Antimony-containing high-strength and high-toughness aluminum-silicon alloy and preparation method thereof

An aluminum-silicon alloy, high-strength and high-toughness technology, which is applied in the field of alloys, can solve the problems that the high-strength and high-toughness aluminum-silicon alloy cannot be satisfied, the influence relationship is not clear, and it is difficult to expand the application range of the antimony element aluminum-silicon alloy, so as to improve the strength and toughness , increased branching and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing an antimony-containing high-strength and high-toughness aluminum-silicon alloy described in the above technical solution, comprising the following steps:

[0046] (1) Provide primary aluminum-silicon alloy melt;

[0047] (2) adding an intermediate alloy to the primary aluminum-silicon alloy melt described in step (1), performing a metamorphic reaction to obtain a metamorphic alloy feed liquid; then performing refining and casting in sequence to obtain an antimony-containing high-strength and high-toughness aluminum-silicon alloy;

[0048] The master alloy is an aluminum-antimony master alloy or a mixture of an aluminum-antimony master alloy and an aluminum-zirconium master alloy.

[0049] The invention provides a primary aluminum-silicon alloy melt, preferably melting a raw material alloy containing silicon and aluminum to obtain a primary aluminum-silicon alloy melt. In the present invention, the melting tempe...

Embodiment 1

[0060] Melt 420g of Al-20Si alloy at 700°C for 20 minutes to obtain an aluminum alloy melt; heat up to 740°C, preheat 80g of Al-5Sb master alloy to 200°C, add it to the aluminum alloy melt, and stir for 2 minutes Afterwards, the metamorphic reaction was carried out at 740°C for 8 minutes, and the melt obtained after the metamorphic reaction was cooled to 720°C, left to stand for 3 minutes, and 10gC was added 2 Cl 6 , standing still for 15 minutes for refining and degassing, removing slag, and casting the melt into a mold preheated to 220°C to obtain an antimony-containing aluminum-silicon alloy containing 0.8wt% Sb.

[0061] According to the ASTM E8M-04 standard, the tensile strength and elongation of the obtained aluminum-silicon alloy were measured. It was determined that the tensile strength of the antimony-containing aluminum-silicon alloy containing 0.8 wt% Sb obtained in Example 1 was 154.12 MPa, and the elongation was 1.97%.

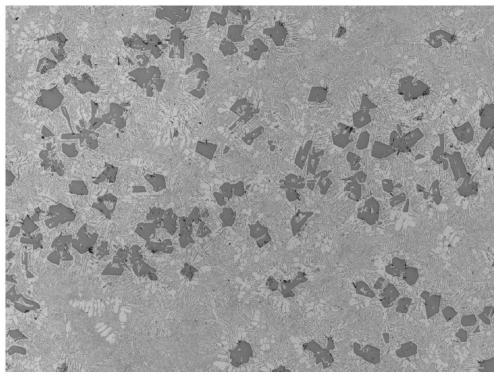

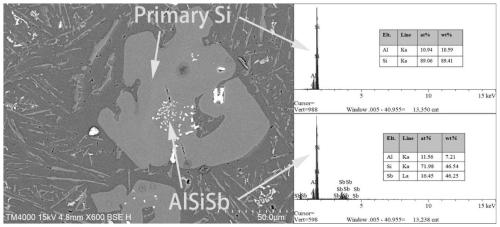

[0062] The antimony-containing aluminum-s...

Embodiment 2

[0064] Melt 405g of Al-20Si alloy at 700°C for 20 minutes to obtain molten aluminum alloy; heat up to 740°C, preheat 15g of Al-10Zr master alloy and 80g of Al-5Sb master alloy to 200°C, then add to the aluminum alloy In the melt, after stirring for 2 minutes, carry out a metamorphic reaction at 740°C for 15 minutes, cool the melt obtained after the metamorphic reaction to 720°C, let it stand for 3 minutes, and add 10gC 2 Cl 6 , standing for 15 minutes for refining and degassing, slag removal, and casting the melt into a preheated mold at 220°C to obtain an antimony-containing aluminum-silicon alloy containing 0.3wt.% Zr and 0.8wt.% Sb.

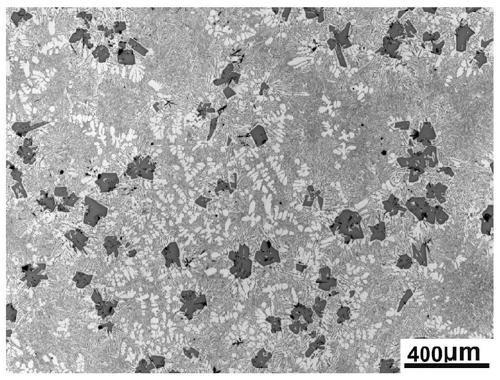

[0065] The tensile strength and elongation of the antimony-containing aluminum-silicon alloy containing 0.8 wt% Sb obtained in Example 2 were tested by the same test method as in Example 1. It is determined that the tensile strength of the antimony-containing aluminum-silicon alloy containing 0.3wt.% Zr and 0.8wt.% Sb obtained in Example 2 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com