A product image detection method and comparison device capable of automatic light distribution

An image detection and light distribution technology, which is applied in the direction of measuring devices, optical devices, and optical testing of defects/defects, can solve problems such as low reliability and slow recognition speed, and achieve automatic processes, uniform illumination, and improved detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

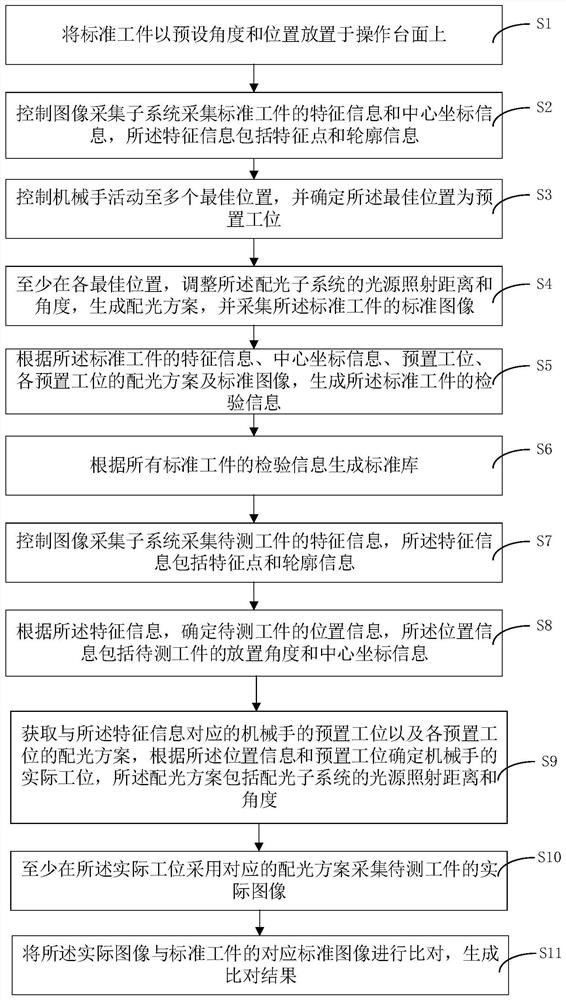

[0066] Please refer to figure 1 As shown, the embodiment of the present invention provides a product image detection method with automatic light distribution, which is applied to a manipulator. The manipulator includes an image acquisition subsystem and a light distribution subsystem. The wrist at the end of the arm, the image acquisition subsystem and the photodistribution subsystem are arranged on the wrist, and the method includes:

[0067] S1, place the standard workpiece on the operating table at a preset angle and position.

[0068] The standard workpiece is used to provide inspection information for subsequent workpieces with the same feature information. In this embodiment, the operating platform can be a conveyor belt or a fixed platform.

[0069] S2. Control the image acquisition subsystem to acquire feature information and center coordinate information of the standard workpiece, where the feature information includes feature points and contour information.

[0070...

no. 2 example

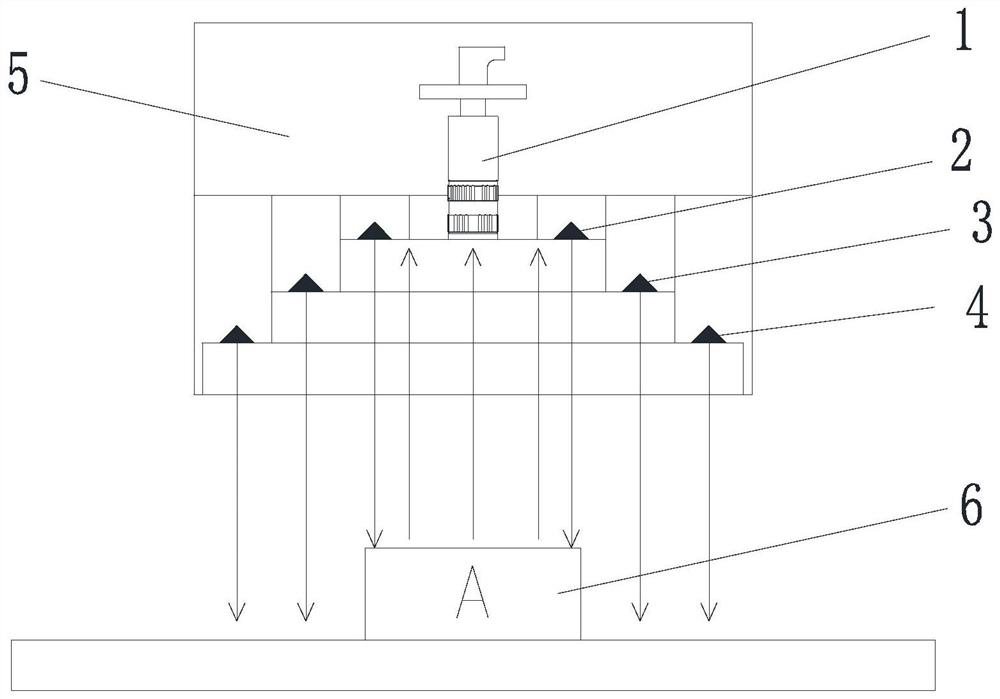

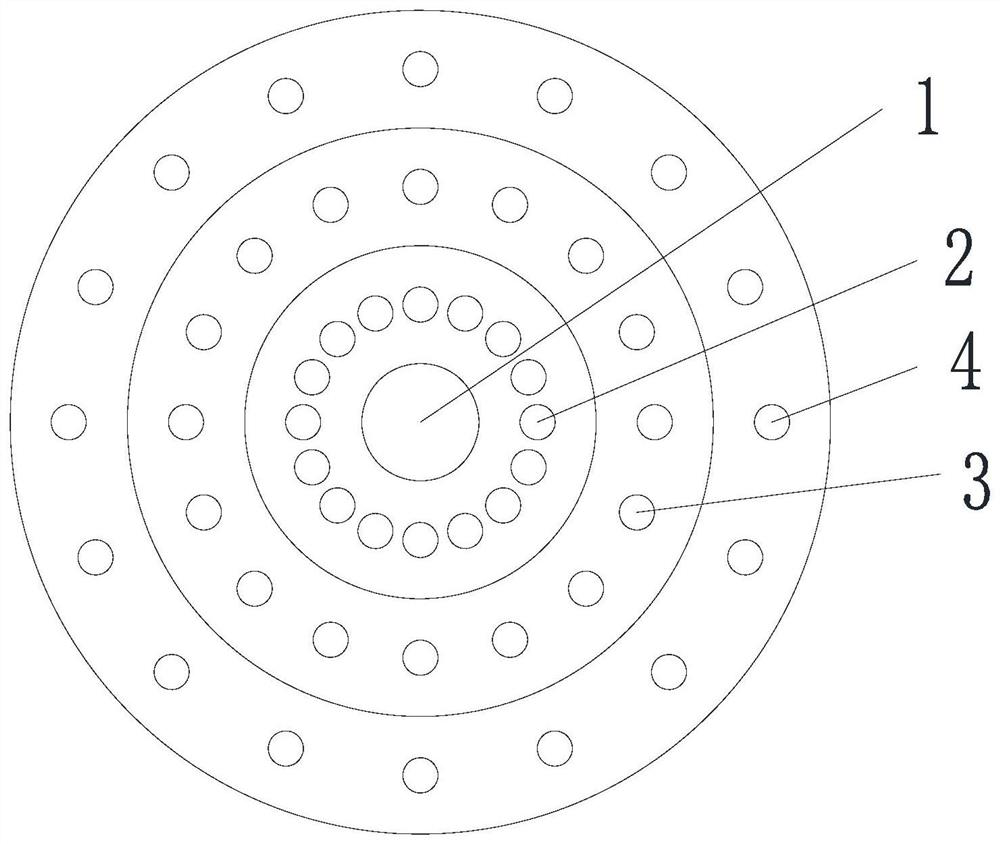

[0120] An embodiment of the present invention provides a product image detection device capable of automatic light distribution, which is applied to a manipulator. The manipulator includes an image acquisition subsystem and a light distribution subsystem. The manipulator also includes a three-coordinate manipulator and a The wrist, the image acquisition subsystem and the light distribution subsystem are arranged on the wrist, and the light distribution subsystem includes at least a first ring light source and a second ring light source arranged from the inside to the outside with the image acquisition subsystem as the center and a third ring light.

[0121] Please refer to Figure 6 , the detection device includes:

[0122] The control module 110 is connected with the determination module 120, and is used to control the image acquisition subsystem to acquire feature information of the workpiece to be measured, the feature information including feature points and contour infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com