A Lithium Iron Phosphate Lithium Polymer Lithium Battery Capable of High Current Charge and Discharge

A lithium iron phosphate, charging and discharging technology, applied in battery electrodes, secondary batteries, battery pack components and other directions, can solve the problems of insufficient high current discharge capacity, poor high temperature resistance, easy flatulence failure, etc. Charge and over-discharge and high temperature resistance, improve over-discharge resistance, reduce the effect of internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

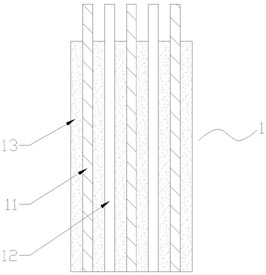

[0013] like figure 1 As shown, in this embodiment, the present invention includes a battery core 1, a battery casing wrapped outside the battery core 1, and an electrolyte filled inside the battery casing. The battery core 1 adopts Laminate structure, including a plurality of stacked positive electrode sheets 11 and negative electrode sheets 12, and each of the negative electrode sheets 12 is located between two adjacent positive electrode sheets 11, and the adjacent positive electrode sheets 11 and negative electrode sheets A separator 13 is arranged between 12, the positive electrode sheet 11 is formed by coating the positive electrode slurry on the positive electrode current collector, and the negative electrode sheet 12 is formed by coating the negative electrode slurry on the negative electrode current collector. In this design, the battery core 1 adopts a lamination structure, which increases the current channel and reduces the internal resistance of the battery.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com