Heel end anti-creeper

An anti-climber and stopper technology, applied in the field of rails, can solve the problems of affecting the axial fit of the fixing parts, cutting the fixing parts, increasing the cost, etc., and achieve the effects of improving the working conditions, reducing the stress, and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

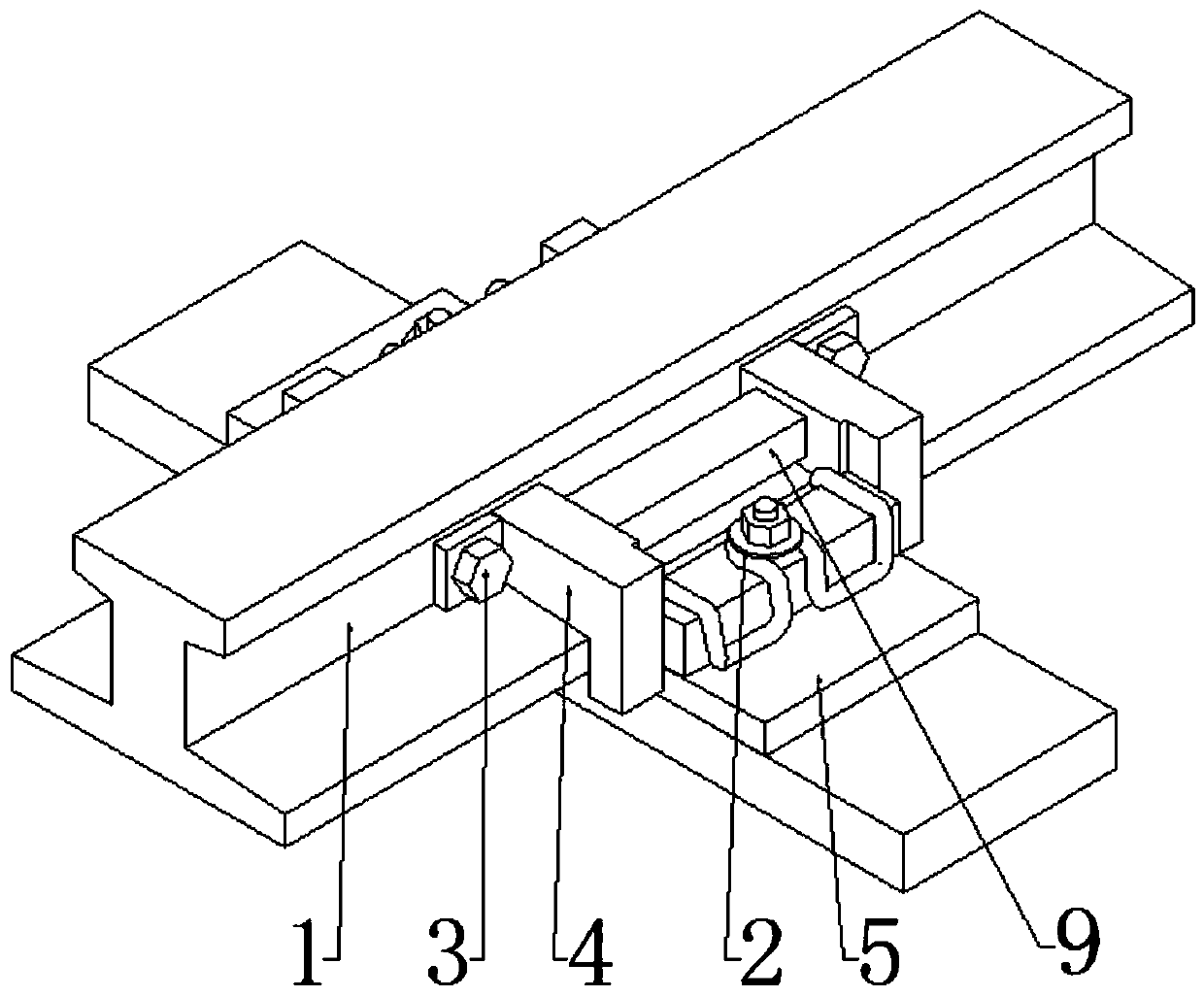

[0019] Such as Figure 1 to Figure 2 As shown, a heel anti-climbing device, the rail 1 is fixedly installed on the backing plate 5 through the fastener 2, and the backing plate 5 is connected with the switch sleeper through spike bolts, including the transverse bolt 3 and the limiter 4, There are two groups of stoppers 4, each group has two. The rail 1 is provided with a set of stoppers 4 on both sides of the backing plate 5, and each set of stoppers 4 is arranged symmetrically. Both sides of the rail 1 are connected by the transverse bolts 3 , and each limiter 4 abuts against the side of the corresponding backing plate 5 .

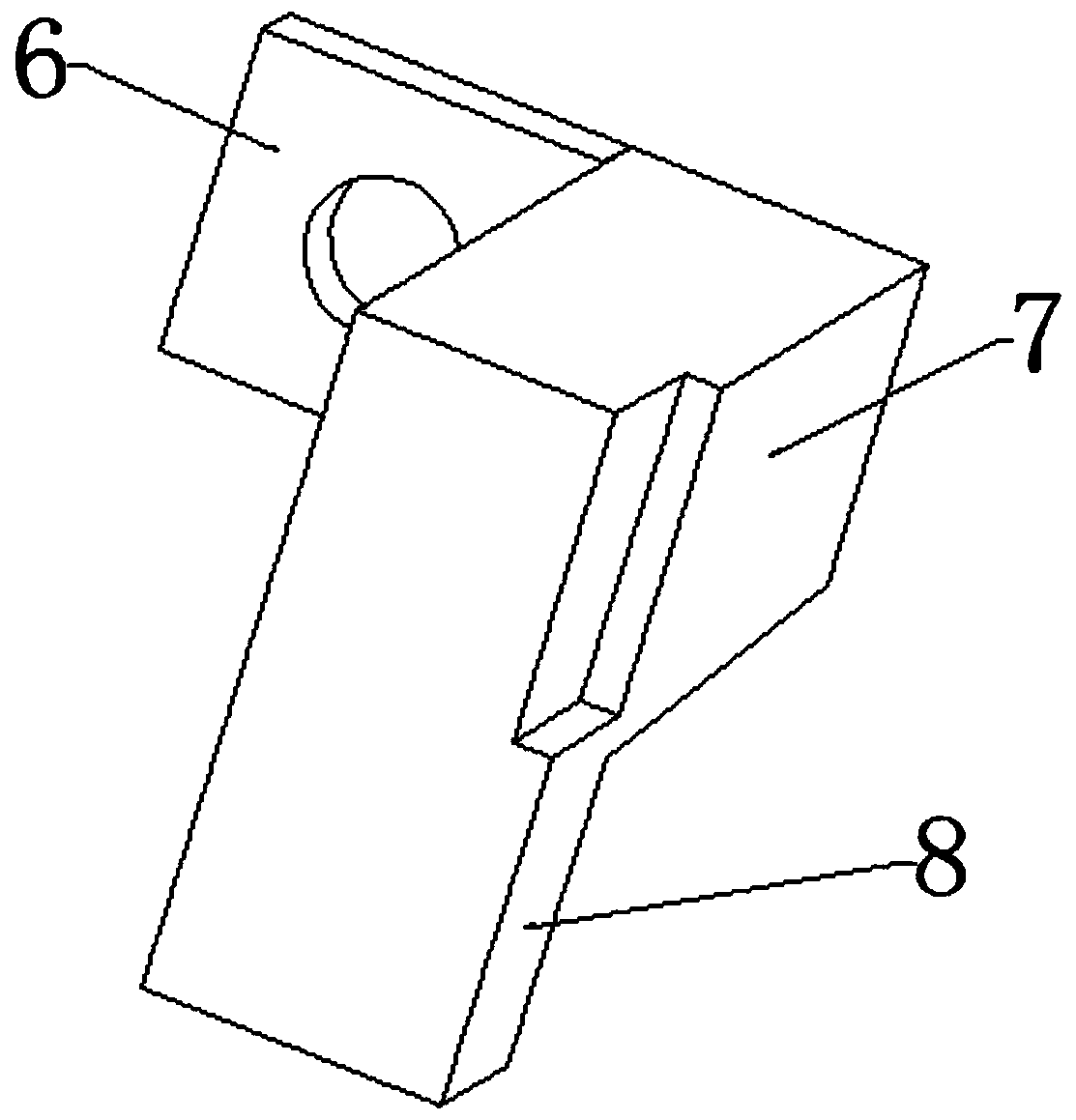

[0020] The limiter 4 includes a connecting plate 6, an intermediate body 7 and a limiting body 8, the outer side of one end of the intermediate body 7 is fixedly connected with the connecting plate 6, and the other end of the intermediate body 7 is fixedly connected with a The limiting body 8; the connecting plate 6 is provided with a through hole matche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com