Control method and device of electrolytic cleaning vertical tank liquid level at high-speed cleaning segment

A technology of electrolytic cleaning and cleaning section, which is applied in the field of steel rolling, which can solve the problems of low liquid level, no effective control means, and affecting the stable operation of the unit, and achieve the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

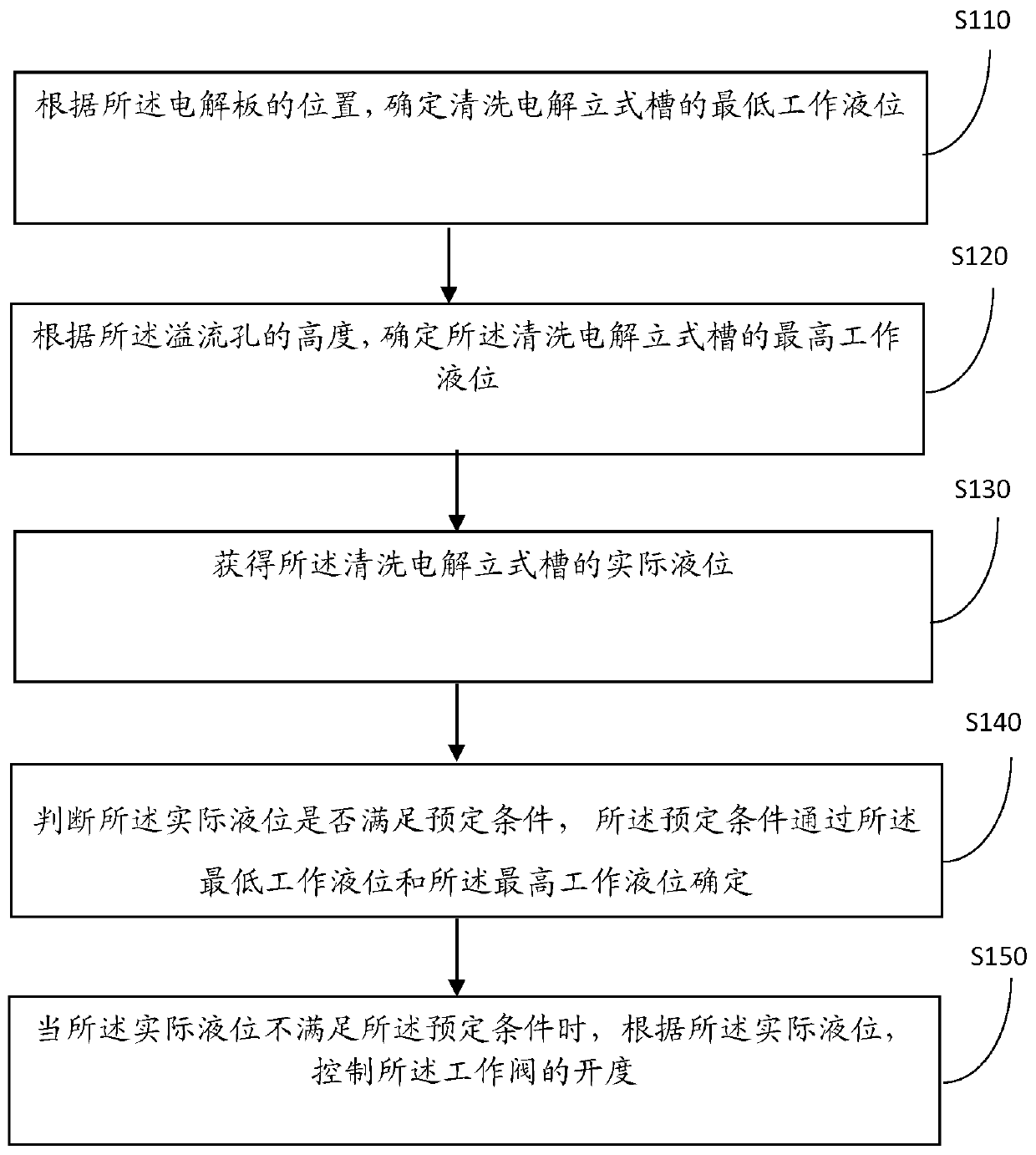

[0053] figure 1 It is a schematic flow chart of a liquid level control method for an electrolytic cleaning vertical tank in the high-speed cleaning section in an embodiment of the present invention. The embodiment of the present invention provides a method for controlling the liquid level of the electrolytic cleaning vertical tank in the high-speed cleaning section, such as figure 1 As shown, the method is applied to an electrolytic cleaning vertical tank liquid level control device, and the device includes an electrolytic plate, an overflow hole, and a normally open valve, and the normally open valve is arranged on the overflow pipe of the electrolytic cleaning vertical tank , the method includes:

[0054] Step 110: Determine the minimum working liquid level for cleaning the electrolytic vertical tank according to the position of the electrolytic plate.

[0055] Step 120: Determine the highest working liquid level of the cleaning electrolysis vertical tank according to the ...

Embodiment 2

[0074] In order to better introduce the effect of the liquid level control method of the electrolytic cleaning vertical tank in the high-speed cleaning section of the present invention, the application effect of the present invention will be described in detail below in conjunction with specific embodiments.

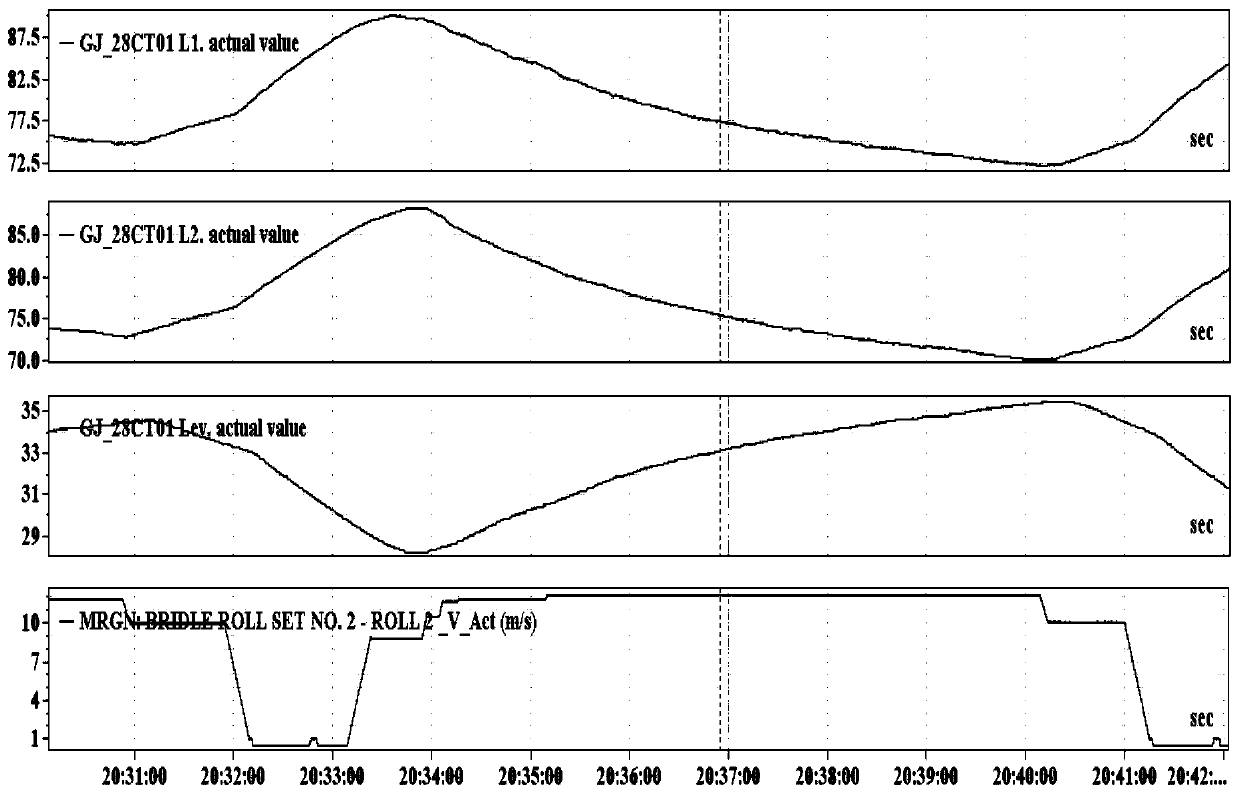

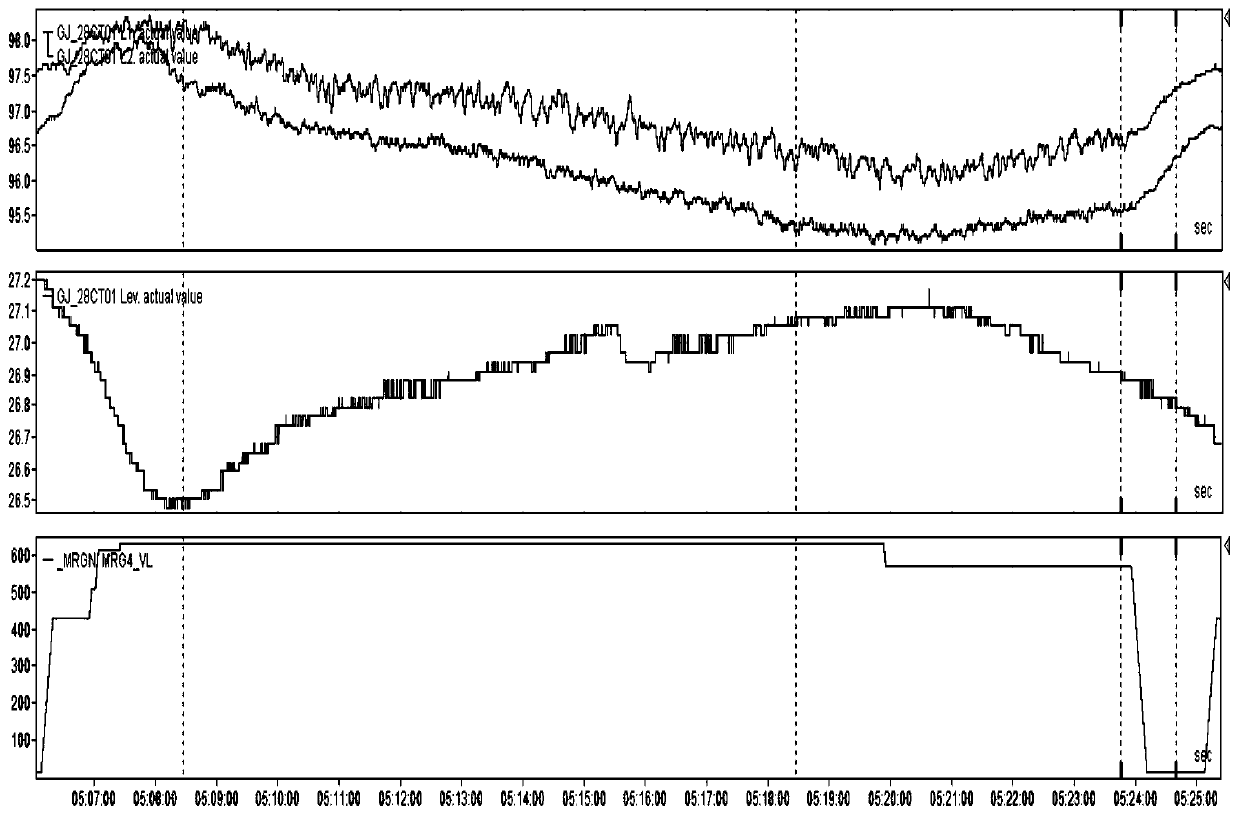

[0075] The electrolytic cleaning vertical tank liquid level control method of a kind of high-speed cleaning section of the present invention is applied in the 1420 units of A Iron and Steel Company, and the 1420 continuous retreat of A Iron and Steel Company is due to the current situation of electrolytic cleaning vertical tank liquid control as follows figure 2 As shown, as the speed of the cleaning section increases, the liquid level of the vertical tank gradually decreases; as the speed of the cleaning section decreases, the liquid level of the vertical tank gradually increases. The fluctuation of liquid level seriously affects the stable operation of the cleaning sec...

Embodiment 3

[0077] Based on the same inventive concept as the liquid level control method of the electrolytic cleaning vertical tank of the high-speed cleaning section in the foregoing embodiment, the present invention also provides a liquid level control device of the electrolytic cleaning vertical tank of the high-speed cleaning section, such as Figure 4 As shown, the device includes:

[0078] The first determining unit 11, the first determining unit 11 is used to determine the minimum working liquid level for cleaning the electrolytic vertical tank according to the position of the electrolytic plate;

[0079] The second determining unit 12, the second determining unit 12 is used to determine the highest working liquid level of the cleaning electrolytic vertical tank according to the height of the overflow hole;

[0080] A first obtaining unit 13, the first obtaining unit 13 is used to obtain the actual liquid level of the cleaning electrolytic vertical tank;

[0081] A first judging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com