Reinforcing structure of anti-falling-type indication pile base

A technology for strengthening structures and marking piles, which is applied in the direction of marking, display devices, instruments, etc., can solve problems such as knockdown, tilting, small area, etc., and achieve high connection strength and ideal anti-fall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

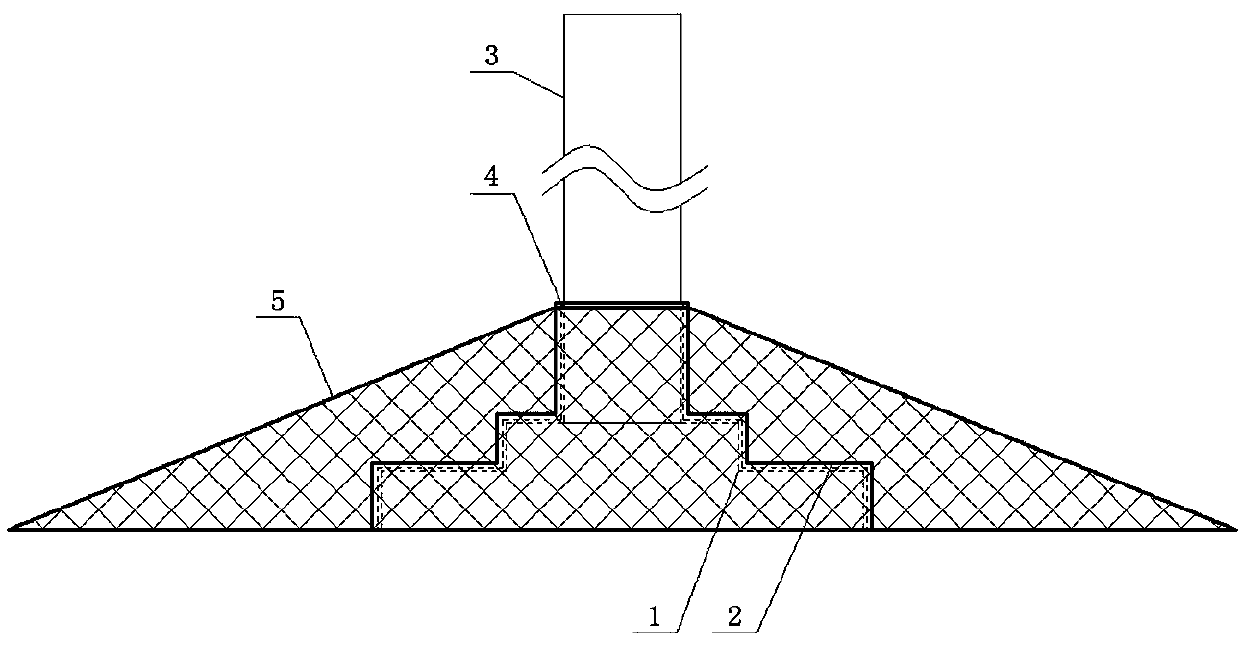

[0030] Such as figure 1 As shown, an anti-falling type marking pile base reinforcement structure includes a base sleeve 2 whose shape matches the marking pile base 1 and is used to cover the marking pile base 1. The top of the base sleeve 2 is opened to allow the marking The perforation 4 pierced by the pile part 3, the base sleeve 2 is provided with a hollow and flat grid plate cover 5, and the grid plate cover 5 covers the base sleeve 2 inside.

[0031] The grid plate cover 5 and the base sleeve 2 are integrally formed.

[0032] In this embodiment, the connection structure between the grid plate cover and the base sleeve can adopt an integrated molding structure according to different materials. When both the grid plate cover and the base sleeve are made of plastic parts, it can be made by integral plastic molding technology. Integral molding structure, when both the grid plate cover and the base sleeve are made of concrete parts, the integrated casting technology can be us...

Embodiment 2

[0034] The difference from Embodiment 1 is that the grid plate cover 5 and the base sleeve 2 are connected by an assembled structure.

[0035] The assembled structure adopted between the grid plate cover 5 and the base sleeve 2 is a bolt and nut assembly connection structure, that is, an extension part is arranged on the grid plate cover and the base sleeve, and between the two extension parts Connections are made by bolt and nut assemblies.

[0036] In this embodiment, the bolt and nut assembly connection structure is used to realize the assembled structure design between the grid plate cover and the base sleeve. Of course, the hook and ring connection structure or the screw connection structure can also be used to achieve the same effect; when using When the hook and ring connection structure is used, a hook / hanging ring is set on the grid plate cover and a hanging ring / hook matching the hook is set on the base sleeve. The internal thread is provided, and the external threa...

Embodiment 3

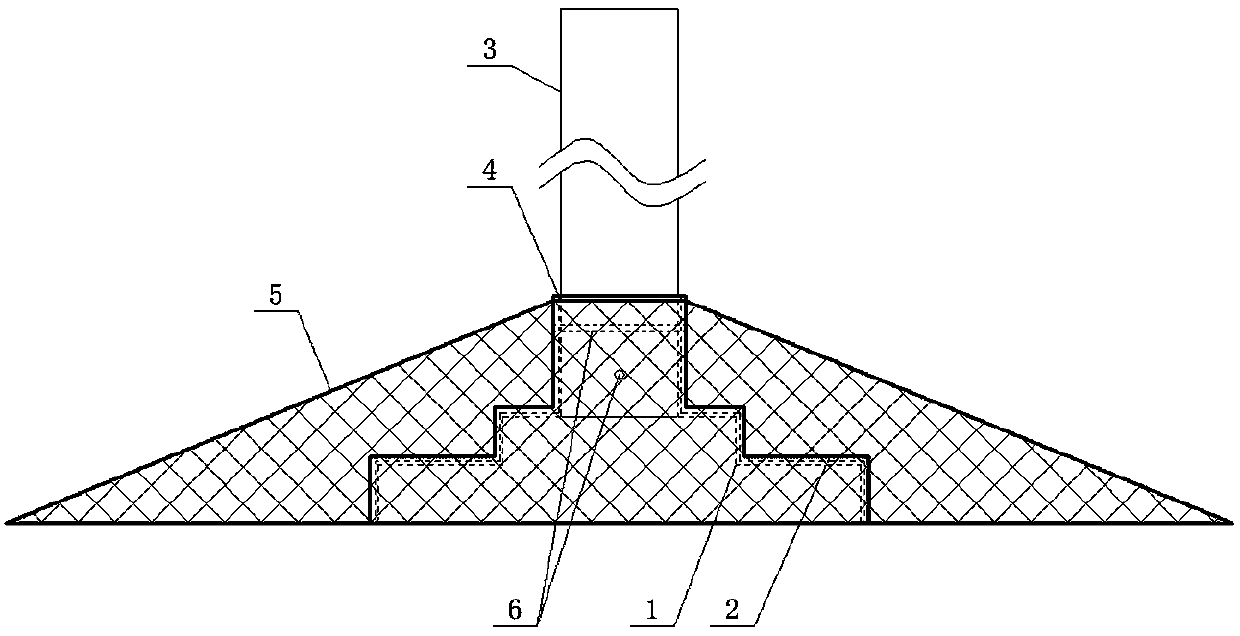

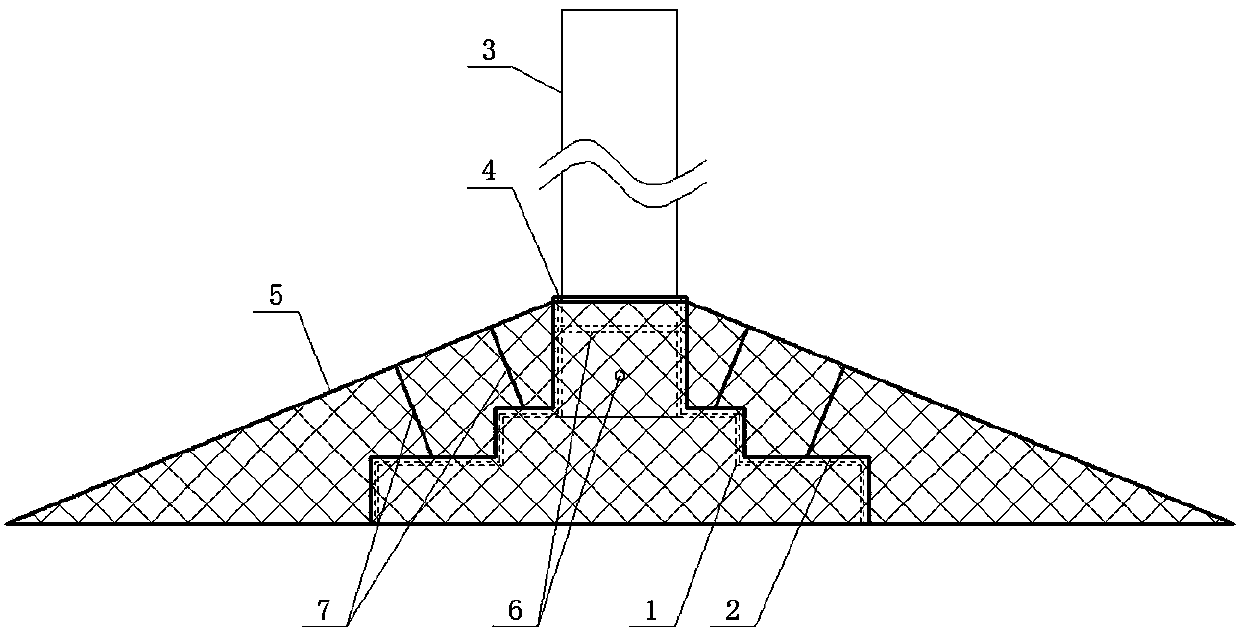

[0038] Such as figure 2 As shown, an anti-falling type marking pile base reinforcement structure includes a base sleeve 2 whose shape matches the marking pile base 1 and is used to cover the marking pile base 1. The top of the base sleeve 2 is opened to allow the marking The perforation 4 pierced by the pile part 3, the base sleeve 2 is provided with a hollow and flat grid plate cover 5, and the grid plate cover 5 covers the base sleeve 2 inside.

[0039] The grid plate cover 5 and the base sleeve 2 are integrally formed.

[0040] An insertion hole 6 is horizontally opened on the base sleeve 2 .

[0041] The number of the jacks 6 is 2 which are spatially staggered.

[0042] When the marking pile has no base, use a drilling rig to drill a through hole that matches the socket 6 on the marking pile, and use the fixing rod to penetrate the socket 6 and the through hole in order to fix the marking pile on the base cover Inside barrel 2.

[0043] Both the base sleeve 2 and the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com