A pressure cut-off device controlled by a solenoid valve

A technology of cut-off device and solenoid valve, applied in the direction of fluid pressure actuating device, safety device, fluid pressure actuating system components, etc. Small, overall size reduction, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

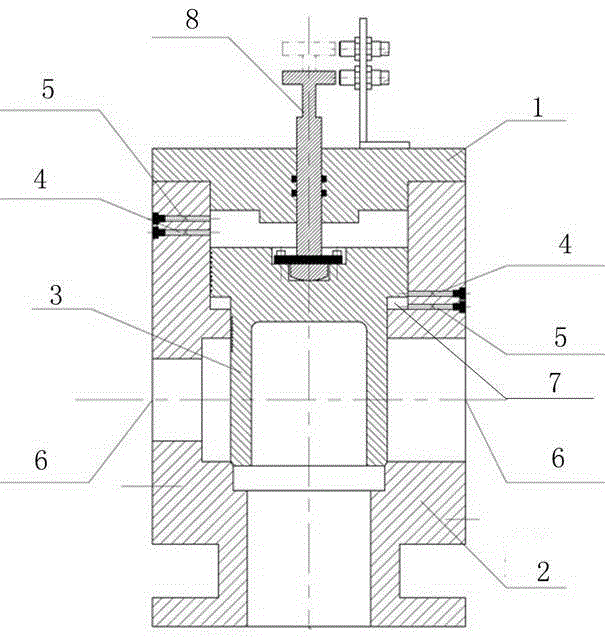

[0025] A pressure cut-off device whose opening and closing is controlled by a solenoid valve, including a housing, a piston, a cover plate, and a solenoid valve; The cover plate is used to control the on and off of the hydraulic oil; the piston is assembled in the housing to divide the housing into a pressure oil chamber, an oil outlet chamber, an oil return chamber and a control oil chamber. There are control oil port and buffer oil port on the housing, the control oil port on the control oil chamber housing is located above the buffer oil port, the control oil port on the oil return chamber housing is located below the buffer oil port, the control oil There are throttle holes in both the control oil port and the buffer oil port, and the diameter of the throttle hole in the control oil port is larger than the diameter of the throttle hole in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com