Down-the-hole drill bit for drilling and reaming

A drill bit and down-the-hole technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of expensive equipment life, complex structure, etc., and achieve the effect of simple structure, high structural strength and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

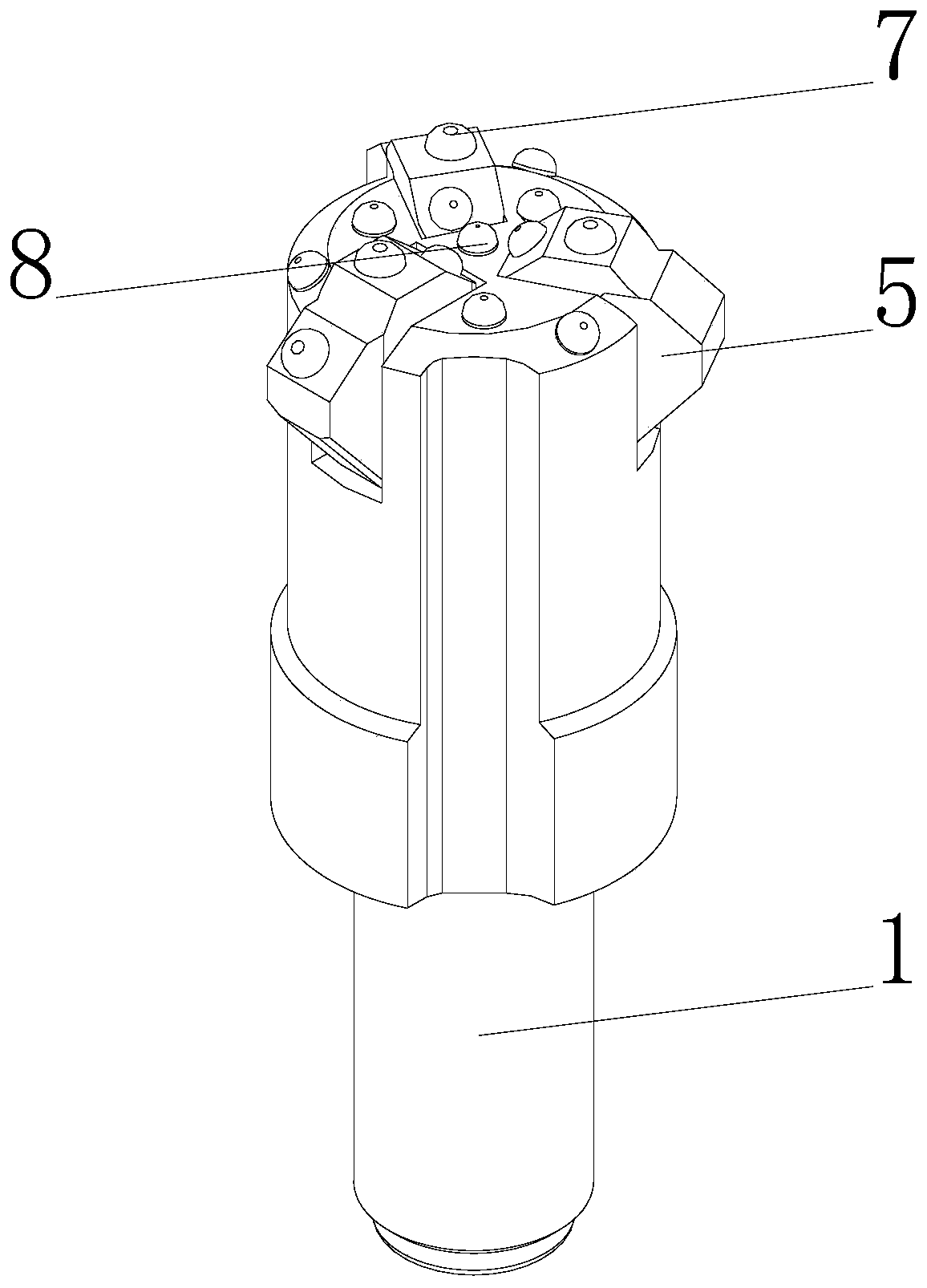

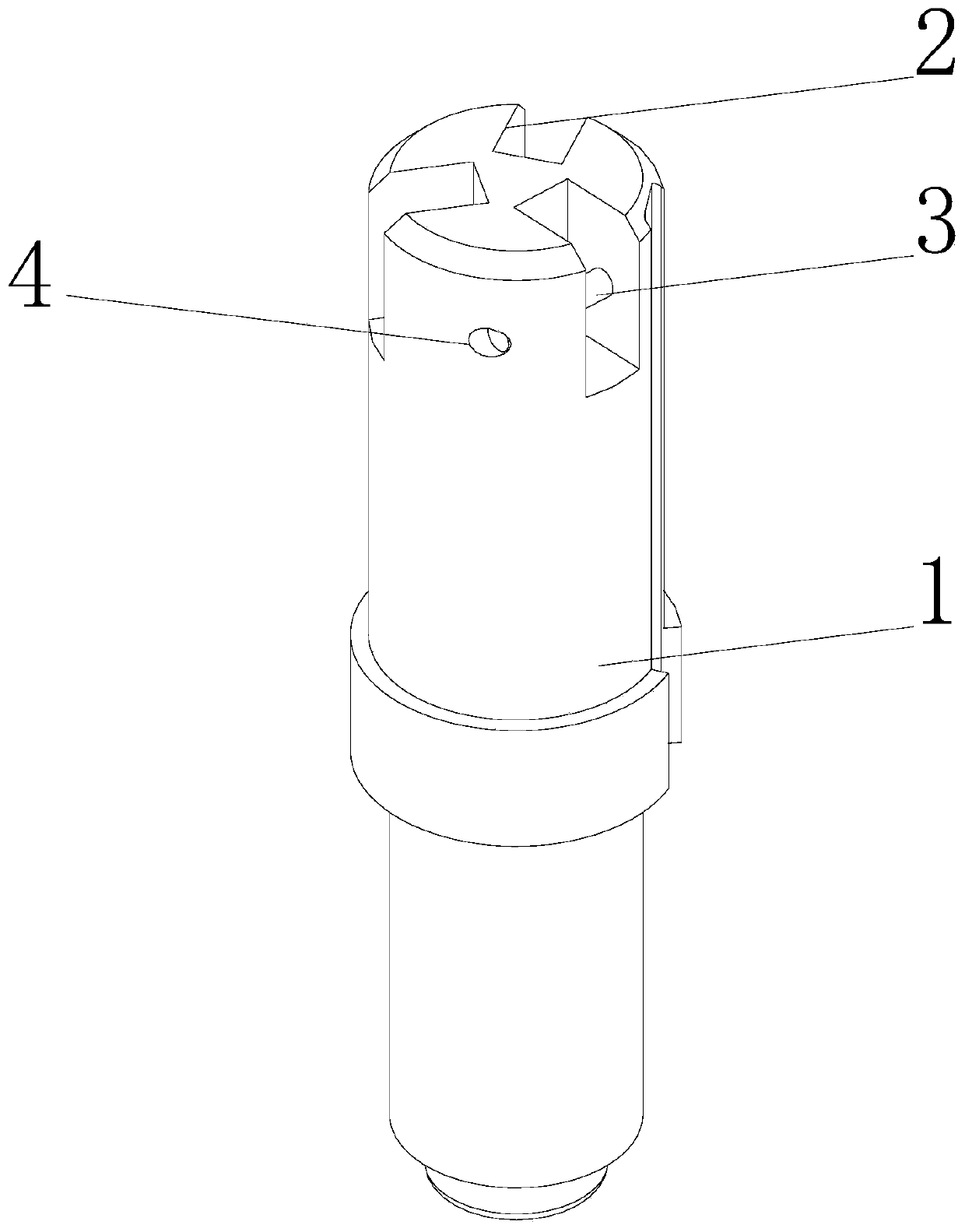

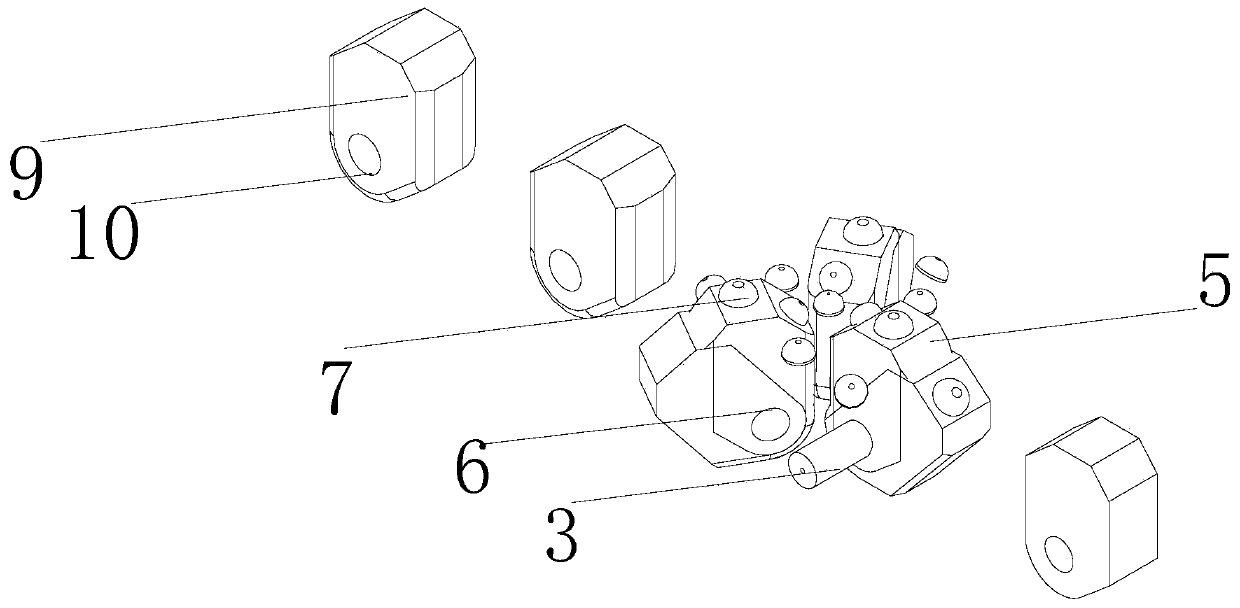

[0028] see Figure 1-3 , the present invention provides the following technical solutions: a down-the-hole drill for drilling and reaming, comprising a drill body 1, a gap 2 is provided on the drill body 1, and a socket 4 is opened on the side wall of the drill body 1, and the socket The inside of 4 is plugged with an unfolding and folding positioning column 3, and one end of the expanding and folding positioning column 3 passes through the gap 2 and is fixedly connected with the inner wall of the drill body 1, and the surface of the unfolding and folding positioning column 3 is rotationally connected with a first position located inside the gap 2. Movable reaming block 5, the top of the first movable reaming block 5 is fixed with a first alloy block 7, and the drill body 1 is fixed with a second alloy block 8.

[0029] In this embodiment, the drill body 1 is made of metal material, and the position and size of the notch 2 need to be uniformly adapted according to the diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com