Automatic aluminium scrap removing device for cylinder cover finished product

A technology of a rotating device and a driving device, applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., which can solve the problems that aluminum chips cannot be removed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

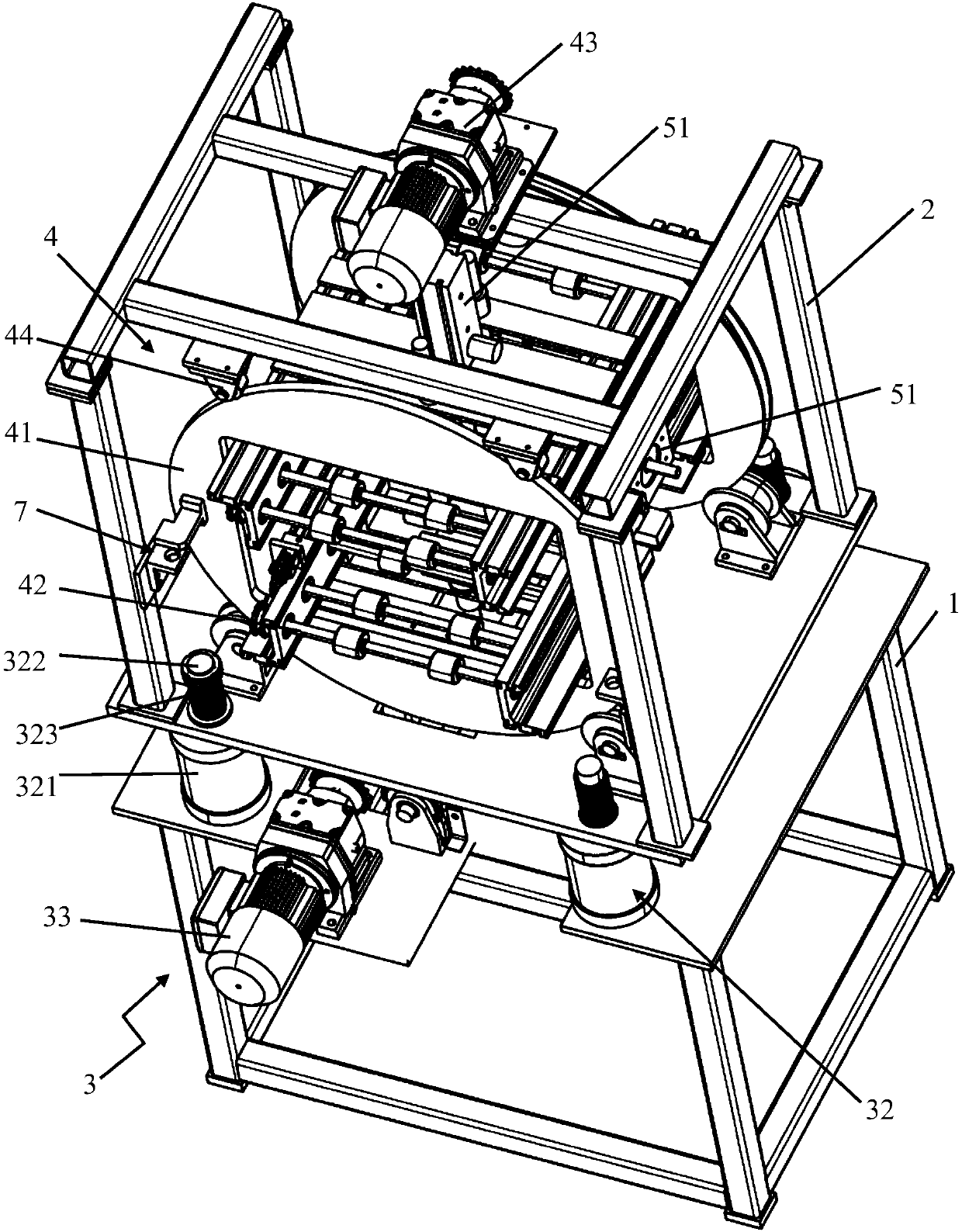

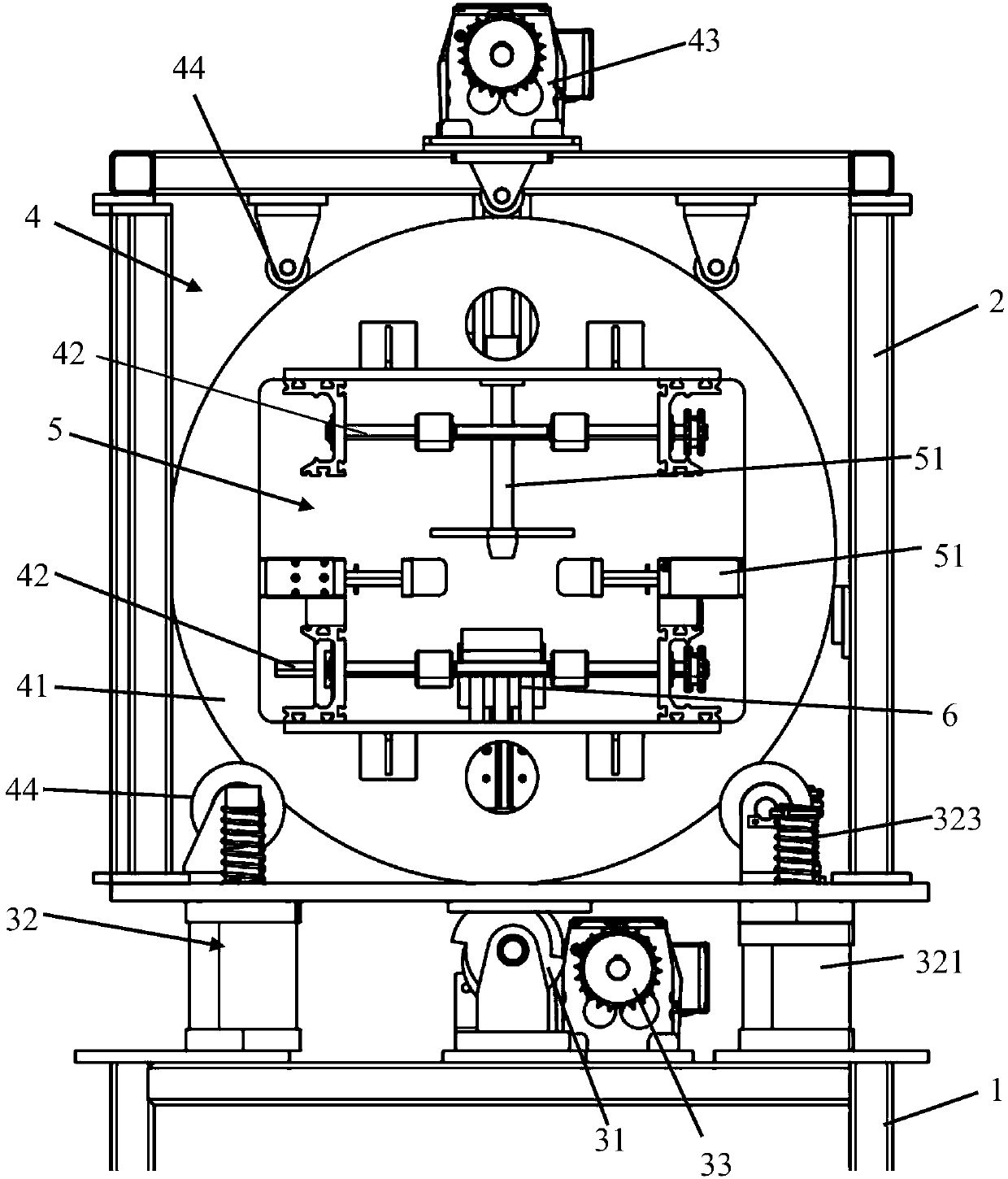

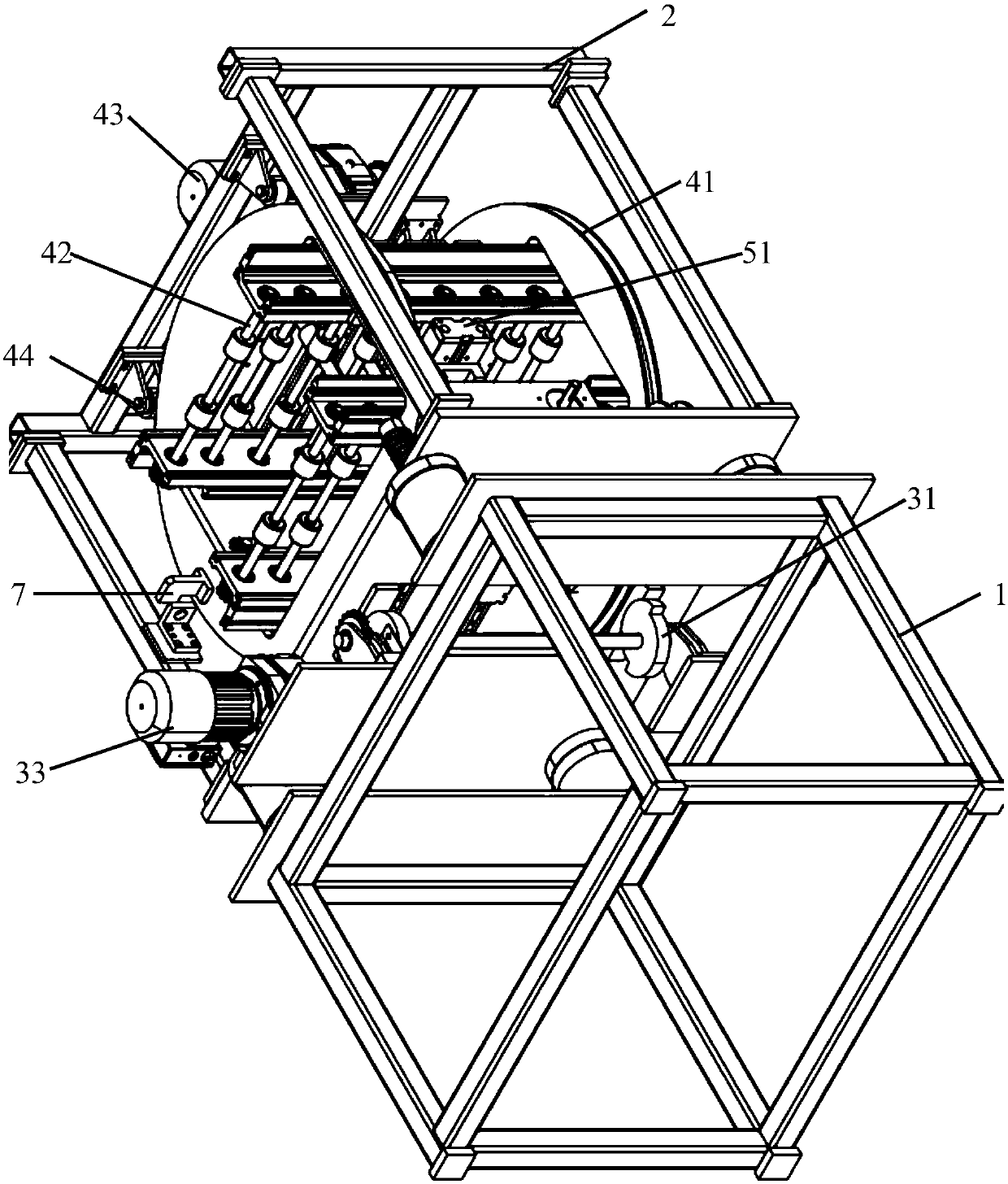

[0022] The following with attached Figure 1 to Figure 3 A device for automatically removing aluminum chips from finished cylinder head products of the present invention will be further described in detail.

[0023] A kind of automatic aluminum chip removal device for cylinder head finished products of the present invention, please refer to Figure 1 to Figure 3 Relevant figures include a first support 1, a second support 2, a cam oscillation mechanism 3, a rotating device 4 and a clamping mechanism 5. The cam oscillation mechanism 3 is vibrated up and down on the first support 1 and the second support. Between the two brackets 2, the rotating device 4 is rotatably connected in the second bracket 2, one end of the clamping mechanism 5 is fixedly connected to the rotating device 4, and the cylinder head is located inside the rotating device 4, so that The other end of the clamping mechanism 5 is telescopically connected to the cylinder head. In this way, the first bracket 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com