Straightness and twist angle detection method for turnout of high-speed railway and detection device thereof

A twist angle and detection device technology, which is applied to high-speed rail turnout straightness and twist angle detection devices, high-speed rail turnout straightness and twist angle detection fields, can solve problems such as low measurement accuracy, unintuitive detection results, and slow detection speed. High measurement accuracy, fast detection speed, and the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

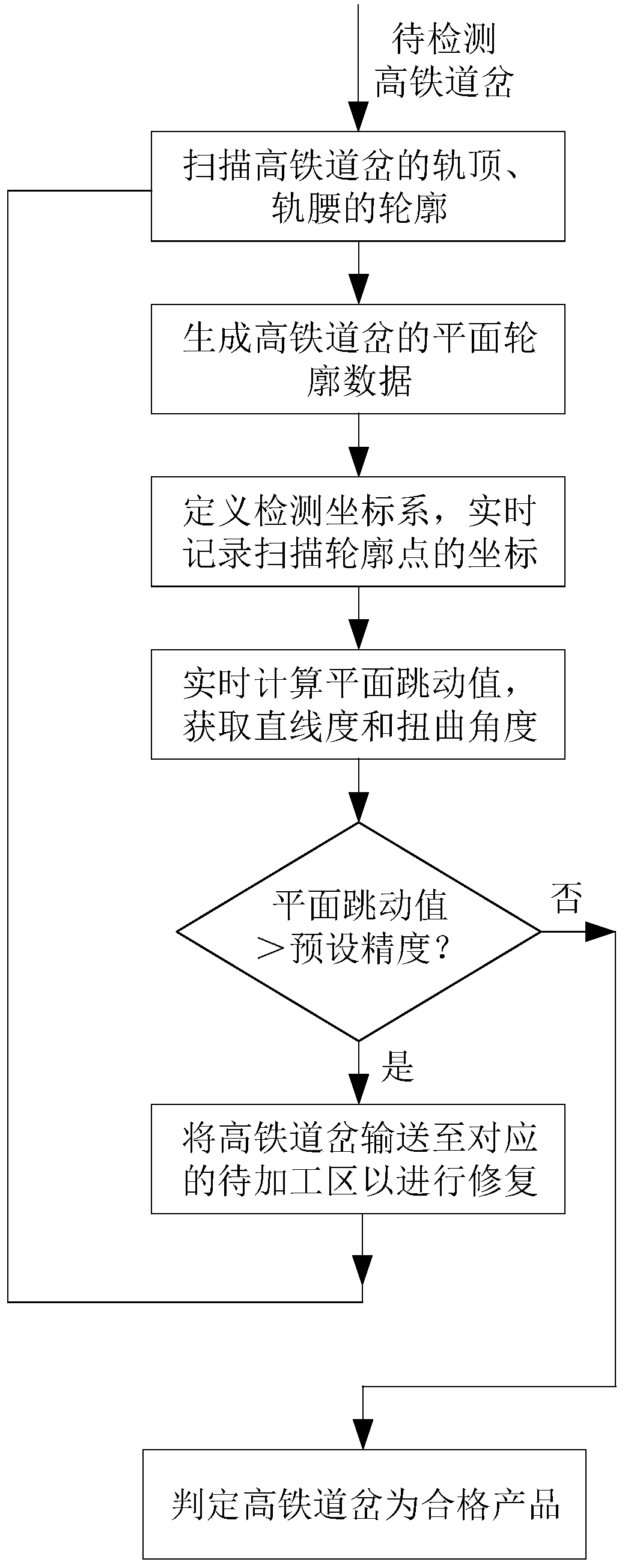

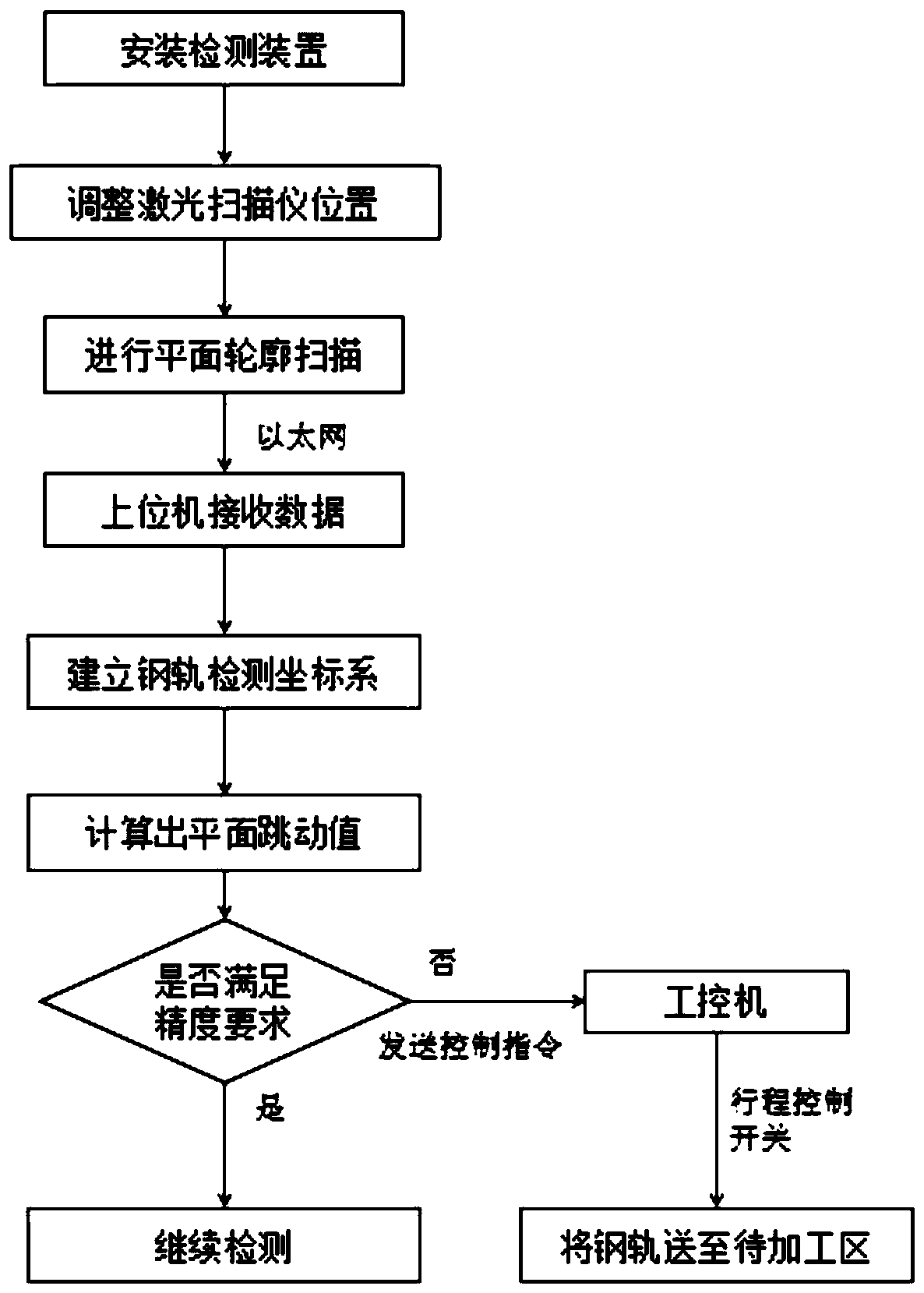

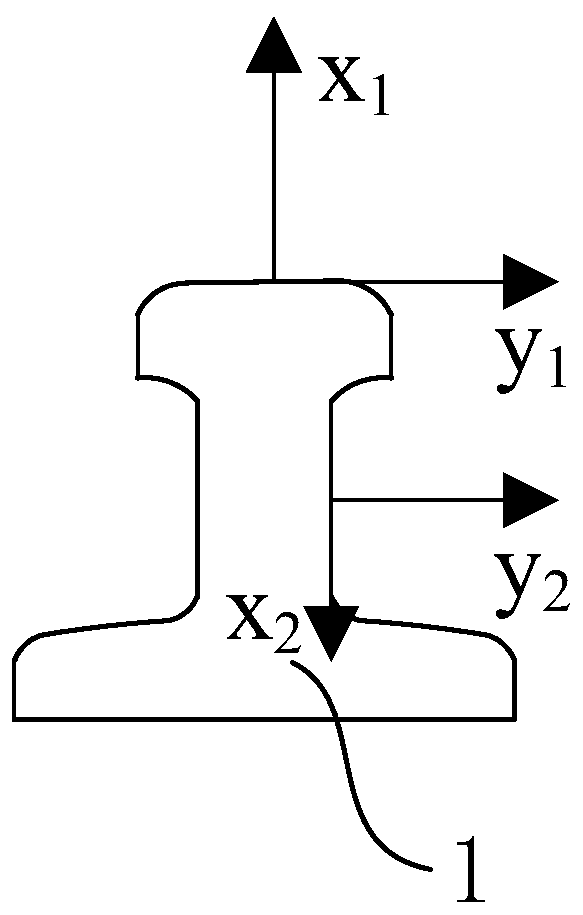

[0057] see figure 1 , figure 2 as well as image 3 , the present embodiment provides a method for detecting the straightness and twist angle of a high-speed rail switch, the method is used to detect the straightness and twist angle of a high-speed rail switch 1 on a turnout production line, and includes the following steps.

[0058] Step (a): First emit the line structured light covering the detection position to the rail top and rail waist of the high-speed rail turnout 1, and then drive the turnout production line to drive the high-speed rail switch 1 to move to scan the rail top and rail waist of the high-speed rail turnout 1 contour. In the actual detection process, corresponding detection structures can be installed on both sides of the turnout production line to scan and detect the high-speed railway turnout 1 located on the turnout production line. Since the line-structured light irradiates on the high-speed railway switch 1, a light band will be formed, and the cor...

Embodiment 2

[0069] see Figure 5 , Figure 6 as well as Figure 7 , this embodiment provides a high-speed rail switch straightness and twist angle detection device, which can apply the high-speed rail switch straightness and twist angle detection method in Embodiment 1. Wherein, the detection device includes a detection mechanism 1, an analysis calculation module and a control module, and may also include a data transmission module.

[0070] There are at least two detection mechanisms one, and the two detection mechanisms one are arranged on opposite sides of the high-speed railway switch 1 respectively. Each detection mechanism one includes a base 2 , a detection arm 3 and a detection head 4 . The base 2 is arranged on the opposite side of the high-speed railway switch 1 . In this embodiment, two bases 2 are directly fixed on opposite sides of the high-speed railway switch 1 respectively, and are symmetrical with respect to the high-speed railway switch 1 . The detection arm 3 inclu...

Embodiment 3

[0080] see Figure 10 , this embodiment provides a high-speed rail turnout straightness and twist angle detection device, the detection device is similar to the detection device in Embodiment 2, the difference is that the detection arm 3 of this embodiment is different, that is, the embodiment is removed in this embodiment Lock screw one 33 and lock screw two 34 in 2, and set up drive assembly. The drive assembly belongs to the detection mechanism one, and is used to drive the positioning rod one 31 to rotate relative to the base 2, and is used to drive the positioning rod two 32 to rotate relative to the positioning rod one 31, so that the other end of the positioning rod two 32 moves around the high-speed rail switch 1.

[0081] In this embodiment, the driving assembly includes a servo motor one 35 and a servo motor two 36 . The servo motor one 35 is fixed on the base 2, and is used to drive the positioning rod one 31 to rotate. The second servo motor 36 is fixed on the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com