A sticking tool for masking tape

A technology of masking paper and adhesive tape, which is applied in the direction of construction and building construction, etc., can solve the problems of small application range, low efficiency, and the inability to stick both sides of the gap at the same time, and achieve the effect of improving work efficiency and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

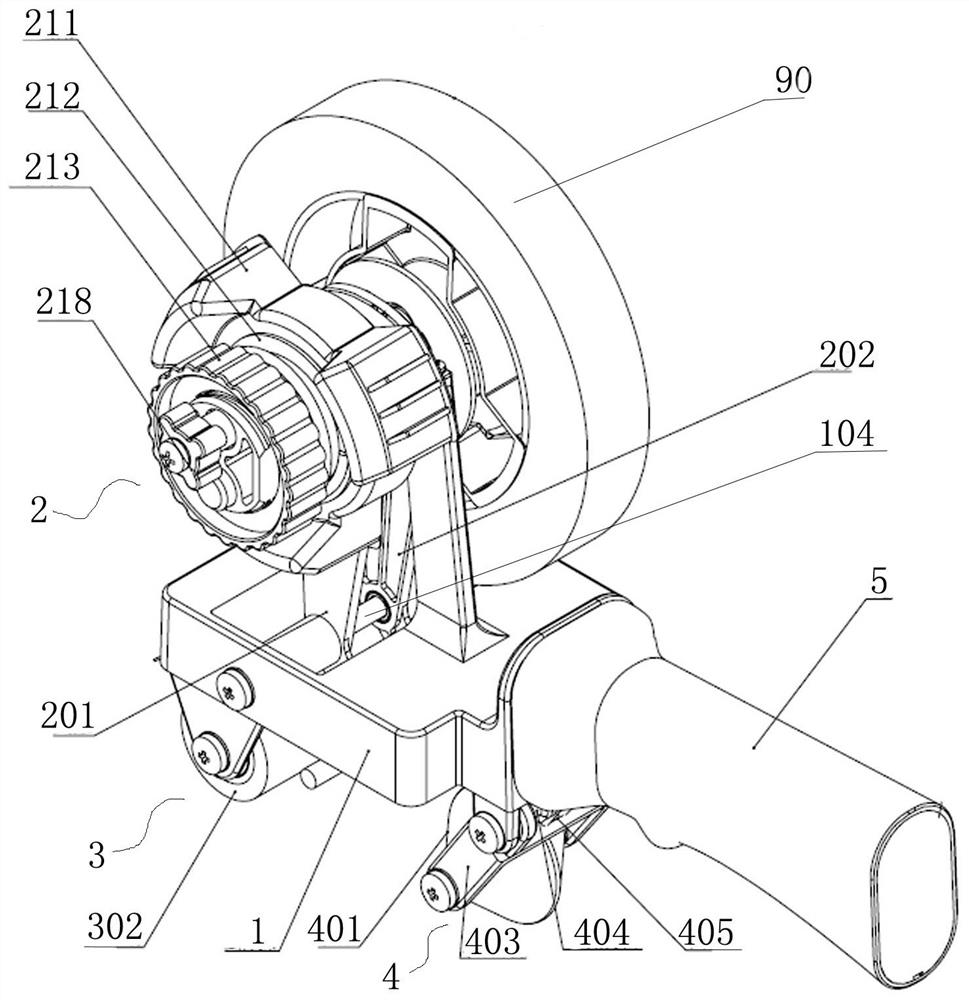

[0046] Such as Figure 1 to Figure 6 As shown, a pasting tool for masking tape, the pasting tool in this embodiment can be used for pasting on both sides of the gap, and the tape can be placed on both sides at the same time. Only one tape 90 is placed in the figure to show it.

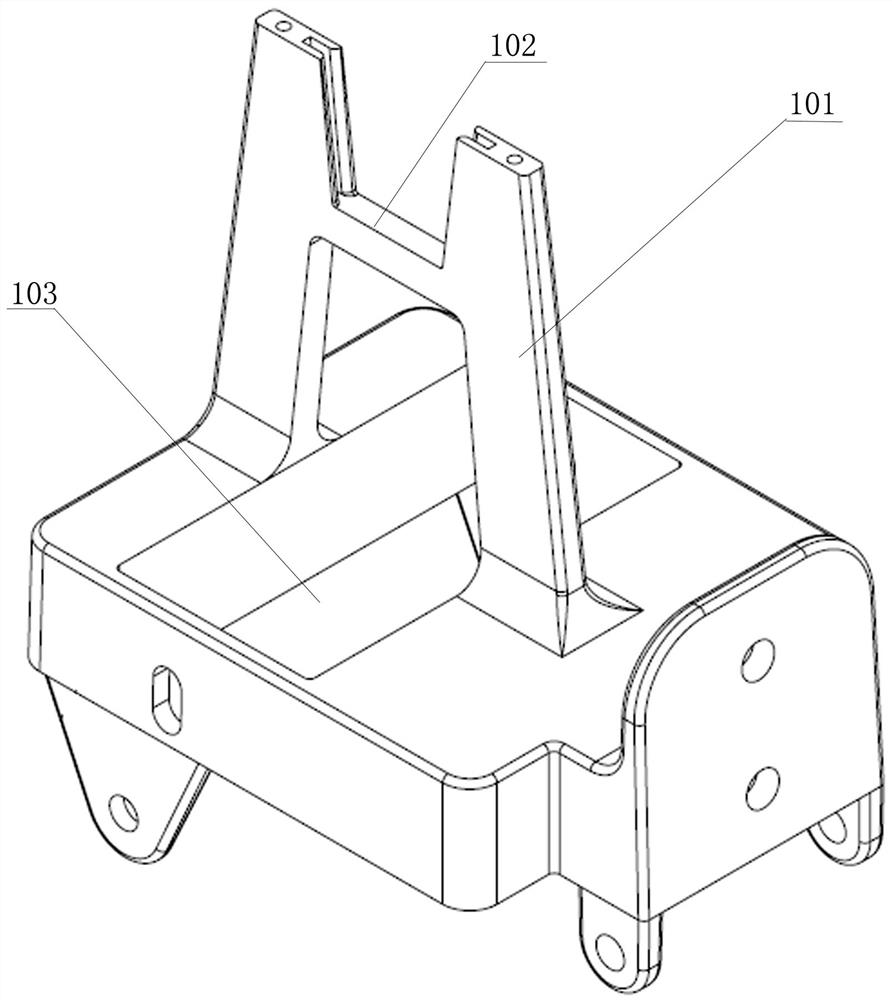

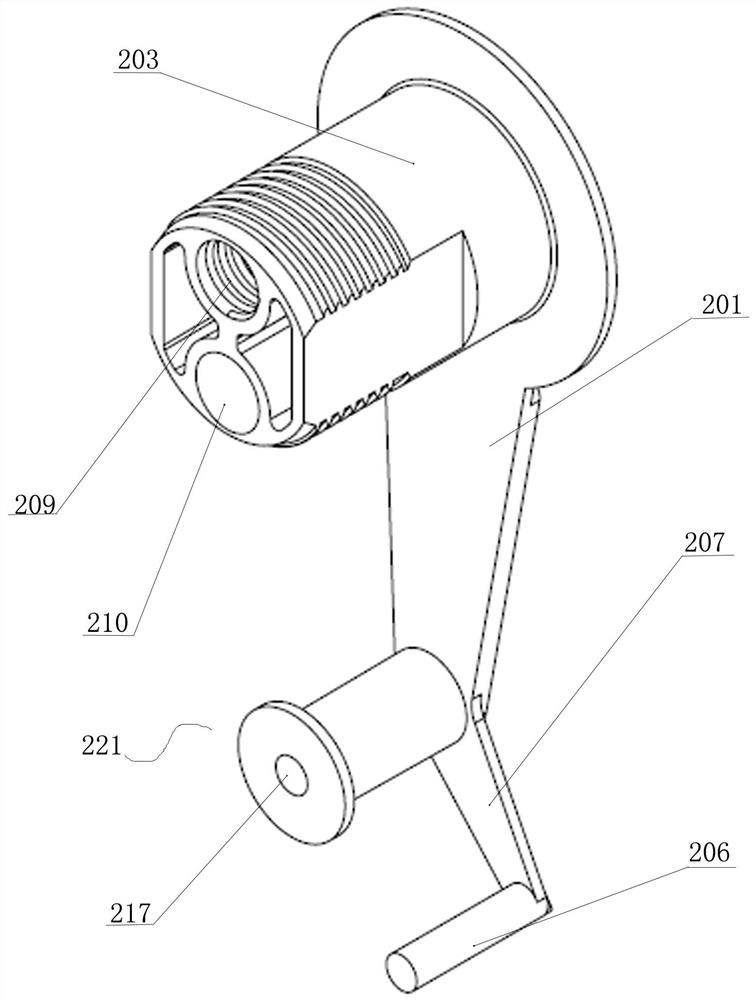

[0047] A sticking tool for masking tape includes a main body bracket 1, a tape rotating device arranged above the main body bracket 1, a pressing roller device 3 arranged at the lower front end of the main body bracket 1, and a tool guide arranged at the lower rear end of the main body bracket 1. In the device 4, the front end of the main body bracket 1 is provided with a knife saw 6 for cutting and pulling out multiple tapes, and the rear end of the main body bracket 1 is also provided with a handle 5.

[0048] The pressure roller device 3 includes a pressure roller shaft 301 and a pressure roller 302 sleeved on the pressure roller shaft 301. The pressure roller shaft 301 is connected to the main body suppo...

Embodiment 2

[0066] Such as Figure 7 to Figure 10 As shown, the difference between this embodiment and the first embodiment is that the guide device 4 is removed, the H-shaped support frame 101 in the first embodiment is replaced with a single-sided H-shaped support frame 9, and the main body frame of the first embodiment is replaced. 1 Replace with a single-sided main body bracket 8. The single-sided H-shaped support frame 9 is located on the side of the single-sided main body bracket 8. The pressure roller axial side under the single-sided H-shaped support frame 9 is provided for walking in the gap The guide disc 7 is arranged coaxially with the pressure roller and is locked and fixed on the single-side body support 8 by bolts and matching nuts. The guide disc 7 rotates synchronously with the pressure roller. This tool is applied to the gap of the single Side paste.

Embodiment 3

[0068] Such as Figure 11 to Figure 16 As shown, the difference between this embodiment and the first embodiment is that the axial adjustment mechanism is different. A rotating gear bracket 11 is added to the arm 102, so that the rotating gear rotates around the rotating gear bracket 11. The pasting tool in the embodiment is used for the masking tape to paste both sides of the gap.

[0069] The axial adjustment mechanism in this embodiment includes a guide structure and an adjustment structure. The adjustment structure includes a rotating rack axially arranged on a rotating column, and a rack hole is provided adjacent to the rotating rack. Further, the left rotating column is provided with a left Rotate the rack 12, the right rotation column is provided with a right rotation rack 13, the left rotation column and the right rotation rack 13 are provided with a left rack hole 17, and the right rotation rack 13 is inserted into the left In the rack hole 17 and cooperate with its guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com