Labeling machine and trash can with intelligent labeling function

A labeling machine and trash can technology, which is applied in the field of trash cans, can solve the problems of automatic separation of difficult labels and stickers, and achieve the effect of intelligent pasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

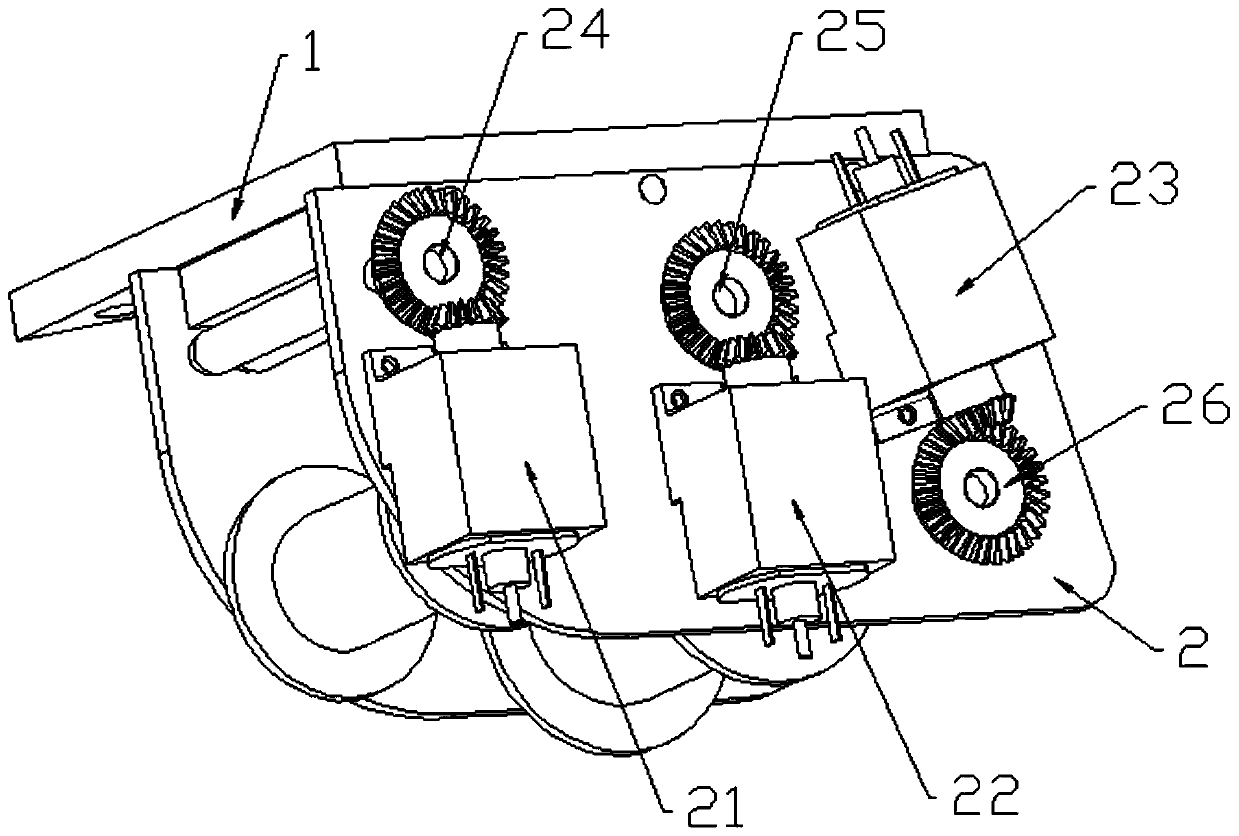

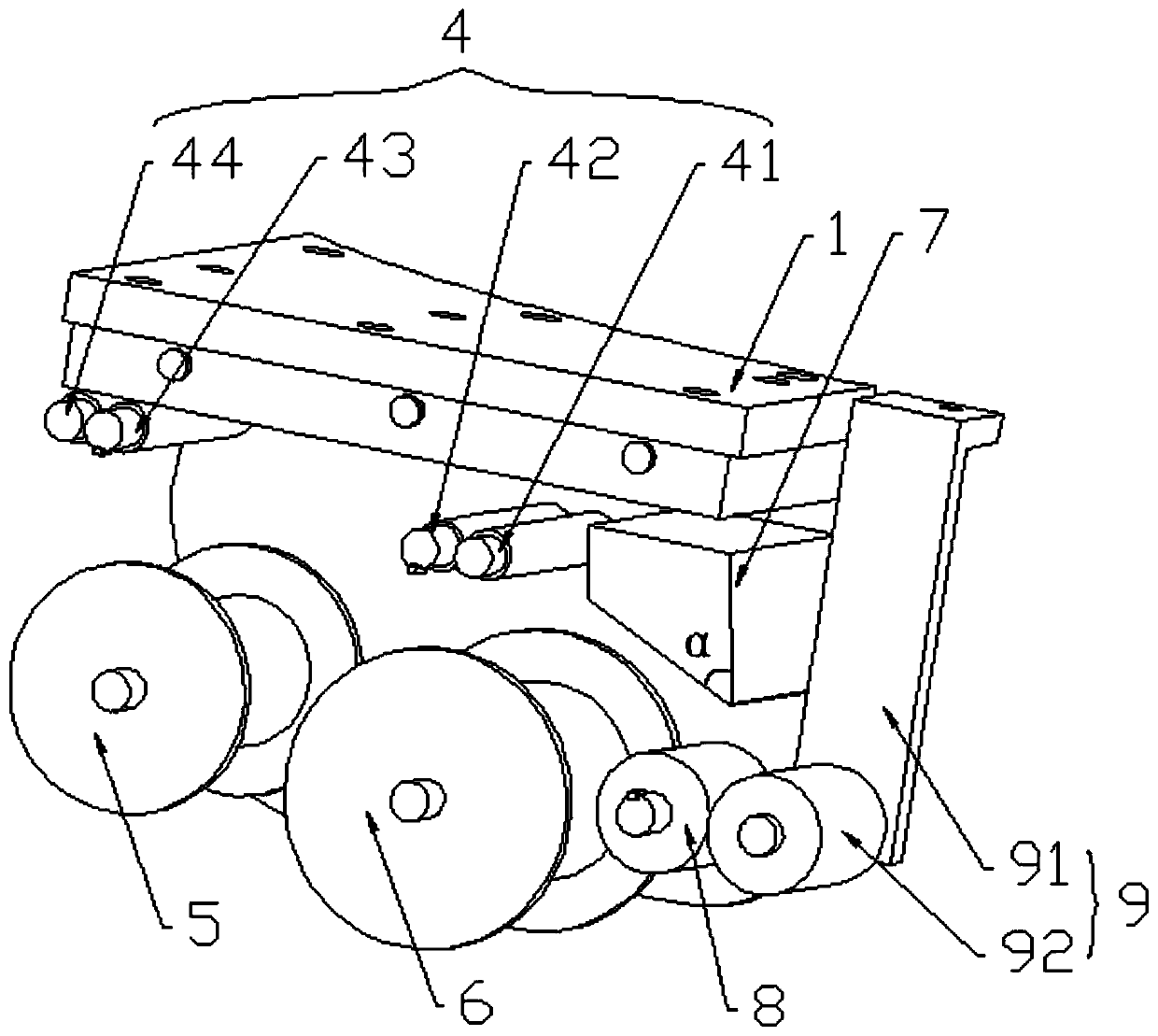

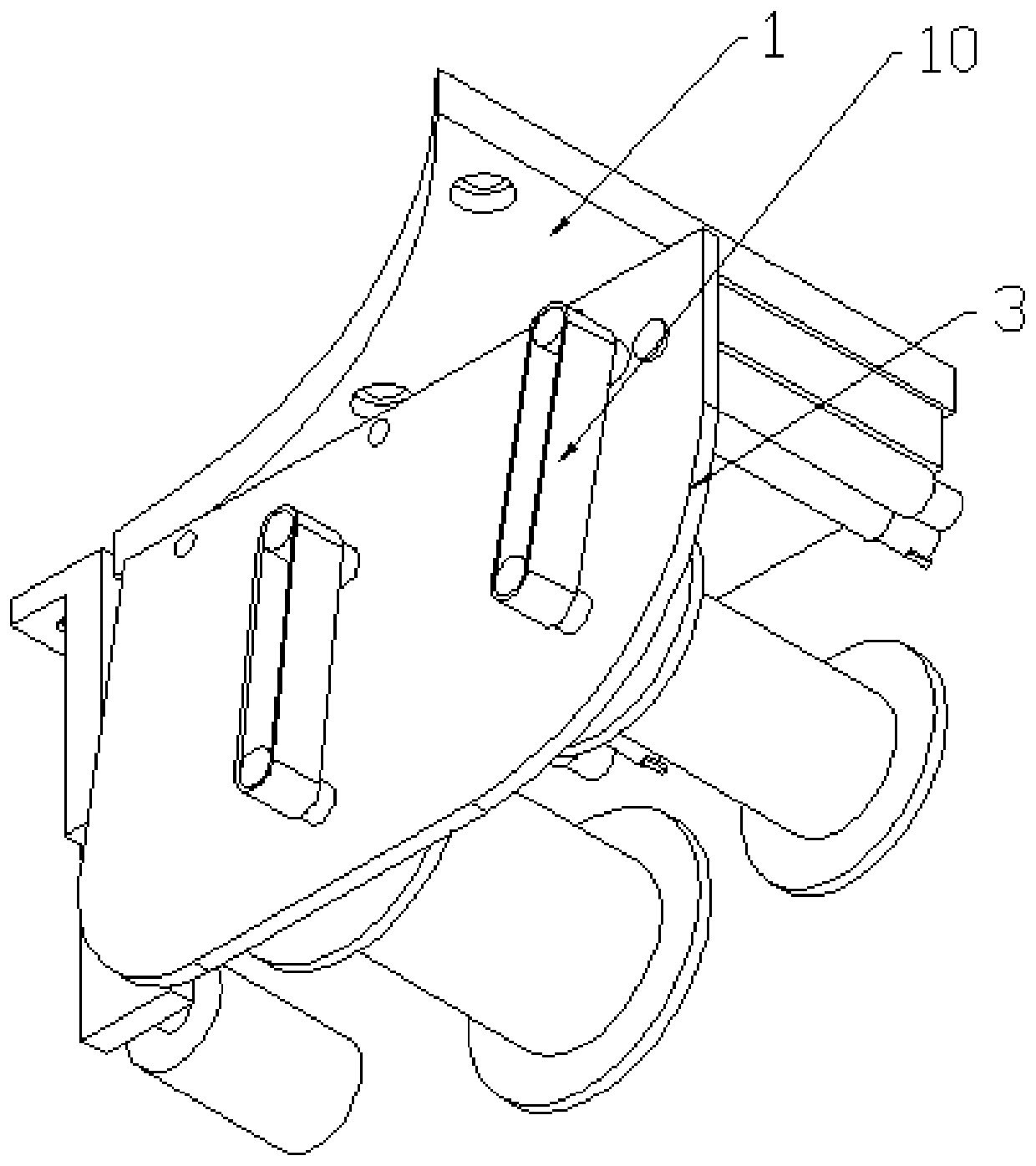

[0050] The invention provides a labeling machine, such as Figure 1-3 As shown, in this embodiment, it includes a top plate 1 and a first side plate 2 and a second side plate 3 arranged on both sides of the top plate 1, the first side plate 2 and the second side plate 3 are parallel and oppositely arranged, Between the first side plate 2 and the second side plate 3, there are label raw material bucket 6, waste paper recycling bucket 5, and drum assembly 4 vertically, and both ends of the label raw material bucket 6 and waste paper recycling bucket 5 are fixed by bearing seats On the first side plate 2 and the second side plate 3, the label raw material barrel 6 and the waste paper recycling barrel 5 can rotate around their axes respectively; The sensitive printing mechanism 7; the drum assembly 4 includes a first drum 41 and a second drum 43, and the two ends of the first drum 41 and the second drum 43 are fixed on the first side plate 2 and the first side plate 2 through anot...

Embodiment 2

[0061] On the basis of Embodiment 1, the present invention provides a trash can that can be intelligently labeled, such as Figure 5-12 As shown, it comprises a barrel body 101, a first roller 102, a second roller 103 and two setting wheels 104, and the setting wheels 104 are all arranged in parallel with the first roller 102 and the second roller 103. A frame shell is provided, and garbage bag films are wound on the first roller 102 and the second roller 103 , and the first roller 102 and the second roller 103 are respectively placed in the first placement frame 132 and the second placement frame 133 . The staving 101 is made up of a first semi-cylindrical staving 117 and a second semi-cylindrical staving 118, the diameter of the first semi-cylindrical staving 117 is greater than the diameter of the second semi-cylindrical staving 118, the first semi-cylindrical staving The top of the staving 117 and the second semi-cylindrical staving 118 is provided with a slide rail 119, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com