reduced pressure Filter, wash with 0.6mol / L hydrochloric acid and suck dry, wash once with 300mL acetone. Back-dope with 500mL 0.5mol / L ammonia water, then wash with a large amount of water until neutral. The product was dried under reduced pressure in an oven at 40°C to obtain a purple-black solid powder.

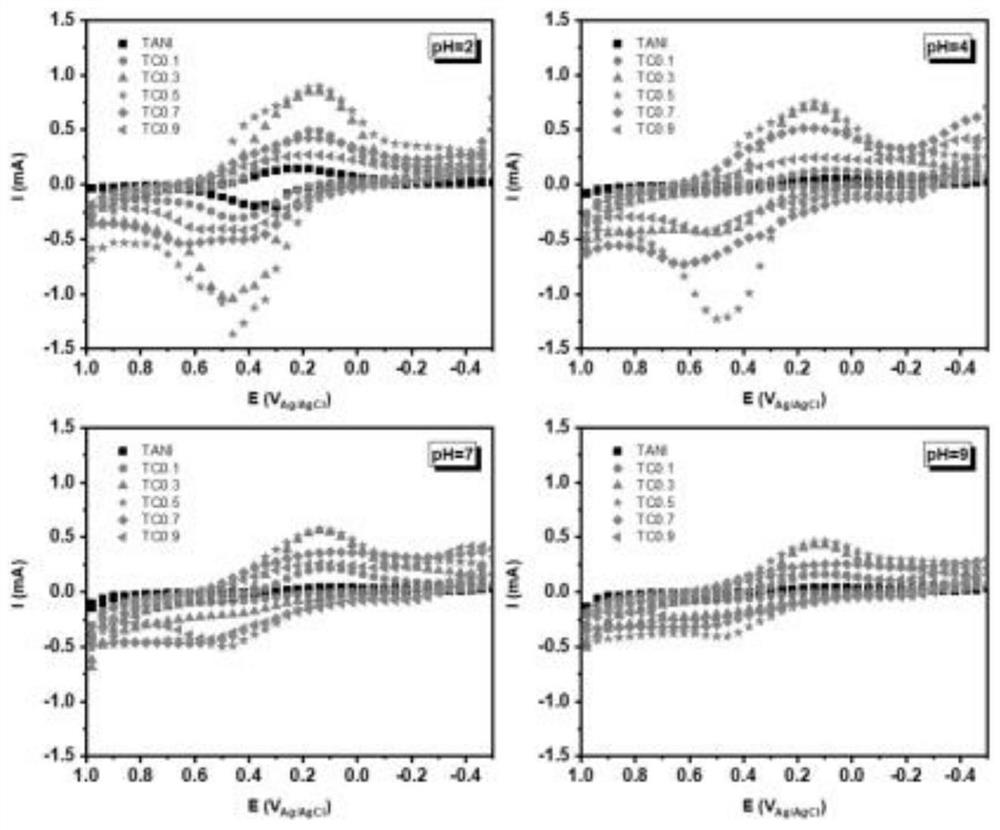

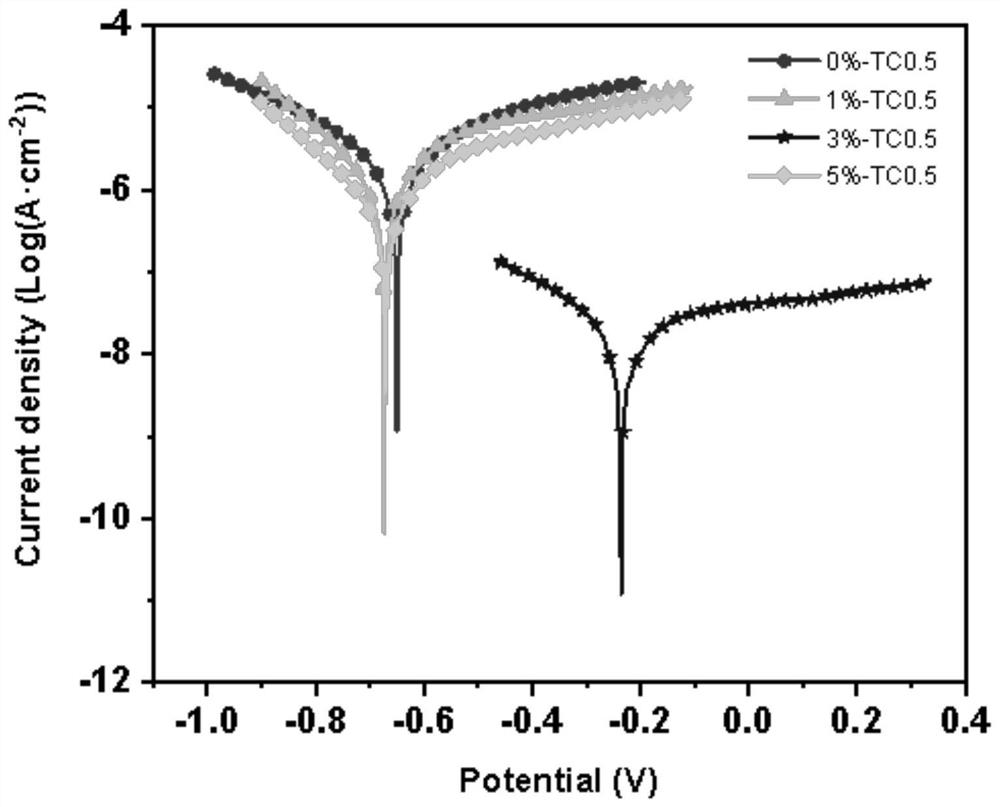

[0034] Its redox activity was studied by electrochemical workstation.

[0035] (2) Synthesis of acrylate copolymer

[0036] Add 50g of propylene glyco...

Embodiment 2

[0040] (1) Preparation of aniline oligomer / carbon nanotube composites

[0041] With embodiment 1.

[0042] (2) Synthesis of acrylate copolymer

[0043] With embodiment 1.

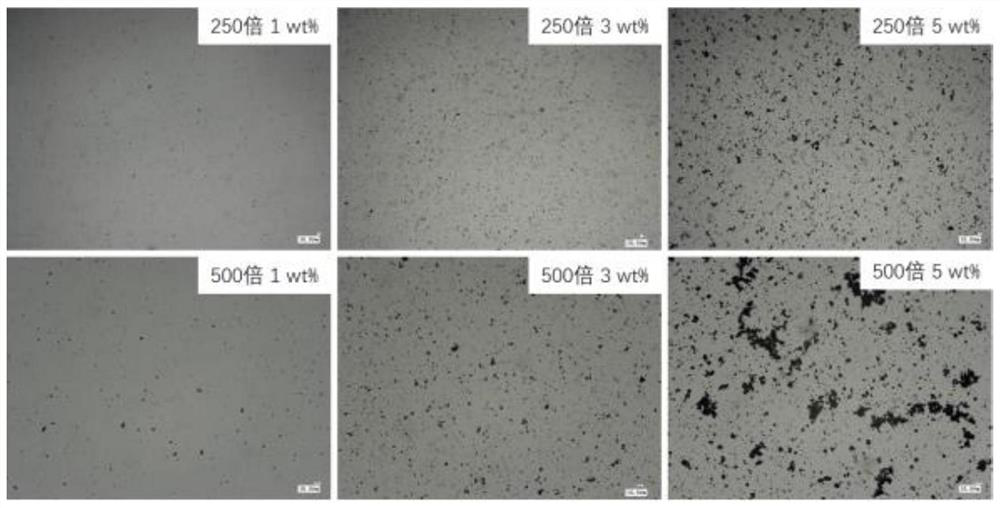

[0044] (3) Preparation of hybrid acrylic electrophoretic coating

[0045] Get step (1) gained aniline oligomer / carbon nanotube composite material 1.5g (3wt%) to add in the step (2) gained acrylate copolymer, high-speed homogenizer mixes evenly, and under agitation state with a certain speed to 200 g of deionized water was added dropwise to prepare a hybrid acrylic electrophoretic coating.

Embodiment 3

[0047] (1) Preparation of aniline oligomer / carbon nanotube composites

[0048] With embodiment 1.

[0049] (2) Synthesis of acrylate copolymer

[0050] With embodiment 1.

[0051] (3) Preparation of hybrid acrylic electrophoretic coating

[0052] Get step (1) gained aniline oligomer / carbon nanotube composite material 2.5g (5wt%) to add in step (2) gained acrylate copolymer, high-speed homogenizer mixes evenly, and under agitation state with a certain speed to 200 g of deionized water was added dropwise to prepare a hybrid acrylic electrophoretic coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com