Flue butterfly valve for achieving flue gas emission zero leakage

A flue gas emission and zero-leakage technology, which is applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of complex flue gas components, high maintenance costs, and inconvenient production, and achieve the effect of reliably cutting off flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

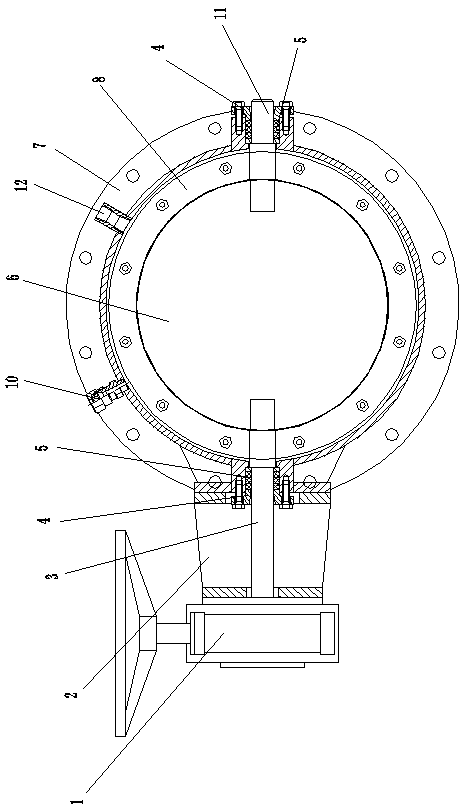

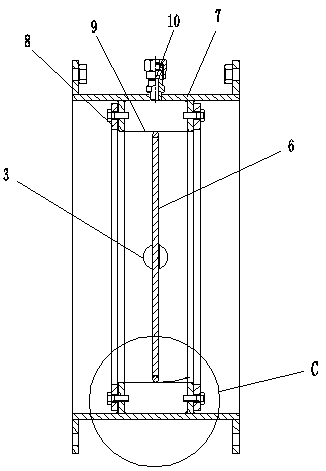

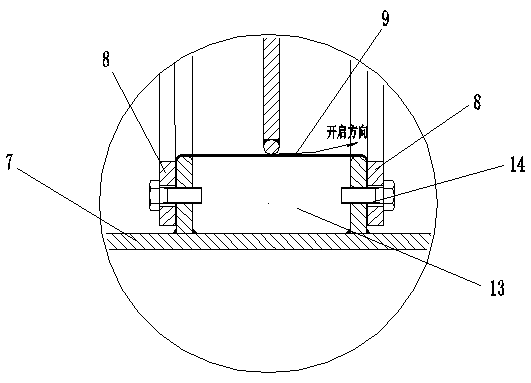

[0022] The technical solutions of the present invention will be further clearly and completely described below in conjunction with the accompanying drawings and embodiments.

[0023] See attached Figure 1-3 In the butterfly valve, the operating mechanism 1 installed at the end of the bracket 2 is connected to the front half shaft 3 mounted on the bracket 2, and the two ends of the butterfly plate 6 in the valve body 7 are respectively connected to the front half shaft 3 and the rear half shaft 11. Connection, the sealing packing 5 is installed between the valve body 7 and the front half shaft 3 and the rear half shaft 11, and it is tightly covered with the packing gland 4. The upper and lower ends of the valve body 7 are respectively equipped with a pressure ring 8, and the pressure ring 8 is stretched. Fluorine plastic cloth 9 forms a hollow cylinder, and the disc plate 6 is installed in the cylinder formed by fluorine plastic cloth 9. The pressure rings 8 at both ends are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com