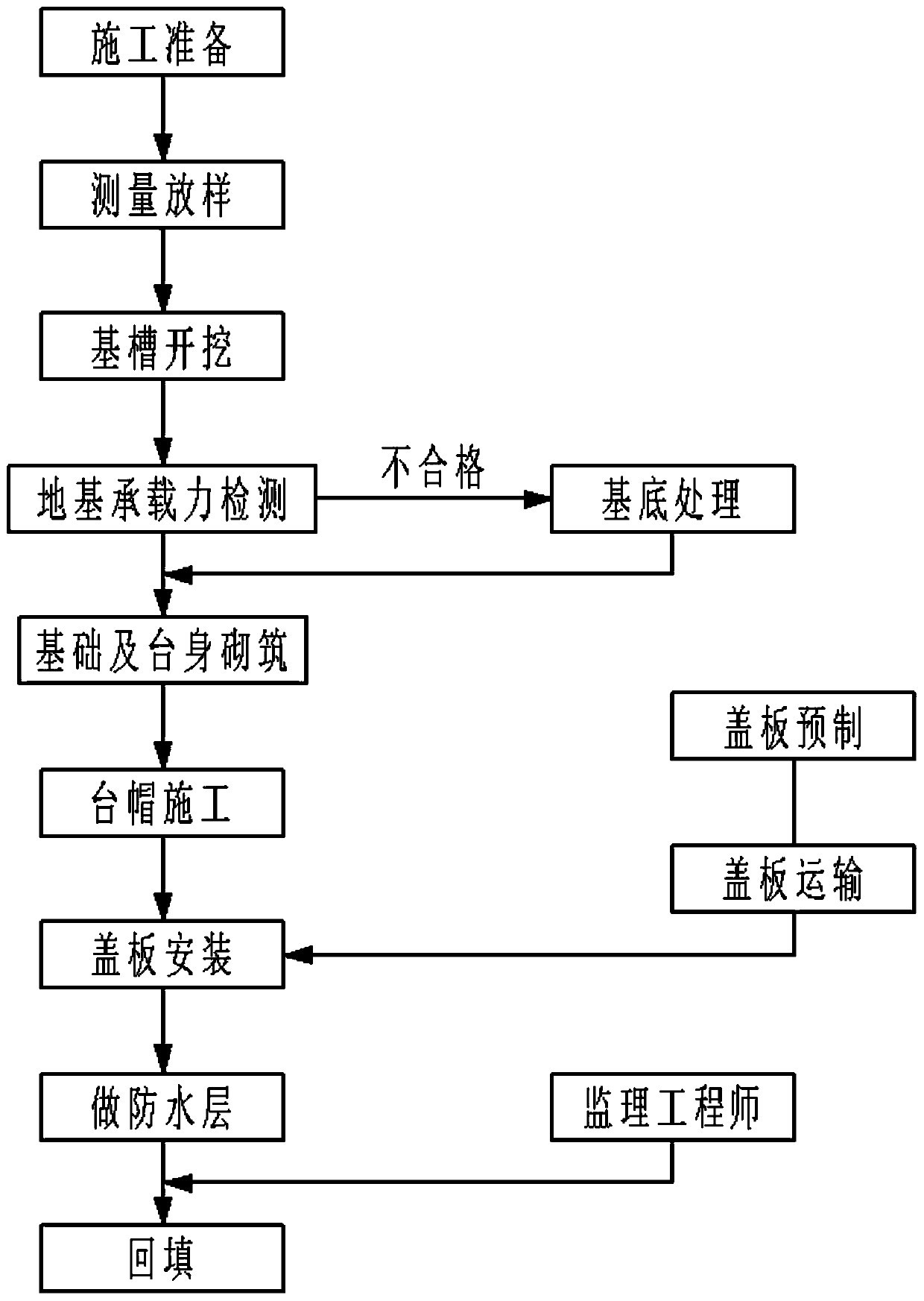

Cover plate culvert construction process

A construction technology and technology of cover plate culvert, applied in the direction of building, road bottom, etc., can solve construction difficulties and other problems, and achieve the effect of strong flood discharge capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

[0020] Such as figure 1 Shown, a kind of slab culvert construction technique is characterized in that comprising the following steps:

[0021] S1, measurement and setting out, according to the requirements of the design drawings, use the total station to stake out the center line, then sprinkle the base line with white lime according to the center line, determine the excavation side line, and indicate the elevation and excavation depth, and at the same time determine the position, direction, Positioning and laying out of the base size, elevation, etc., so that construction personnel can quickly identify the location during construction.

[0022] S2, Excavation of the foundation trench. Excavator excavation is used for excavation of the foundation trench, and dump trucks are operated together. When excavating the foundation trench,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com